Low-emission combustion chamber head part with oil way automatic regulating valve structure

A technology of automatic regulating valve and regulating valve, which is applied in the direction of combustion chamber, continuous combustion chamber, combustion method, etc., to achieve the effects of low emission, reducing the number of accessories, and changing the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

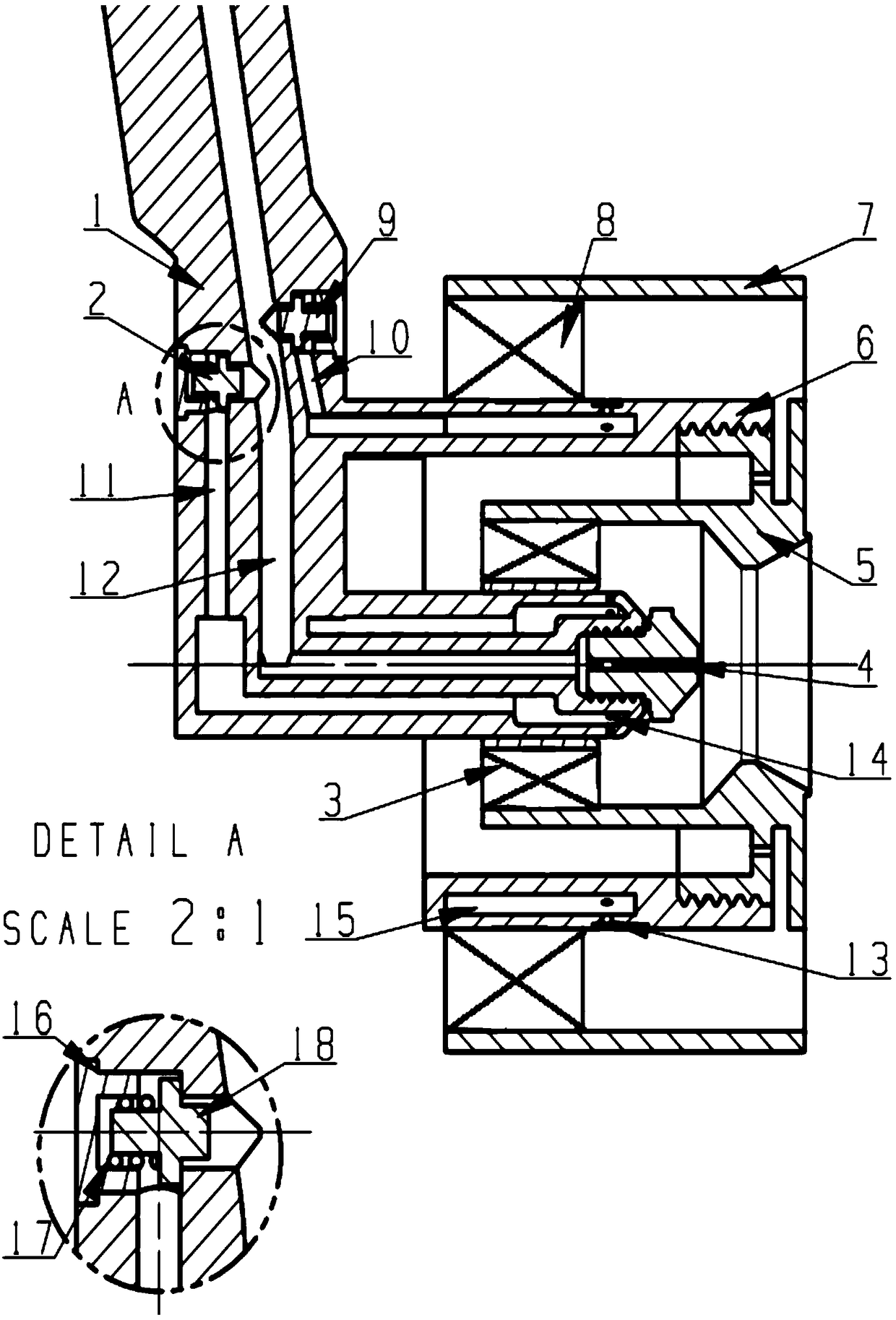

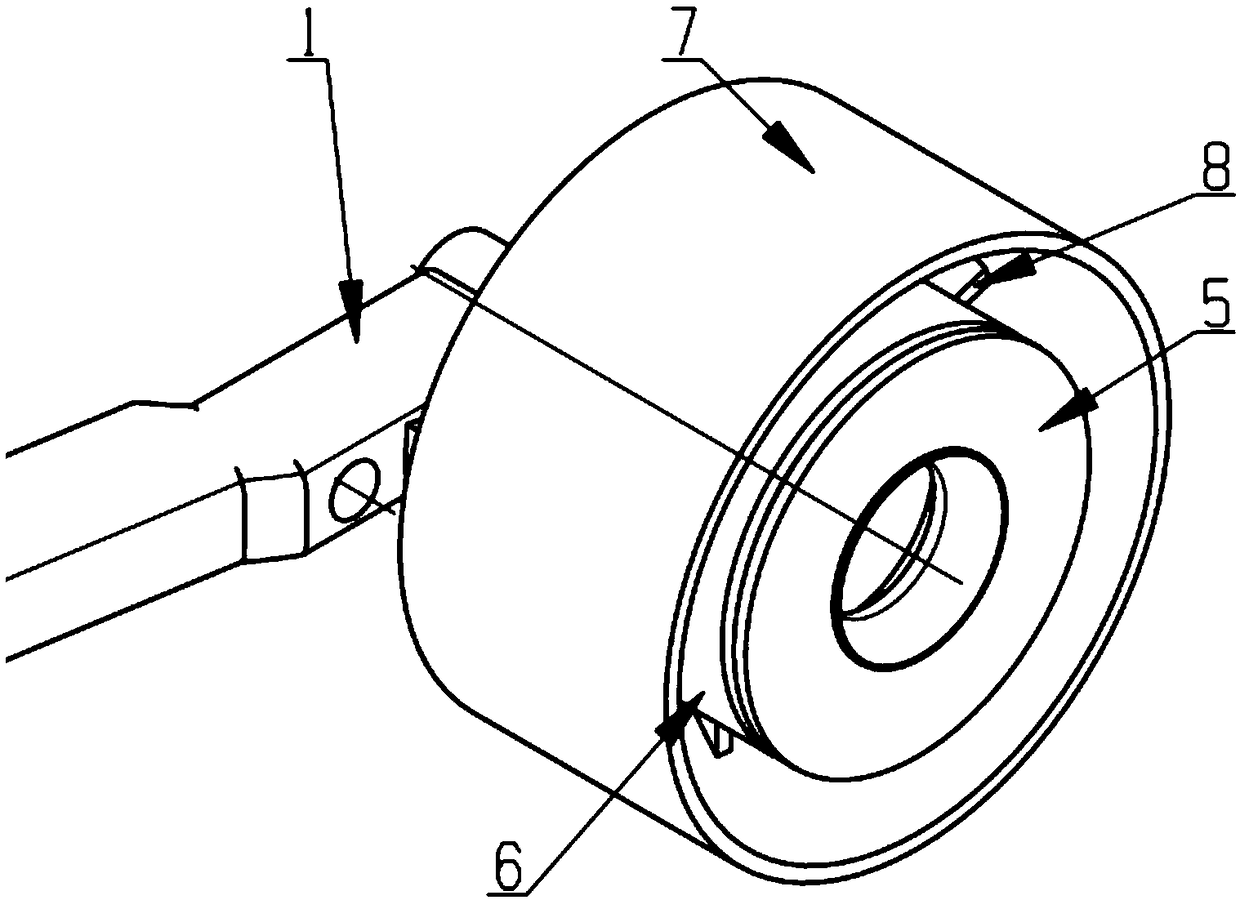

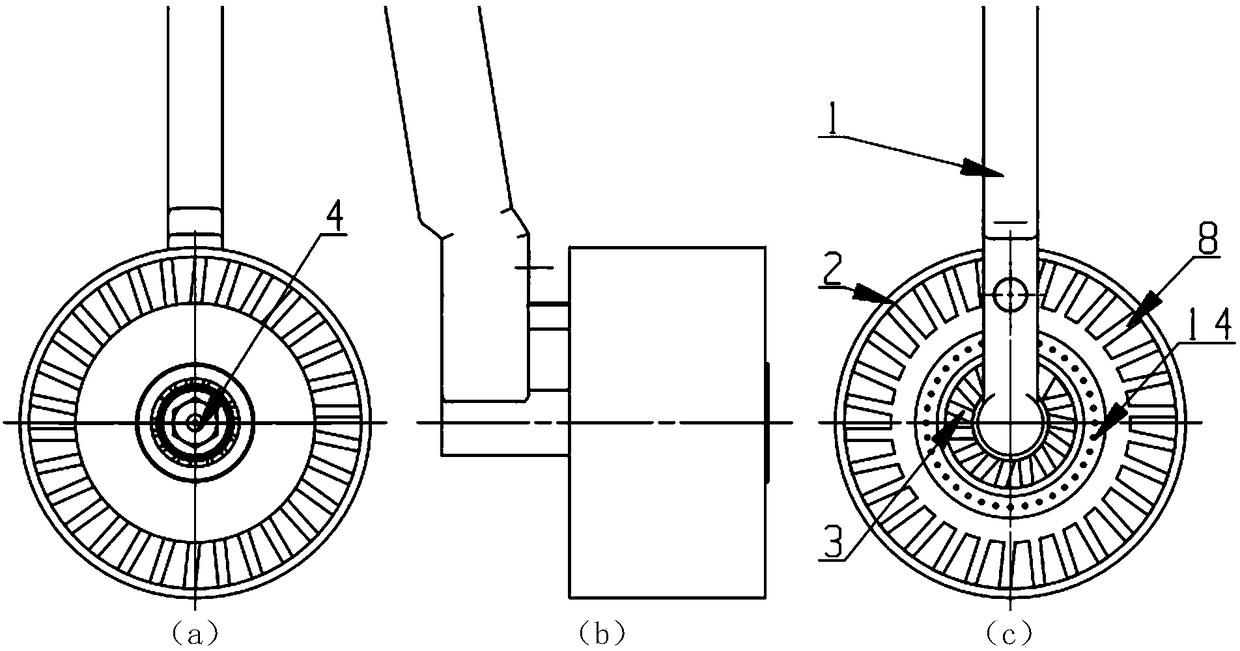

[0025] Such as figure 1 , figure 2 , image 3 As shown, it is a low-emission combustor head with an oil circuit automatic regulating valve structure described in the embodiment of the present invention. The general oil pipeline is adopted to automatically supply oil to the three oil circuits simultaneously. The combustion stage consists of two parts, among which the pre-combustion stage is a double oil circuit nozzle. Mainly composed of oil rod 1, pre-combustion stage main oil circuit regulating valve 2, pre-combustion stage cyclone 3, pre-combustion stage auxiliary oil circuit centrifugal nozzle 4, inter-stage section 5, inter-stage section connecting section 6, main combustion stage sleeve The barrel 7, the main fuel stage cyclone 8, and the main fuel stage oil circuit regulating valve 9 are composed. Among them, the oil rod 1 , the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com