CNC (computer numerical control) machining center

A machining center and mounting plate technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve problems such as inability to complete parts, unreliable support of support points, and reliable clamping, etc., so as to facilitate replacement and save Processing process to ensure the effect of stable support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

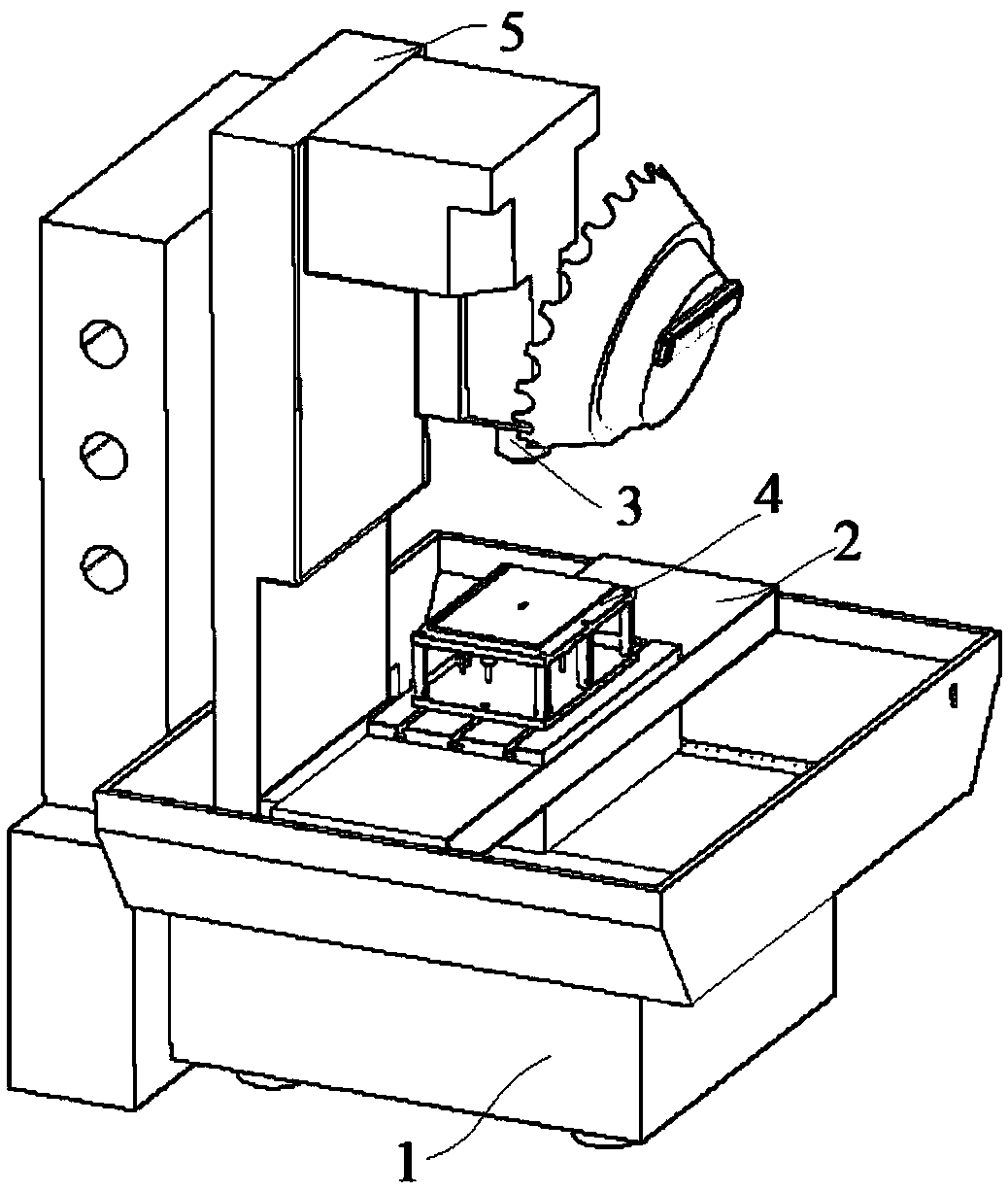

[0038] Embodiment 1: A kind of CNC machining center, including machine base 1, base plate 2, main shaft 3 and clamping jig 4, described base plate 2 is fixed on the machine base 1, and clamping jig 4 is installed on this base plate 2, so The main shaft 3 is installed on the base 1 through a mounting plate 5;

