Integrated assembly joint and method for isolation tier rubber bearing and column-beam slab system

A technology of rubber bearings and assembly nodes, which is applied in the direction of earthquake resistance, building components, building types, etc., can solve the complicated fixing and installation process of upper and lower connecting plates, the difficulty of installing and constructing pre-embedded connectors, and the difficulty in determining the position of pre-embedded components and other issues, to achieve the effect of improving the overall seismic performance, improving the construction quality, integrity and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

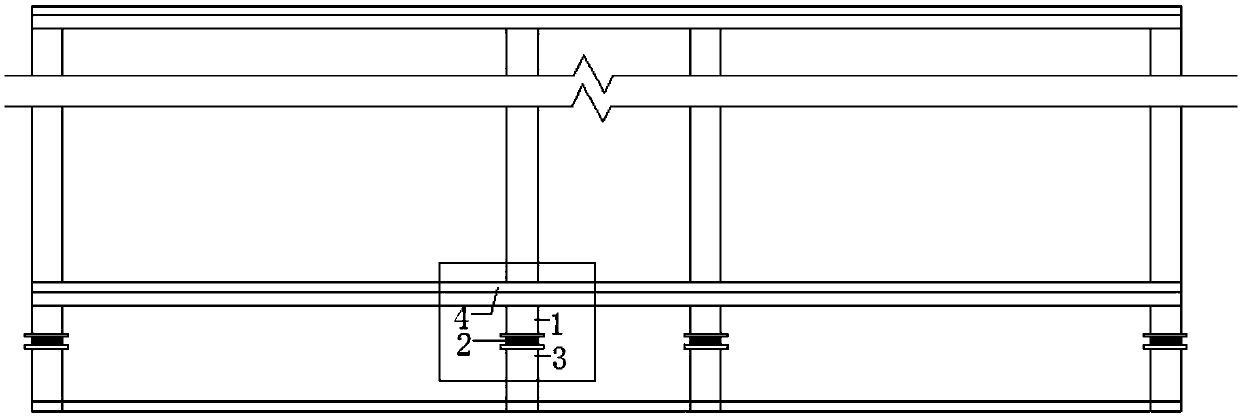

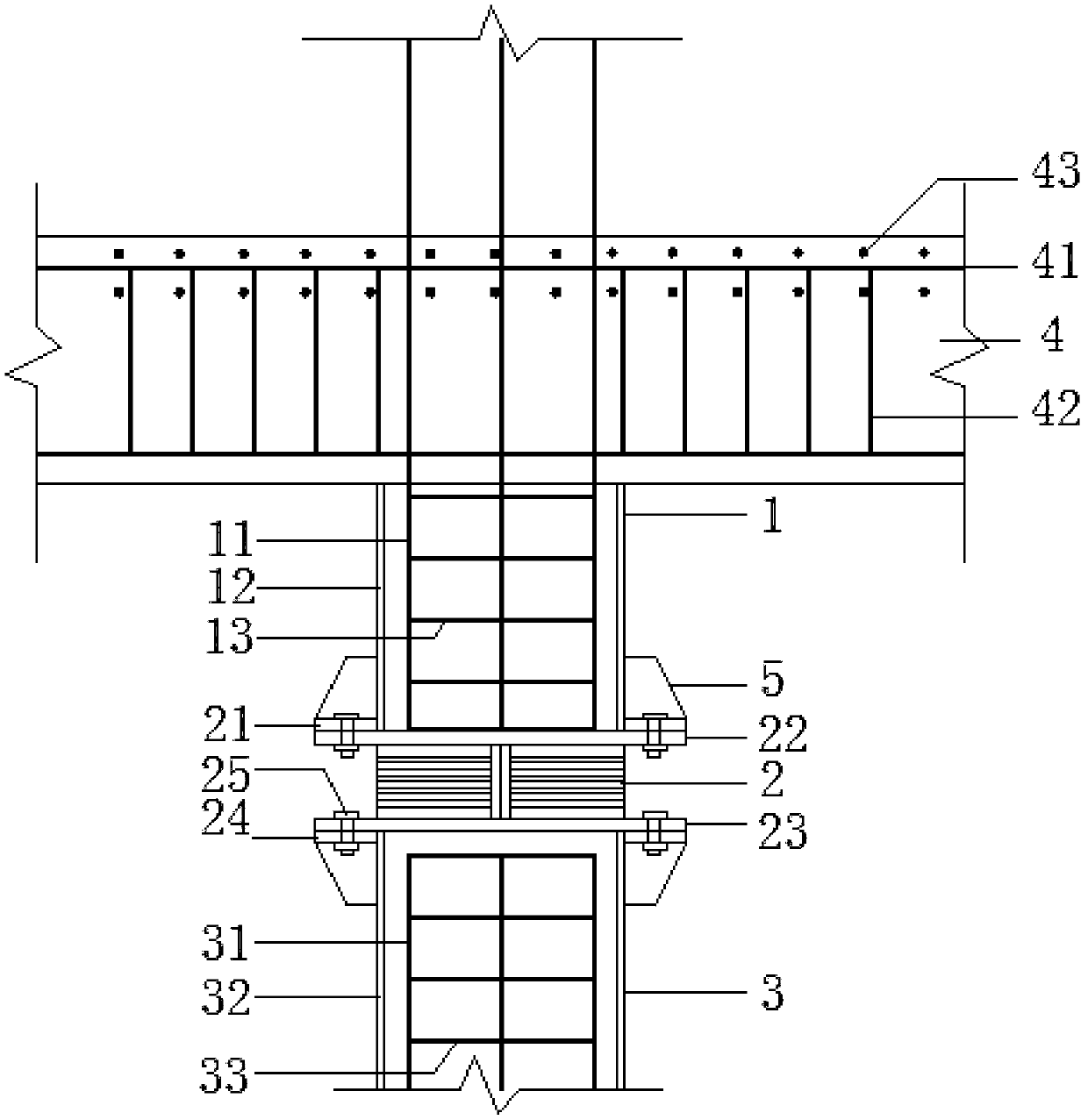

[0055] Such as Figures 1 to 7 As shown, an integrated assembly node of the rubber bearing of the seismic isolation layer and the column and beam-slab system includes an upper embedded plate 21, a rubber bearing 2 and a lower embedded plate 24, and the rubber bearing 2 is located between the upper embedded plate 21 and the lower embedded plate 24. Between the lower embedded boards 24. There is an upper nesting hole 212 on the upper embedded plate 21, and the lower end of the upper concrete filled steel tube column 1 is nested in the upper embedded hole 212 and then fixedly connected with the upper embedded plate 21. The size of the upper embedded hole 212 is slightly larger than the upper The outer dimension of the steel tube concrete column 1 is that the lower end surface of the upper steel tube concrete column 1 is flush with the lower end surface of the upper embedded plate 21 . Stiffeners 5 are arranged between the upper end surface of the upper embedded plate 21 and the ...

