High-power thermally superconducting plate-fin combined radiator

A thermal superconducting, combined technology, applied in the direction of semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc., can solve problems such as the inability to meet the heat dissipation of high-power devices, and achieve weight and thickness reduction, cost reduction, and strength. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

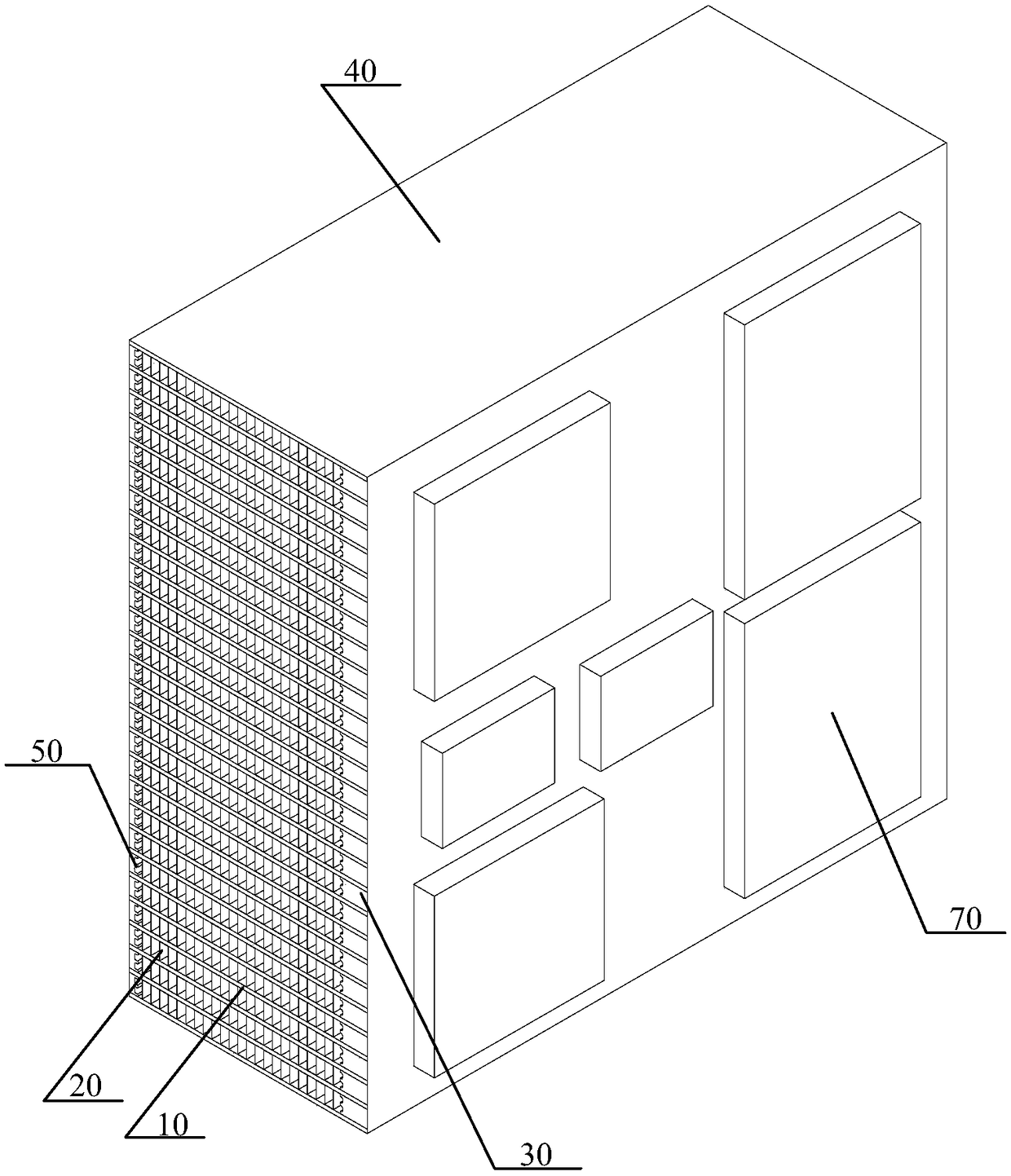

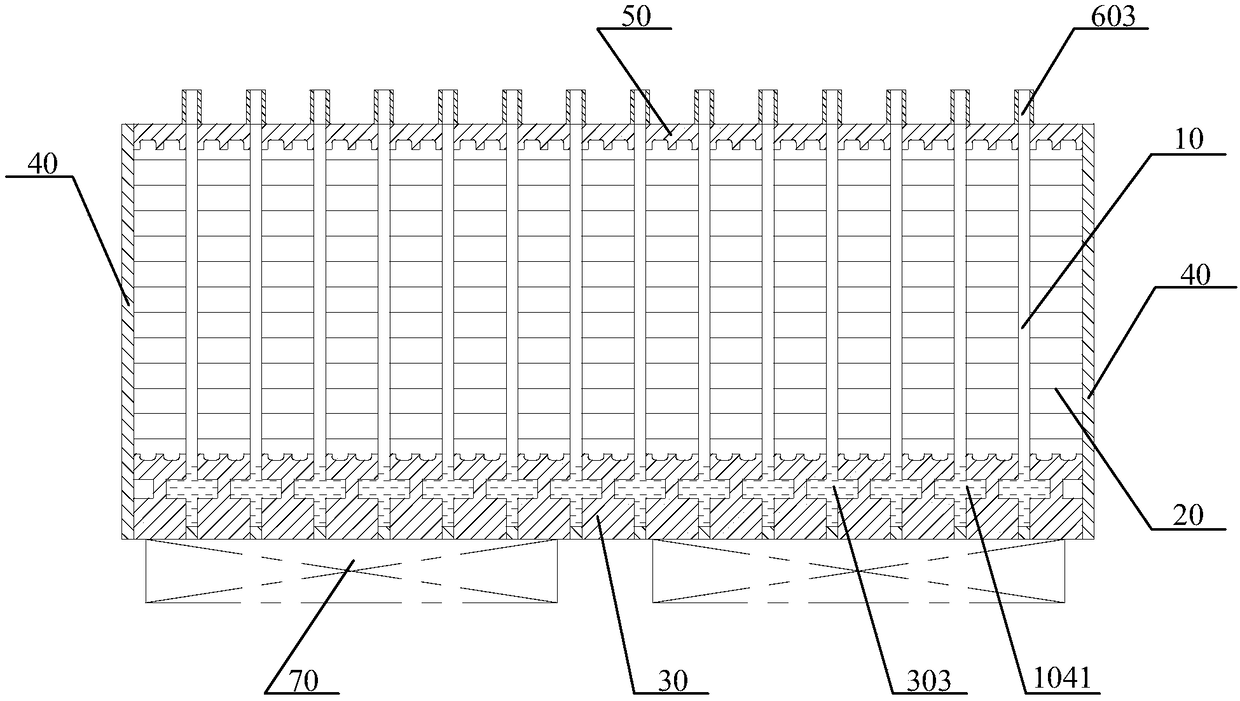

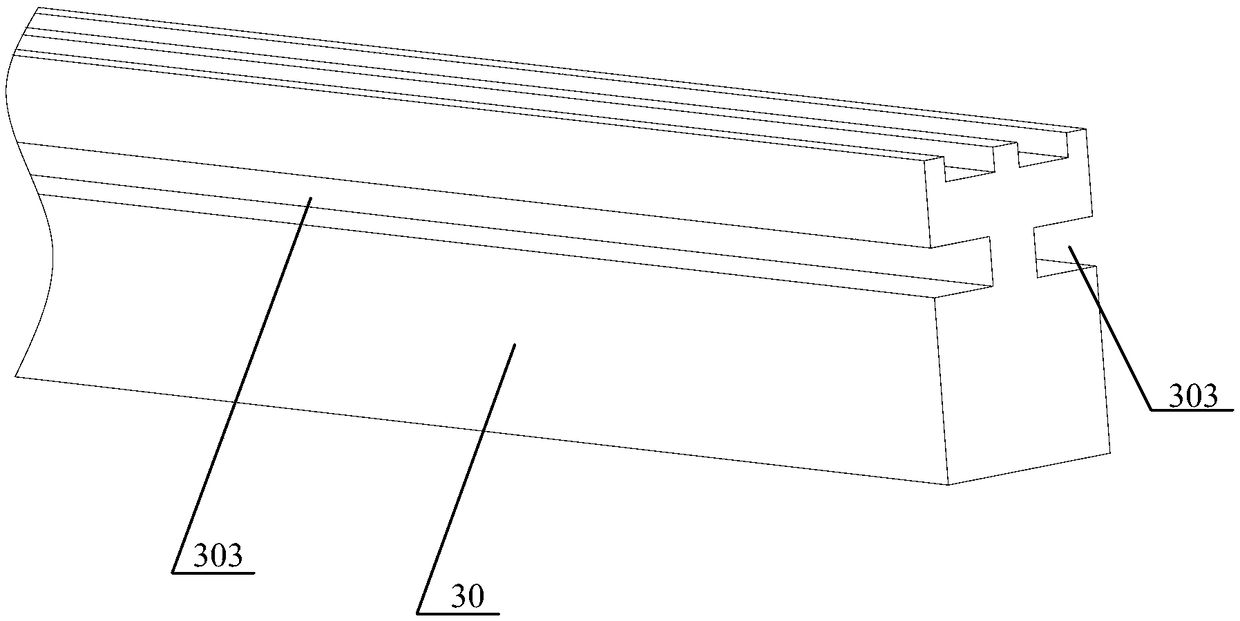

[0084] see Figure 1 to Figure 2 , the present invention provides a high-power thermal superconducting plate-fin combined radiator, the high-power thermal superconducting plate-fin combined radiator includes: several thermal superconducting plates 10 arranged at intervals, the thermal superconducting plates 10 is formed with interconnected heat transfer channels (not shown), the heat transfer channels are filled with heat transfer working fluid 1041; several bottom substrate spacers 30, the bottom substrate spacers 30 are located adjacent to the Between the thermal superconducting plates 10, and attached to the surface of the thermal superconducting