Universal polyurethane foam stabilizer and preparation method thereof

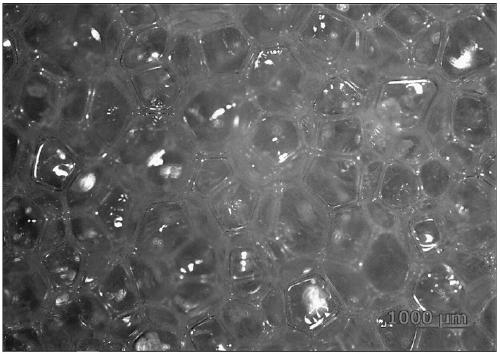

A polyurethane foam and foam stabilizer technology, which is applied in the field of polyurethane foam stabilizer and its preparation, can solve the single structure design and preparation process requirements of polyurethane soft foam or hard foam stabilizer, and the use of polyurethane foam stabilizer Single, limited polyurethane foam foaming applicability and other problems, to achieve the effect of uniform cell size, uniform cell distribution, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

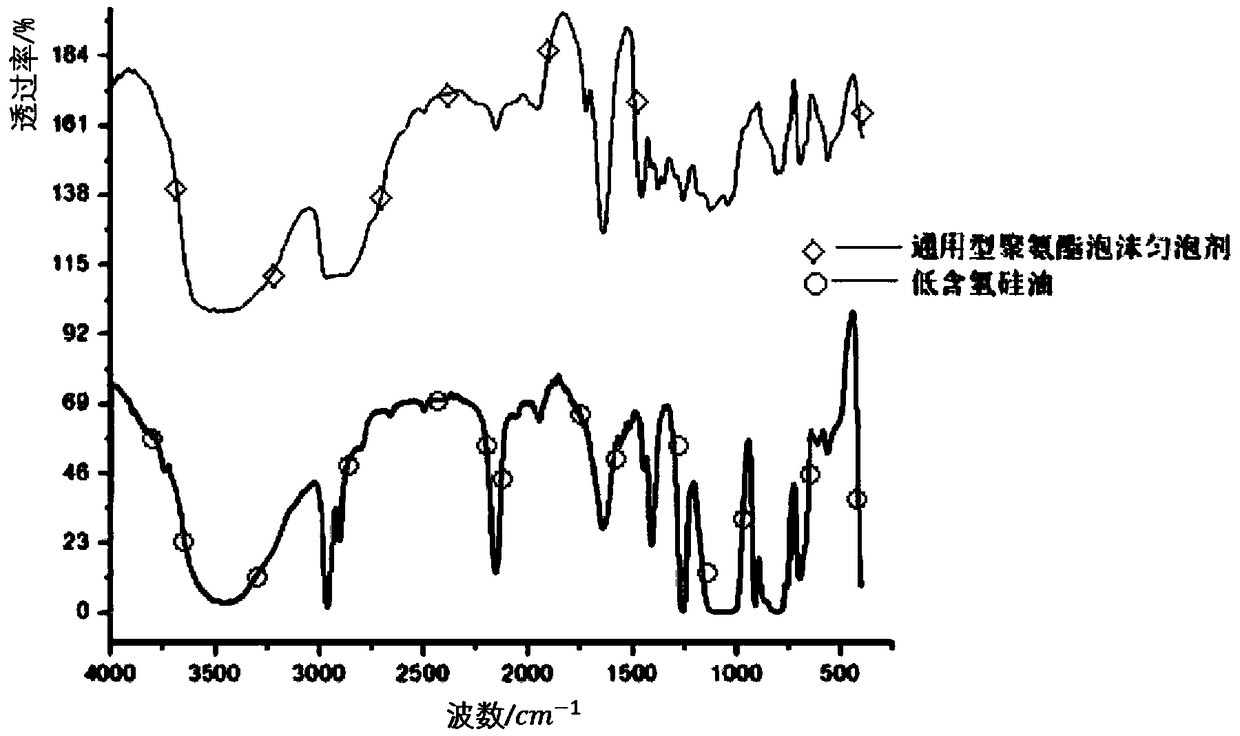

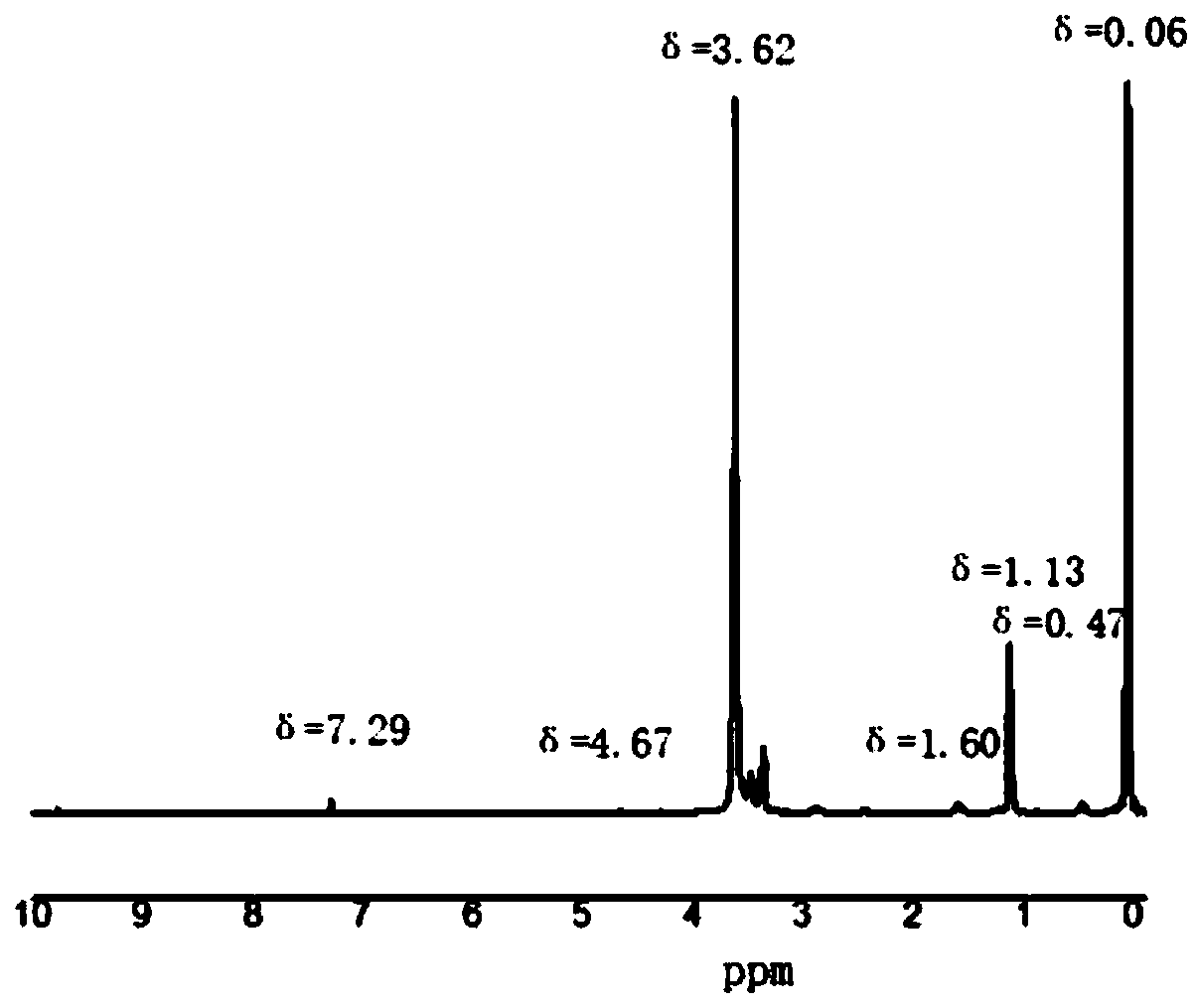

[0049] Preparation of low hydrogen silicone oil:

[0050] Mix 78 parts of octamethylcyclotetrasiloxane with 20 parts of high hydrogen-containing silicone oil, dehydrate at 60°C and -0.1MPa for 1.5 hours, and add 3 parts of strong acid macroporous ion exchange under the protection of high-purity nitrogen Resin, after the viscosity of the system increases visually, add 2 parts of end-capping agent hexamethyldisiloxane, keep it at 70°C for 3 hours, remove unreacted low molecular weight at 135°C at -0.1MPa, cool and filter to obtain a transparent Low hydrogen silicone oil.

Embodiment 2

[0052] Preparation of low hydrogen silicone oil:

[0053] Mix 89 parts of octamethylcyclotetrasiloxane with 9 parts of high hydrogen-containing silicone oil, dehydrate at 70°C and -0.1MPa for 0.5h, and add 4 parts of strong acid macroporous ion exchange under the protection of high-purity nitrogen Resin, after the viscosity of the system increases visually, add 1 part of end-capping agent hexamethyldisiloxane (MM), keep it at 60°C for 5 hours, remove unreacted low molecular weight at -0.1MPa at 140°C, cool and filter, Obtain transparent low-hydrogen silicone oil.

Embodiment 3

[0055] Preparation of low hydrogen silicone oil:

[0056] Mix 83 parts of octamethylcyclotetrasiloxane with 15 parts of high hydrogen-containing silicone oil, dehydrate at 65°C and -0.1MPa for 1 hour, and add 5 parts of strong acid macroporous ion exchange resin under the protection of high-purity nitrogen , after the viscosity of the system increased visually, add 3 parts of end-capping agent hexamethyldisiloxane, react at 60°C for 5h, remove unreacted low molecular weight at -0.1MPa at 145°C, cool and filter to obtain transparent low-molecular-weight Hydrogen silicone oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com