Diatomite-based filter paper as well as preparation method and application thereof

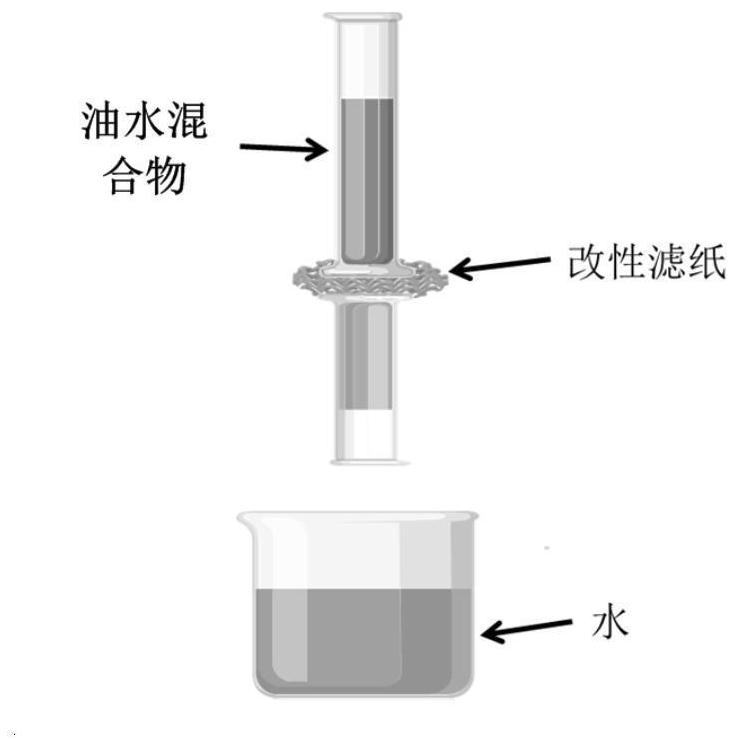

A technology of diatomite and filter paper, applied in filter paper, separation method, chemical instrument and method, etc., can solve the problems of difficult biodegradation, complicated production process, high cost of raw materials, and achieve low cost, simple operation and high separation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a kind of preparation method of diatomite-based filter paper, comprising the following steps:

[0030] A) diatomite is mixed with an organic solvent, and then reacted with a silane coupling agent to obtain modified diatomite;

[0031] B) mixing the modified diatomite, the paper material and the aqueous solution of the crosslinking agent, stirring and reacting to obtain the modified pulp;

[0032] C) After the modified pulp is filtered by suction, it is dried to obtain a diatomite-based filter paper.

[0033] In the present invention, the diatomite and the organic solvent are firstly mixed. In some embodiments of the present invention, the organic solvent is selected from toluene or xylene.

[0034] In some embodiments of the present invention, the mass ratio of the diatomite to the organic solvent is 1:2-10. In some embodiments, the mass ratio of the diatomaceous earth to the organic solvent is 1:5.

[0035] In some embodiments of the present ...

Embodiment 1

[0064] Under the protection of nitrogen, 10g of diatomaceous earth and 50g of toluene were added to the reactor, the temperature was raised to 60°C, and then 5,6-epoxyhexyltriethoxysilane was added dropwise to the reactor, and the time of dropping was controlled After 30 min, after the dropwise addition, react at 60° C. for 8 h. After the reaction, filter and dry to obtain 9.3 g of modified diatomite particles.