Embodiment 2

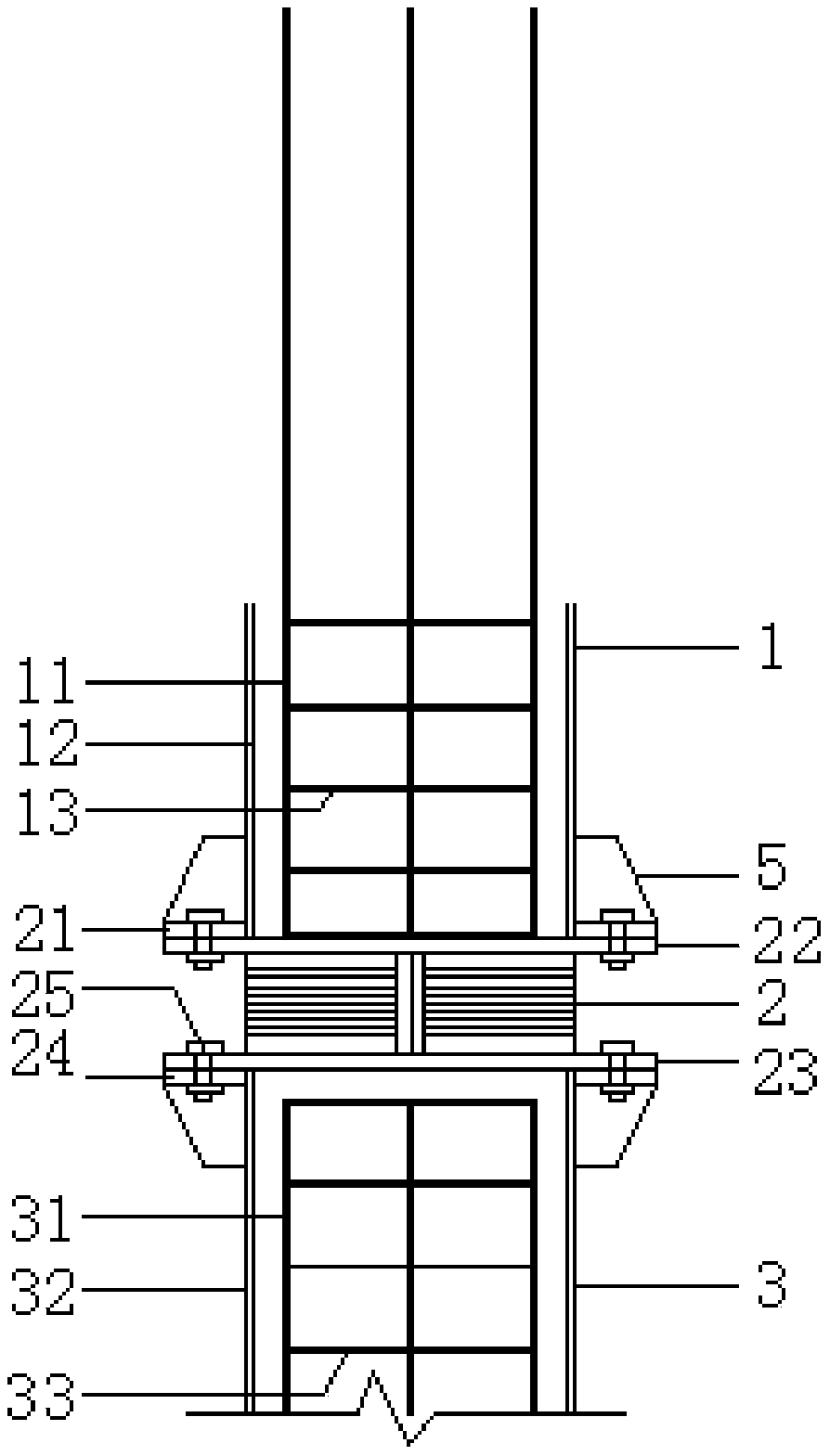

[0079] Such as Figure 8 , 9 As shown in , 10, an integrated assembly node of the rubber bearing of the seismic isolation layer and the column and beam-slab system includes an upper embedded plate 21, a rubber bearing 2 and a lower embedded plate 24, and the rubber bearing 2 is located on the upper embedded plate 21 and the lower embedded board 24. There is an upper nesting hole 212 on the upper embedded plate 21, and the lower end of the upper concrete filled steel tube column 1 is nested in the upper embedded hole 212 and then fixedly connected with the upper embedded plate 21. The size of the upper embedded hole 212 is slightly larger than the upper The outer dimension of the steel tube concrete column 1 is that the lower end surface of the upper steel tube concrete column 1 is flush with the lower end surface of the upper embedded plate 21 . Stiffeners 5 are arranged between the upper end surface of the upper embedded plate 21 and the side wall of the upper concrete fill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com