plate 10; at least one side of the bottom substrate spacer 30 is provided with a groove 303 on the surface that is in contact with the thermal superconducting plate 10; The surface of the thermal superconducting plate 10 in contact with the bottom substrate spacer 30 is provided with a connection through hole 105 connecting the hea...

Embodiment 2

[0115] Please combine Figure 1 to Figure 20 refer to Figure 21 to Figure 25 , this embodiment also provides a high-power thermal superconducting plate-fin combined heat sink, the structure of the high-power thermal superconducting plate-fin combined heat sink described in this embodiment is the same as the high-power The structure of the thermal superconducting plate-fin combined radiator is roughly the same, and the difference between the two is that the high-power thermal superconducting plate-fin combined radiator described in this embodiment is compared with the high-power thermal superconducting radiator described in the first embodiment. A top connecting plate 60 is added to the thermal superconducting plate-fin combined radiator, and the top connecting plate 60 is located above the top substrate spacer 50 and the thermal superconducting plate 10; the extension direction of the top connecting plate 60 It is perpendicular to the surface of the thermal superconducting p...

Embodiment 3

[0118] Please combine Figure 1 to Figure 25 refer to Figure 26 to Figure 28, this embodiment also provides a high-power thermal superconducting plate-fin combined radiator, the structure of the high-power thermal superconducting plate-fin combined radiator described in this embodiment is the same as the high-power The structure of the thermal superconducting plate-fin combined radiator is roughly the same, the difference between the two is that the specific structure of the top connecting plate 60 is different, specifically: the top connecting plate 60 in the second embodiment is formed with a filling groove 60 and the filling hole 602 connected with the filling groove 601, the filling groove 601 extends along the length direction of the top communicating plate 60, and is connected with the conduction in each thermal superconducting plate 10 The heat passages are all connected, that is, the top communication plate 60 in the second embodiment is formed with a filling groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com