Foam extrusion vehicle and achieving method thereof

A foam, extrusion shaft technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of large volume, high cost, complex structure, etc., to solve a large number of accumulations, reduce energy consumption, and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

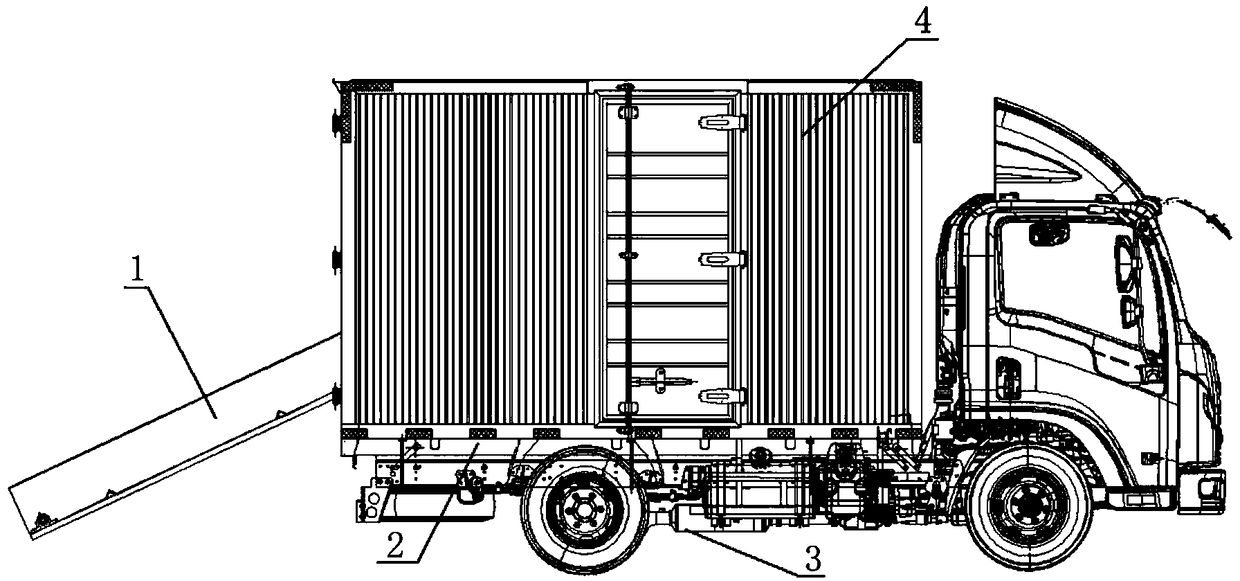

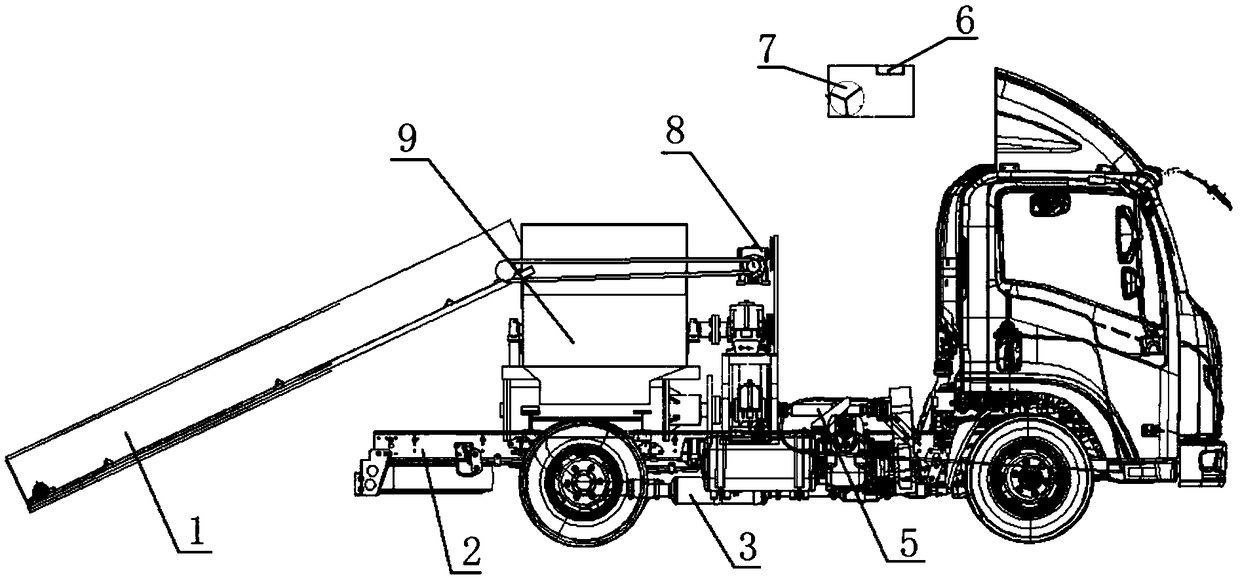

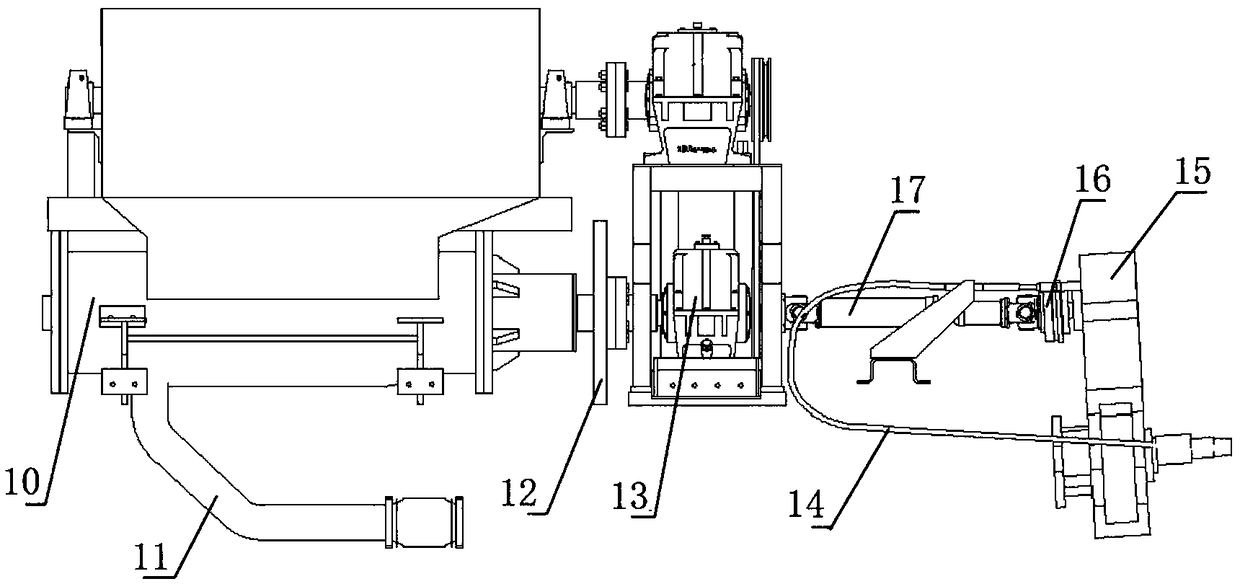

[0029] Such as Figure 1-4 As shown, the foam squeezing vehicle disclosed by the present invention and its realization method include a motor vehicle with a special chassis 2 and a fuel engine. The special chassis is equipped with a foam processing device 9 and a foam processing device. 9 connected to the power output device 5, the power output device 5 is connected to the fuel engine; the foam processing device 9 includes a conveyor belt 1 for inputting waste foam from the outside, and one end of the conveyor belt 1 is connected to provide transportation A powered worm gear reducer 8, a foam squeezing device 10 arranged below the delivery port of the conveyor belt 1, a waste heat utilization device 11 connected to the foam squeezing device 10, connected to the rotation of the foam squeezing device 10 The flywheel 12 on the shaft has one end connected to the rotating shaft of the foam squeezing device 10 and the other end of the reduction unit 13 connected to the power output d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com