Preparation method of super hydrophilic/underwater super oleophobic self-cleaning paper towel fibrous membrane

An underwater super-oleophobic and self-cleaning technology, applied in separation methods, chemical instruments and methods, immiscible liquid separation, etc., can solve the problem that the surface is easily polluted or blocked by oil, cannot be recycled multiple times, and shortens the service life and other problems, to achieve good anti-fouling and recycling performance, excellent regenerative ability, and strong anti-fouling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) First, disperse 3g of P-25 powder in 100mL of 10M NaOH solution, stir for 10min, then transfer the mixed solution to a polytetrafluoroethylene reactor and heat it in an oven for 18h. After naturally cooling to room temperature, the collected product was washed with deionized water to neutrality, immersed in 50mL, 0.1M nitric acid solution, and dried to obtain titanic acid; finally, the titanic acid was heat-treated in air at a temperature of 500°C, The heating rate is 5°C / min, and the maintenance time is 3h to obtain TiO 2 Nanowires.

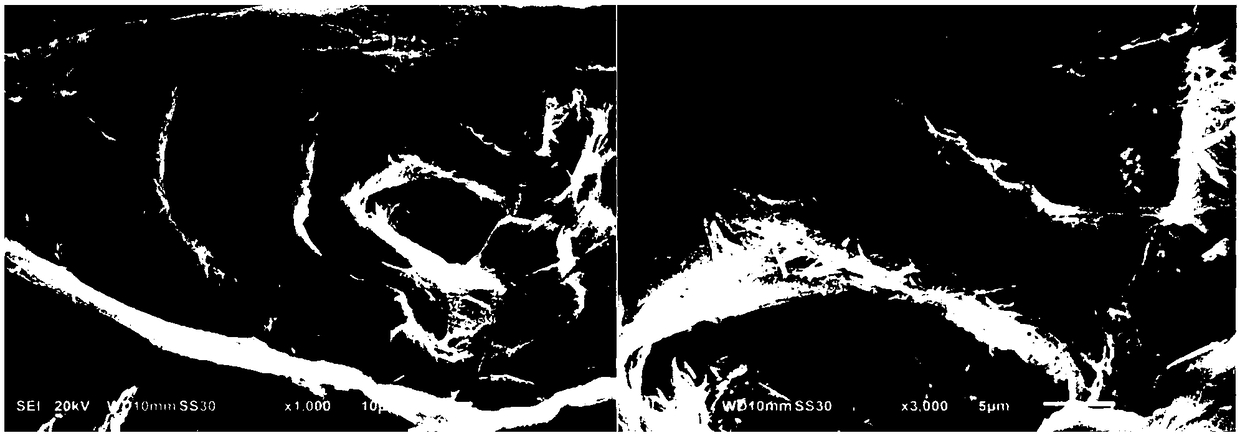

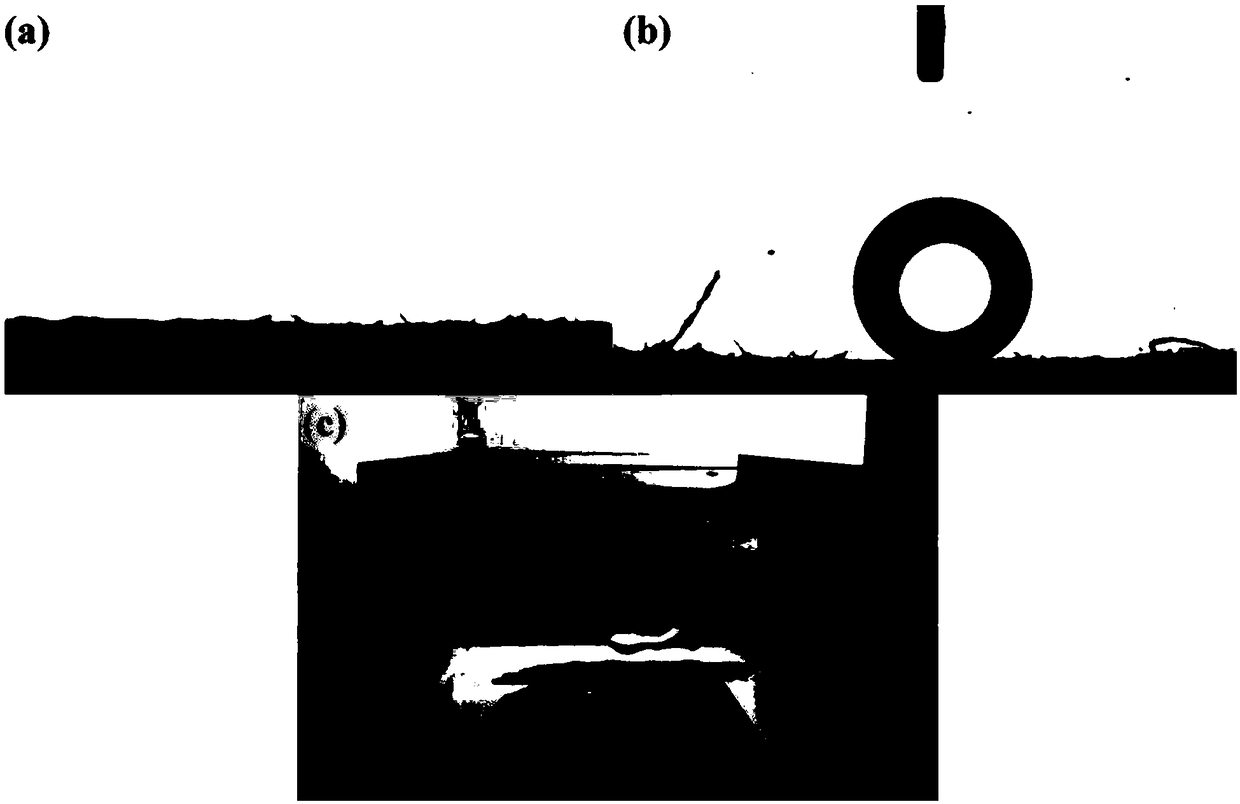

[0033] (2) First, 0.06g of TiO 2 Nanowires were dispersed in 50mL deionized water, ultrasonicated for 10min, and stirred for 30min to form a suspension; at the same time, 0.5g of paper towel was added to 50mL of deionized water, stirred for 30min, and then the paper towel dispersion was poured into TiO 2 In the suspension, 0.1211g of tris(hydroxymethyl)aminomethane and 0.2g of dopamine were added to the mixture at the same time, sti...

Embodiment 2

