Miniaturized four-directional industrial endoscope snake bone

An endoscope, four-direction technology, applied in the field of industrial production, can solve the problems of unsatisfactory control of snake bone movement, small internal space, large outer diameter, etc., and achieve the effects of convenient wire rope threading, uniform aperture, and reduced outer diameter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical solutions of the present invention clearer and clearer to those skilled in the art, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

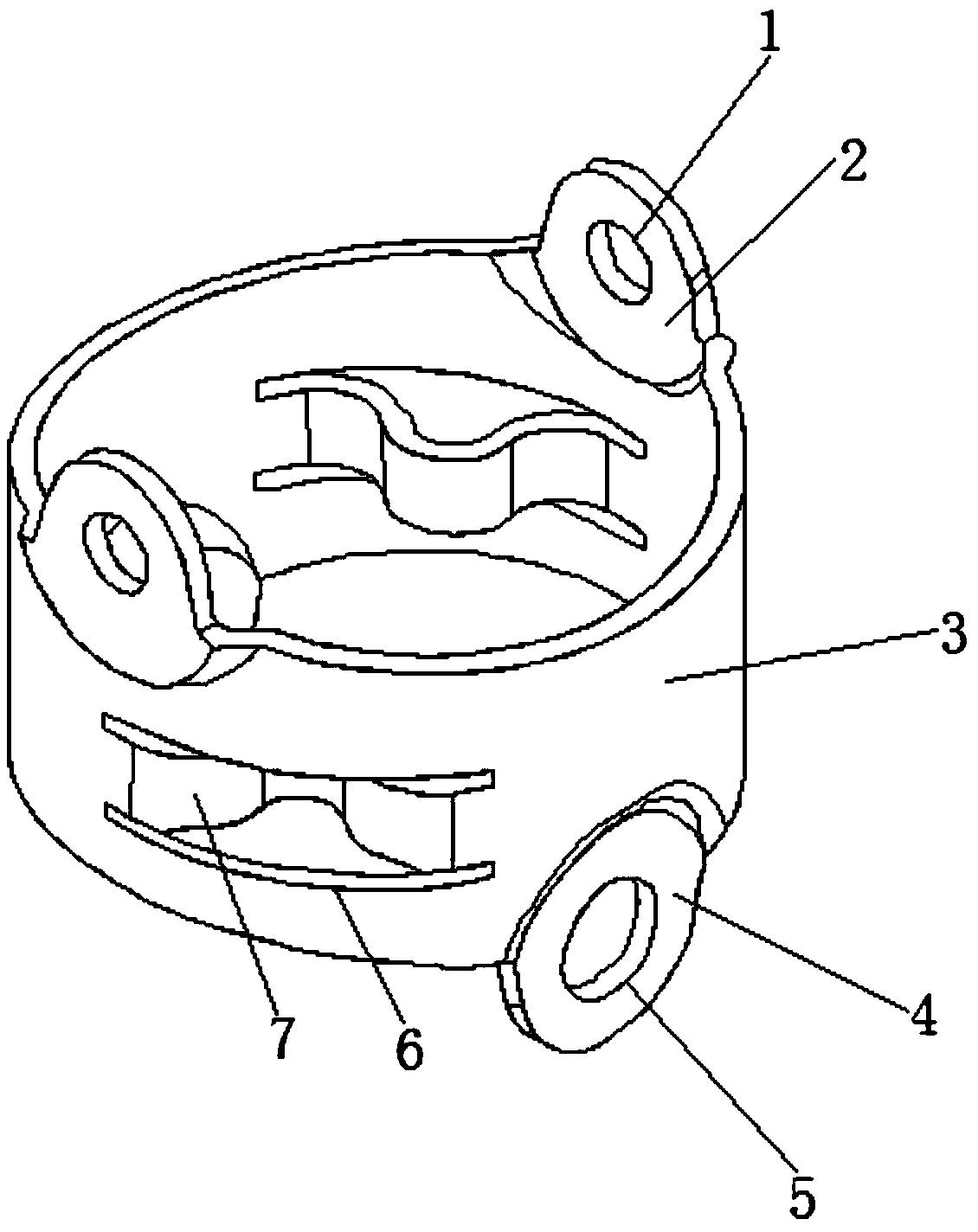

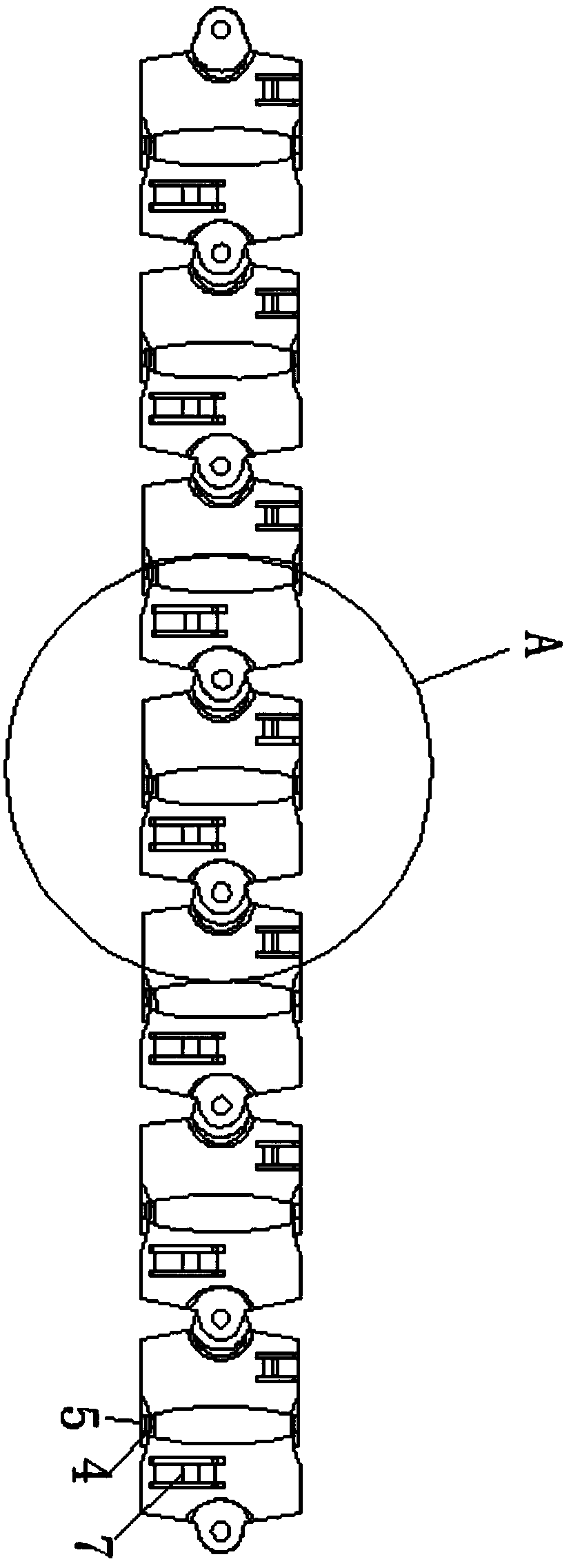

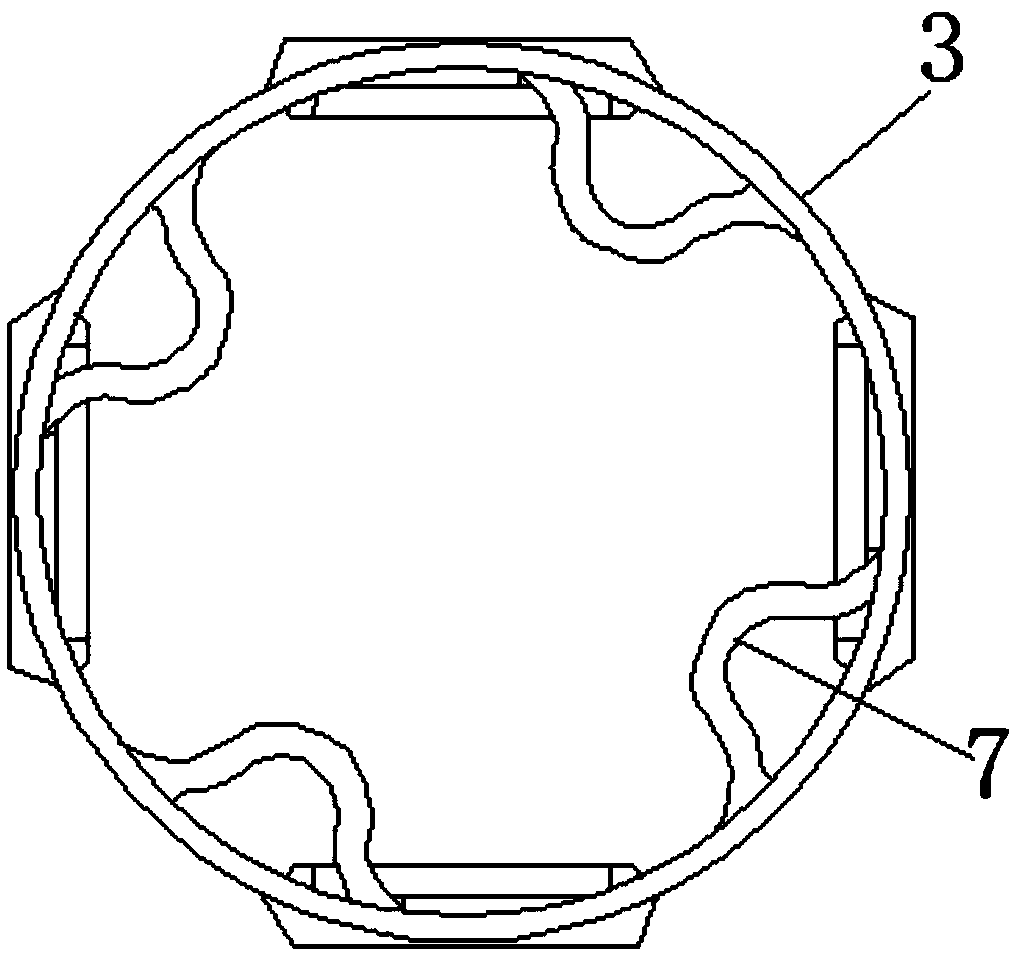

[0023] see Figure 1-4 , an embodiment provided by the present invention: a miniaturized four-way industrial endoscope snake bone, including a snake bone joint ring 3, lugs 2 are installed on both sides of the top of the snake bone joint ring 3, and the middle position of the lug 2 is Lug through-holes 1 are provided at the bottom of the snake-bone joint ring 3, concave ears 4 are installed on both sides of the bottom of the snake-bone joint ring 3, and the middle position of the concave ear 4 is provided with a concave-ear through-hole 5, and the middle position of the outer side of the snake-bone joint ring 3 is uniformly arranged There is a side through hole 6, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com