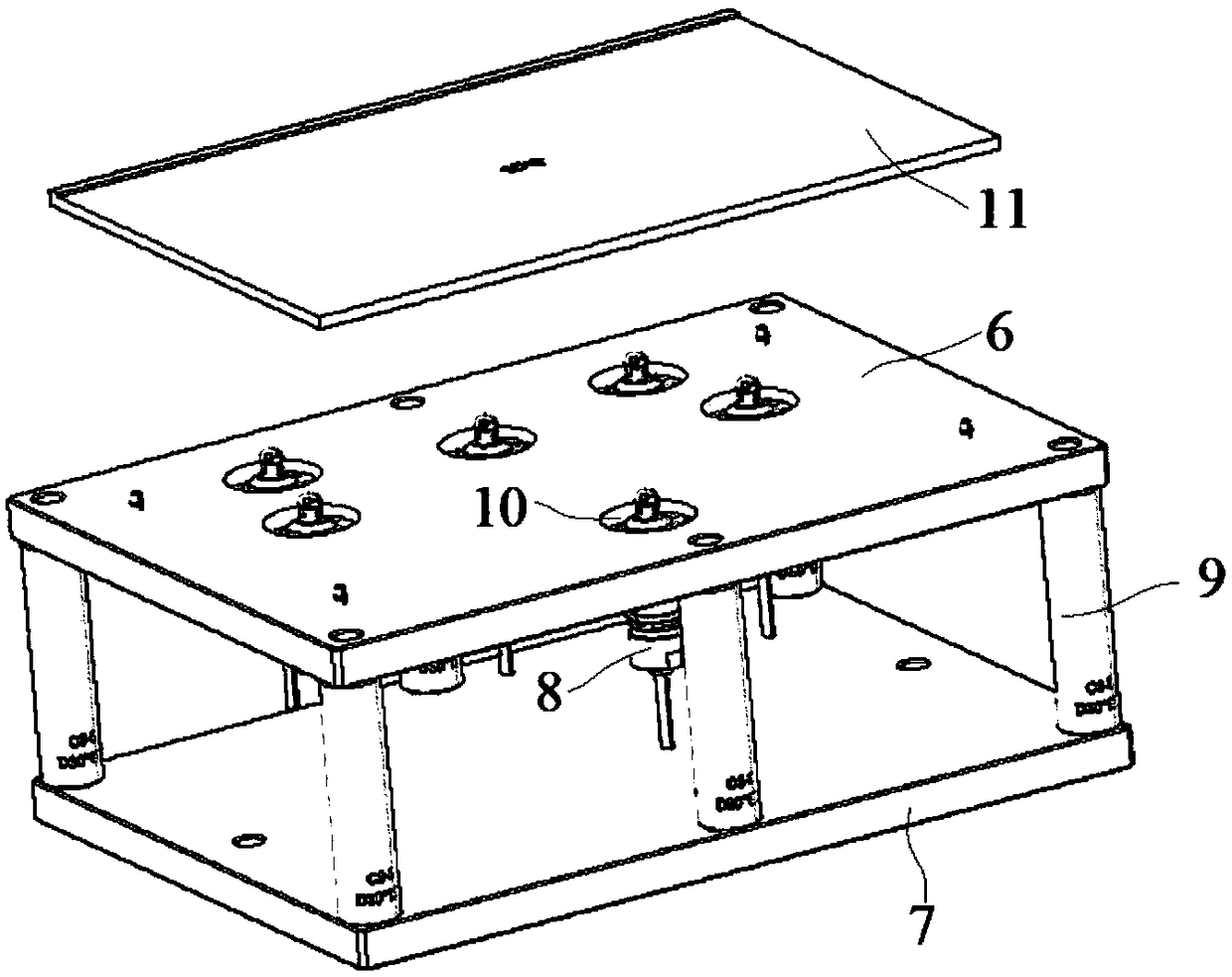

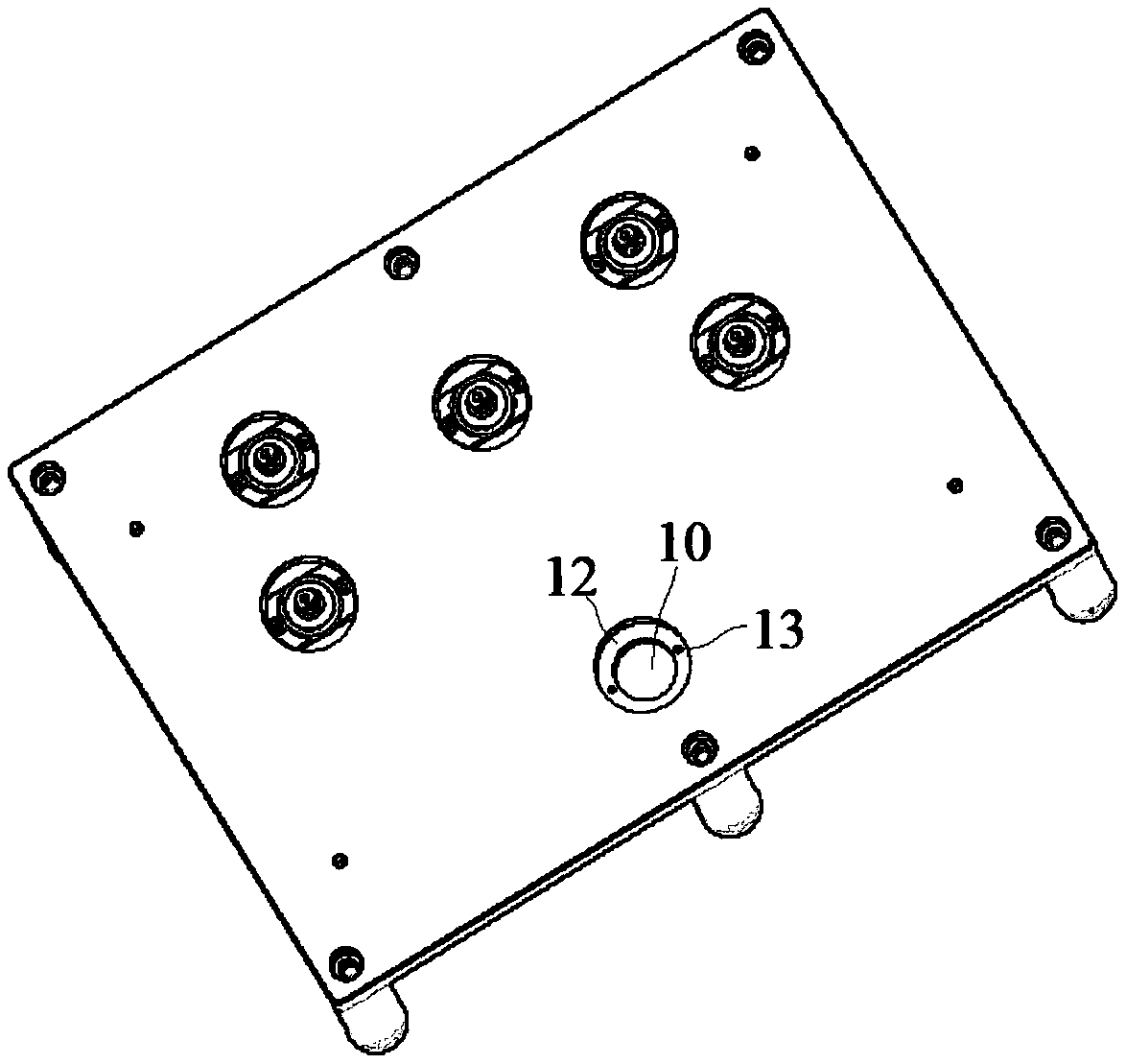

[0039] The clamping fixture 4 includes a first mounting plate 6, a second mounting plate 7 and several support heads 8 arranged in parallel, and the first mounting plate 6 and the second mounting plate 7 are connected by several support columns 9, the A plurality of through holes 10 are provided on the first mounting plate 6, and the upper ends of the support heads 8 protrude from the through holes 10 respectively and are installed and connected with the first mounting plate 6. A workpiece 11 is placed on the top of the first mounting plate 6 and connected with the first mounting plate 6. The support head 8 is contacted and connected;

[0040] The support head 8 include...

Embodiment 2

[0048] Embodiment 2: A kind of CNC machining center, including machine base 1, base plate 2, main shaft 3 and clamping jig 4, described base plate 2 is fixed on the machine base 1, and clamping jig 4 is installed on this base plate 2, so The main shaft 3 is installed on the base 1 through a mounting plate 5;

[0049] The clamping fixture 4 includes a first mounting plate 6, a second mounting plate 7 and several support heads 8 arranged in parallel, and the first mounting plate 6 and the second mounting plate 7 are connected by several support columns 9, the A plurality of through holes 10 are provided on the first mounting plate 6, and the upper ends of the support heads 8 protrude from the through holes 10 respectively and are installed and connected with the first mounting plate 6. A workpiece 11 is placed on the top of the first mounting plate 6 and connected with the first mounting plate 6. The support head 8 is contacted and connected;

[0050] The support head 8 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com