Anti-corrosion structure and method of pipeline of in humid environment

A wet environment, pipeline technology, applied in the direction of pipeline anti-corrosion/rust protection, pipeline protection, pipeline laying and maintenance, etc., can solve the problems of electrochemical corrosion, pipeline corrosion, etc., to avoid corrosion, increase the stress area, good The effect of insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific examples.

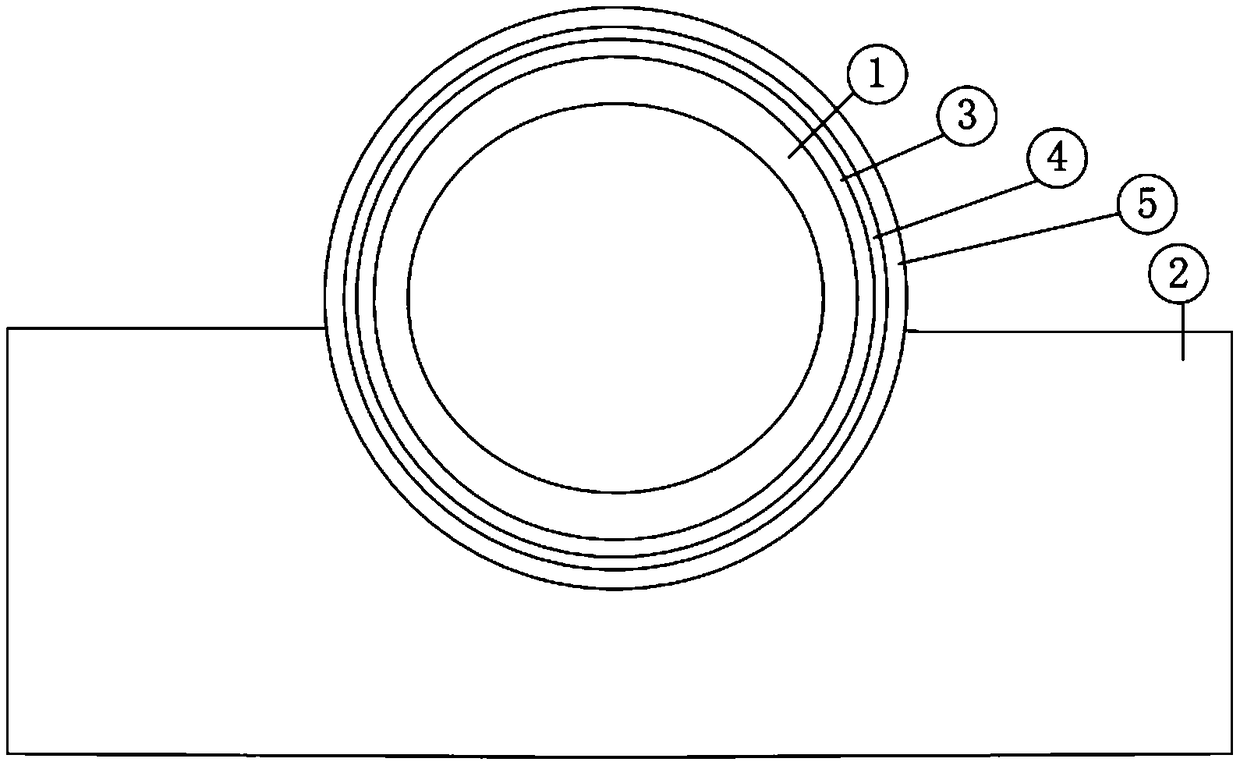

[0022] As shown in the figure, the device of the present invention comprises: pipeline (1), base (2), insulating anti-corrosion layer (3), metal mesh (4), waterproof insulating layer (5), and described base (2) is made of It is formed by pouring concrete, located under the pipeline (1), supports the pipeline (1), separates the pipeline (1) from the humid environment below, and at the same time increases the force-bearing area to avoid the settlement of the pipeline (1) by gravity; the insulating anti-corrosion layer (3) Made of natural rubber after chemical vulcanization treatment, located on the periphery of the pipe (1), close to the wall of the pipe (1) without leaving any gaps, it has good insulation, corrosion resistance, and both anti-corrosion and insulation functions; The metal mesh (4) is wound on the insulation anticorrosion layer (3),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com