a load tio 2 Preparation method of pps photocatalytic film

A technology of photocatalytic membranes and microporous membranes, applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problem of limited exposure of catalyst active sites and small contribution , single function and other problems, to achieve high crystallinity, improve catalytic efficiency, and high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The invention provides a loaded TiO 2 The preparation method (abbreviation method) of the PPS photocatalytic film is characterized in that the method may further comprise the steps:

[0023] 1) TiO 2 Preparation of precursor solution: Mix the composite solution of titanium source, sulfate, ethanol, water and hydrochloric acid, and stir until homogeneous at room temperature to obtain TiO 2 Precursor solution; TiO 2 The concentration of titanium source in the precursor solution is 1-500g / L, the concentration of sulfate is 1-50g / L; the volume ratio of the ethanol, water and hydrochloric acid is 2-6:1-3:1-3;

[0024] Preferably, the titanium source concentration is 10-200g / L, the sulfate concentration is 2-10g / L, and the volume ratio of ethanol, water and hydrochloric acid is 3-5:1-3:1-3;

[0025] The titanium source is at least one of tetrabutyl titanate, titanium tetrachloride, titanium sulfate, titanium trichloride, isopropyl titanate, titanocene dichloride, titanium ...

Embodiment 1

[0032] 1) Mix titanium tetrachloride, ammonium sulfate, ethanol, water and hydrochloric acid at a volume ratio of 2:1:1 at room temperature and stir until homogeneous to obtain TiO 2 Precursor solution; TiO 2 The concentration of titanium source in the precursor solution is 50g / L, and the concentration of sulfate is 1g / L;

[0033] 2) Wet the PPS microporous membrane in ethanol, then transfer to a 20% nitric acid solution and stir at 20°C for 4 hours.

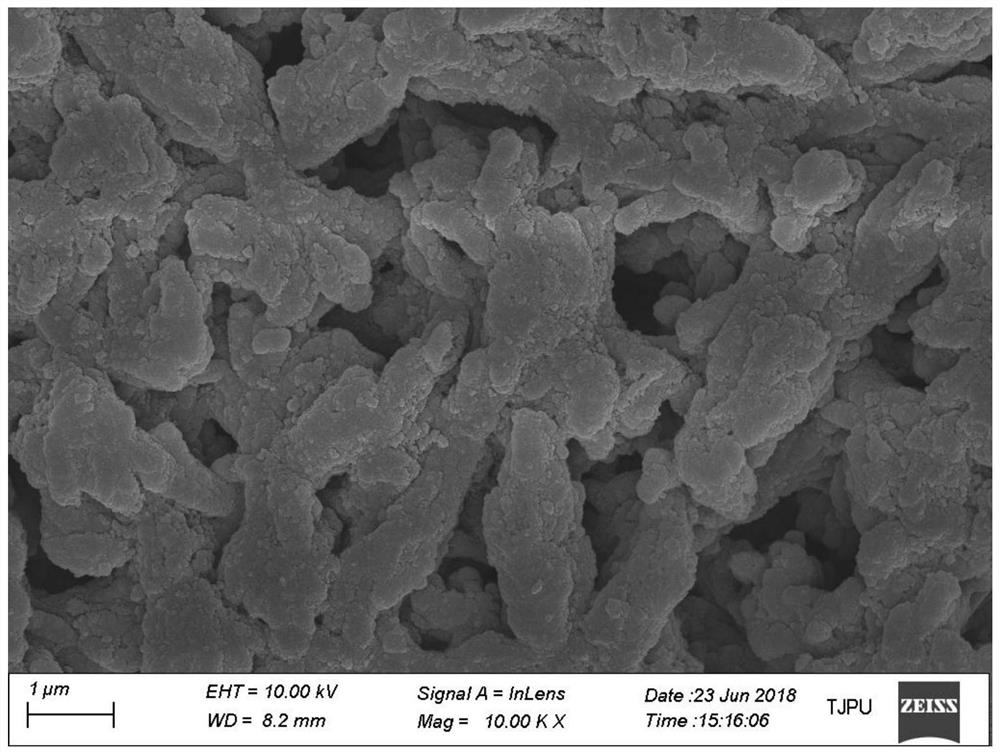

[0034] 3) Put 20cm 2 The obtained pretreated PPS microporous membrane was immersed in 20ml of precursor solution and transferred to a hydrothermal reaction kettle for hydrothermal reaction for 24 hours at a reaction temperature of 220°C. The resulting membrane was washed with deionized water and dried in an oven Get PPS@TiO within 24 hours 2 photocatalytic film.