[0035] (1) First, disperse 3g of P-25 powder in 100mL of 10M NaOH solution, stir for 10min, then transfer the mixed solution to a polytetrafluoroethylene reactor and heat it in an oven for 20h, then cool it naturally After reaching room temperature, the collected product was washed with deionized water until neutral; immersed in 100mL, 0.1M nitric acid solution to obtain titanic acid; finally, the titanic acid was heat-treated in air at a temperature of 500°C and a heating rate of 5 ℃ / min, hold time is 3h, obtain TiO 2 Nanowires.

[0036] (2) 0.04g of TiO 2 Nanowires were dispersed in 50mL deionized water, sonicated for 10min, stirred for 30min to form a suspension; at the same time, 0.3g of paper towel was added to 50mL of deionized water, stirred for 30min, and then the paper towel dispersion was poured into TiO 2 In the suspension, 0.1211g of tris(hydroxymethyl)aminomethane and 0.2g of dopamine were added to the mixture at the same time, stirred for 6h, vacuum filtered, a...

Embodiment 3

[0038] (1) First, disperse 3g of P-25 powder in 100mL of NaOH solution with a concentration of 10M, stir for 10min, then transfer the mixed solution to a polytetrafluoroethylene reactor and heat it in an oven for 22h; After cooling to room temperature, the collected product was washed with deionized water until neutral, and then the sample was immersed in 150 mL of 0.1M nitric acid to obtain titanic acid; finally, the titanic acid was heat-treated in air at 500 °C, and the temperature was raised to The rate is 5°C / min, and the maintenance time is 3h to obtain TiO 2 Nanowires.

[0039](2) 0.02g of TiO 2 The nanowires were dispersed in 50mL deionized water for 10min and stirred for 30min to form a suspension. At the same time, 0.1g paper towel was added to 50mL deionized water and stirred for 30min. Then, the paper towel dispersion was poured into TiO 2 In the suspension, 0.1211g tris(hydroxymethyl)aminomethane and 0.2g dopamine were added to the mixture and stirred for 3 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com