Alloy technology of adding Ce into bearing steel for inhibiting formation of TiN compound inclusion

An alloy technology and composite inclusion technology, which is applied in the field of alloy technology where Ce is added to suppress the formation of TiN composite inclusions in bearing steel, can solve problems such as poor lattice matching, achieve simple methods, broad application prospects, and improve fatigue life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

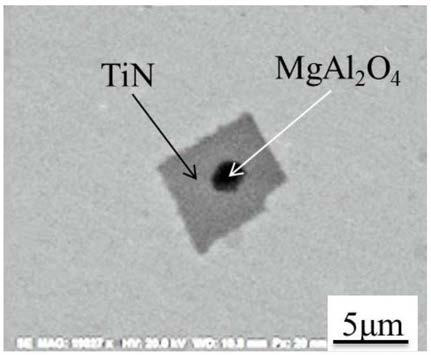

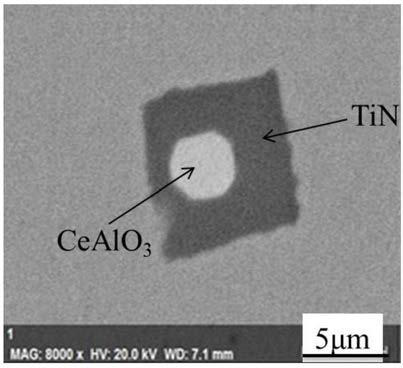

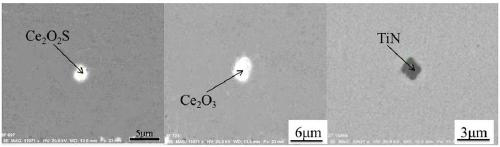

Image

Examples

Embodiment

[0060] According to the alloy process of adding Ce to bearing steel to suppress the formation of TiN composite inclusions according to the present invention, 5 groups of industrial examples were carried out. The smelting processes of the five groups of industrial examples are basically the same, the difference lies in the amount of rare earth Ce added, so they are described together here.

[0061] High-quality rare earth GCr15 bearing steel is produced in 30 (tons of steel) packages in a domestic steel factory. The production process is: EAF→LF→VD→die casting. The specific operation steps are as follows: (1) During the electric furnace smelting process, the oxygen blowing decarburization temperature during the oxidation period is 1612°C, the end point [C] is controlled at 0.74%, and the [Ti] content is controlled below 0.001%, and then the oxide slag is removed and remade Reduce the slag and carry out rough alloying to ensure that the main alloy elements such as [Cr] and [Mn] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com