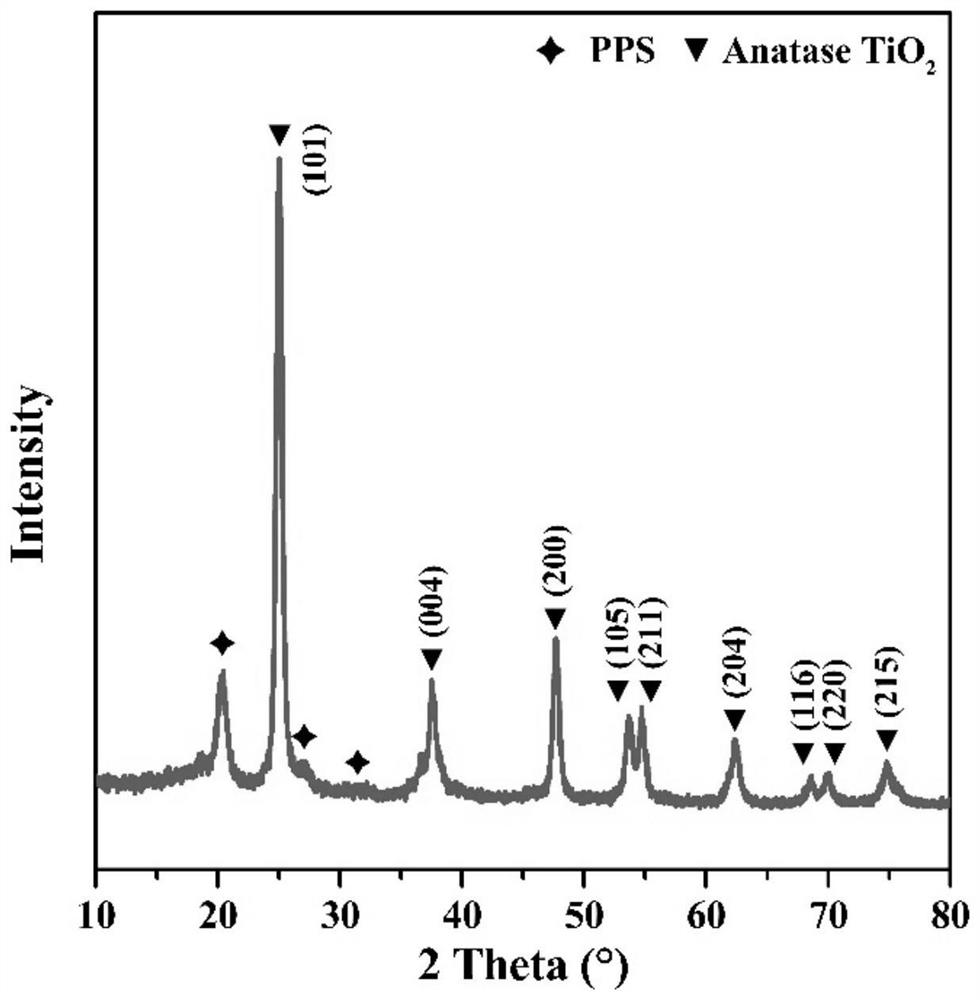

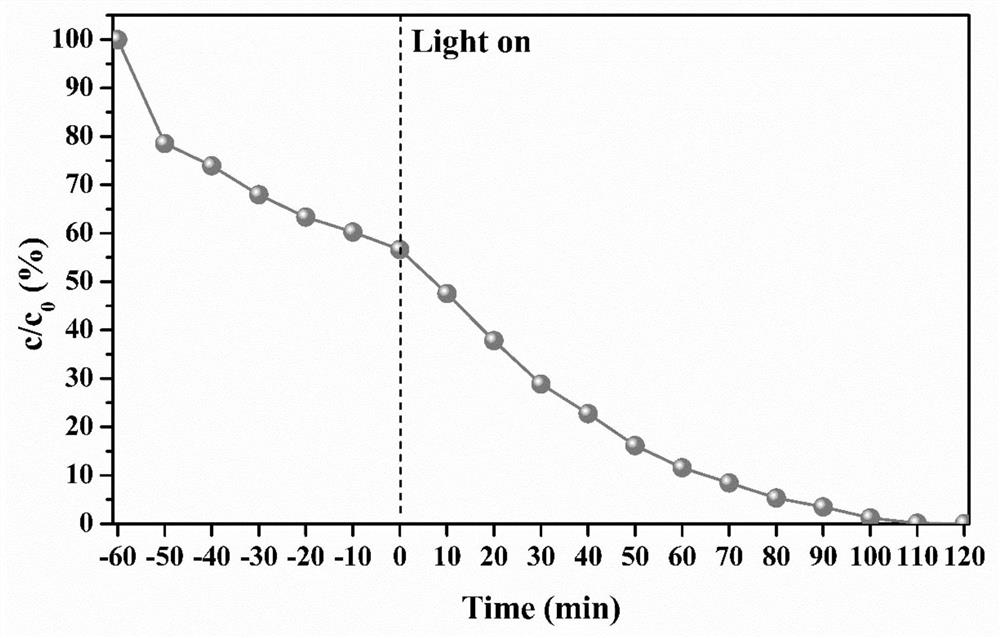

[0035] After testing, PPS@TiO 2The porosity of the photocatalytic film was 78.1%, and the loading rate of TiO2 was 19.2%. The photocatalytic performance was dete...

Embodiment 2

[0037] 1) Mix tetrabutyl titanate, ammonium sulfate, ethanol, water and hydrochloric acid at a volume ratio of 4:1:2 at room temperature and stir until homogeneous to obtain TiO 2 Precursor solution; TiO 2 The concentration of titanium source in the precursor solution is 150g / L, and the concentration of sulfate is 5g / L;

[0038] 2) Wet the PPS microporous membrane in ethanol, then transfer to a 10% nitric acid solution and stir at 50°C for 1 hour.

[0039] 3) Put 20cm 2 The obtained pretreated PPS microporous membrane was immersed in 10ml of precursor solution and transferred to a hydrothermal reaction kettle for hydrothermal reaction for 12 hours at a reaction temperature of 180°C. The resulting membrane was washed with deionized water and dried in an oven Get PPS@TiO within 24 hours 2 photocatalytic film.

[0040] After testing, PPS@TiO 2 The porosity of the photocatalytic film was 73.4%, and the loading rate of TiO2 was 50.6%. The photocatalytic performance was measur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| load ratio | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com