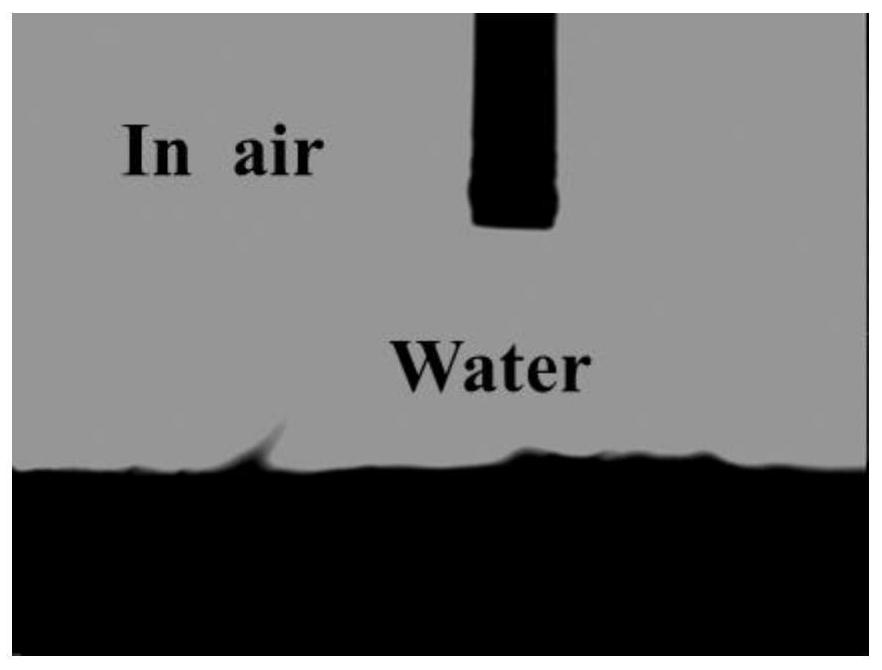

[0065] The obtained modified diatomite particles were subjected to a contact angle test, and the specific test method was as follows: firstly, the modified diatomite was pressed into a tablet, and then 2 μL of water was dropped on the modified diatomite tablet, and the contact angle was measured by a contact angle tester. The contact angle test was carried out, and the test results were as follows: figure 1 shown. figure 1 It is the water contact angle test chart of the modified diatomite particles in Example 1 of the present invention. Tests show that the water co...

Embodiment 2

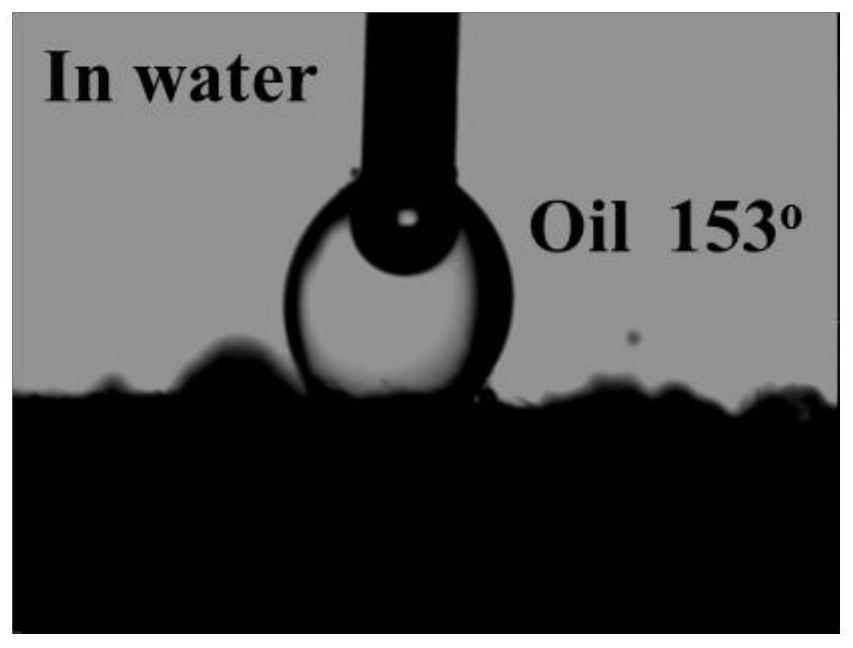

[0067] At room temperature, 0.5 g of the modified diatomite particles obtained in Example 1 and 1 g of recycled paper were added to 30 g of an aqueous solution of glutaraldehyde with a mass concentration of 10%, and stirred and reacted at 40° C. for 10 h to obtain uniform modified pulp. The reacted pulp was poured into a funnel to form a film directly through vacuum filtration (the vacuum degree of the vacuum filtration is 0.08 MPa), and dried to obtain a diatomite-based filter paper. The contact angle test results are as follows figure 2 shown. figure 2 It is the dichloromethane contact angle test chart of the diatomite-based filter paper in Example 2 of the present invention under water. The test results show that the diatomite-based filter paper has a dichloromethane contact angle of 153° under water, and has underwater super-oleophobic properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com