Doming machine mold unloading control system and method

A technology of control system and drop plastic machine, applied in the direction of coating, etc., can solve the problems of not having intelligent and simple operation requirements, unable to meet the mass production of enterprises, and difficult to guarantee the quality of workpiece handicrafts, etc., to achieve unmanned Streamlined production, increased competitiveness, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

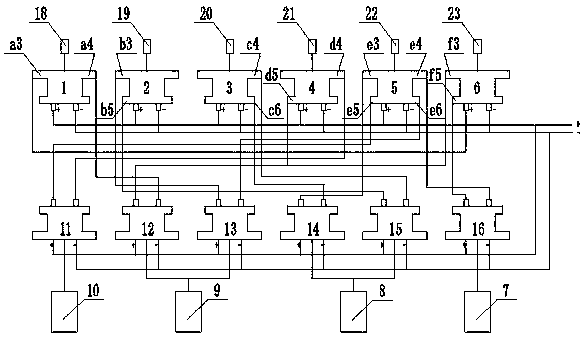

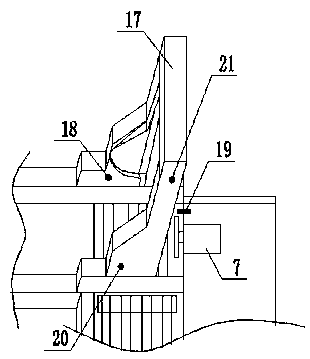

[0031] like Figures 1 to 7As shown in the figure, a mold unloading control system for a plastic dropping machine includes a weak current control system and a strong current control system. The weak current control system includes a signal processor A1, a signal processor B2, a signal processor C3, a signal processor D4, a signal processor Processor E5 and signal processor F6, the strong current control system includes relay A11, relay B12, relay C13, relay D14, relay E15 and relay F16, the signal processor A1 is provided with the first signal transmission pile Aa3 and The second signal transmission pile Aa4, the signal processor B2 is provided with a first signal transmission pile Bb3 and a second signal transmission pile Bb5, and the signal processor C3 is provided with a first signal transmission pile Cc4 and a second signal transmission pile Pile Cc6, the signal processor D4 is provided with the first signal transmission pile Dd4 and the second signal transmission pile Dd5...

Embodiment 2

[0034] like Figures 1 to 7 As shown in the figure, a mold unloading control system for a plastic dropping machine includes a weak current control system and a strong current control system. The weak current control system includes a signal processor A1, a signal processor B2, a signal processor C3, a signal processor D4, a signal processor Processor E5 and signal processor F6, the strong current control system includes relay A11, relay B12, relay C13, relay D14, relay E15 and relay F16, the signal processor A1 is provided with the first signal transmission pile Aa3 and The second signal transmission pile Aa4, the signal processor B2 is provided with a first signal transmission pile Bb3 and a second signal transmission pile Bb5, and the signal processor C3 is provided with a first signal transmission pile Cc4 and a second signal transmission pile Pile Cc6, the signal processor D4 is provided with the first signal transmission pile Dd4 and the second signal transmission pile Dd...

Embodiment 3

[0041] like Figures 1 to 7 As shown in the figure, a mold unloading control system for a plastic dropping machine includes a weak current control system and a strong current control system. The weak current control system includes a signal processor A1, a signal processor B2, a signal processor C3, a signal processor D4, a signal processor Processor E5 and signal processor F6, the strong current control system includes relay A11, relay B12, relay C13, relay D14, relay E15 and relay F16, the signal processor A1 is provided with the first signal transmission pile Aa3 and The second signal transmission pile Aa4, the signal processor B2 is provided with a first signal transmission pile Bb3 and a second signal transmission pile Bb5, and the signal processor C3 is provided with a first signal transmission pile Cc4 and a second signal transmission pile Pile Cc6, the signal processor D4 is provided with the first signal transmission pile Dd4 and the second signal transmission pile Dd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com