Production process of flame-retardant polyurethane potting material

A production process, polyurethane technology, applied in the field of potting compound, can solve the problems of high hardness of epoxy resin potting compound, small adjustment range of potting compound hardness, slow curing time of potting compound, etc. The effect of little change in performance and low hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The production process of flame-retardant polyurethane potting compound, the production process includes the following steps:

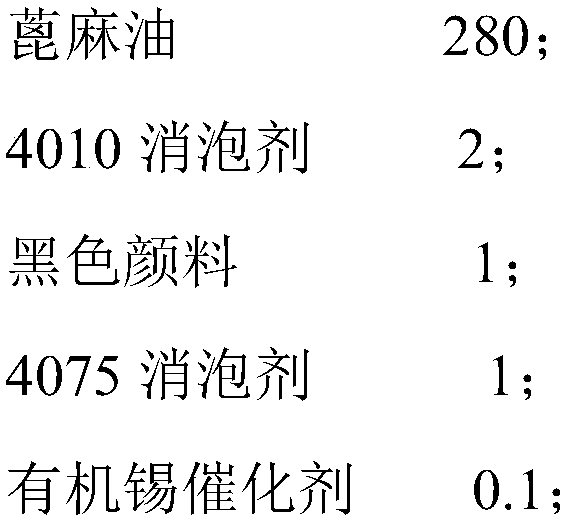

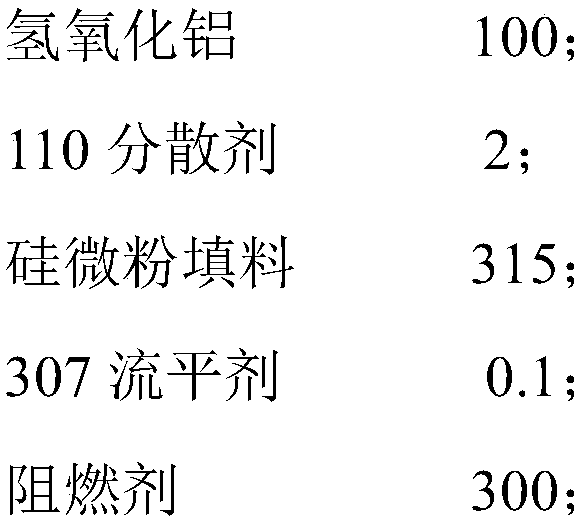

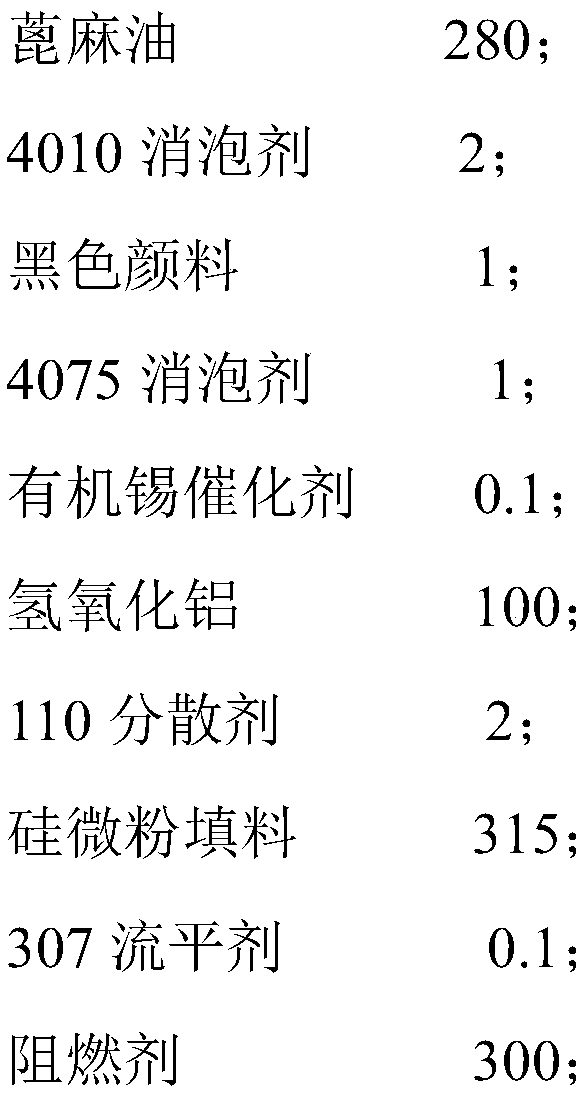

[0040] 1) Prepare raw materials according to the following parts by weight:

[0041]

[0042] 2) Feeding:

[0043] Put the raw materials into the mixing tank in the order of castor oil, 4010 defoamer, black pigment, 4075 defoamer, organotin catalyst, aluminum hydroxide, 110 dispersant, silicon micropowder filler, 307 leveling agent and flame retardant middle;

[0044] 3) Mixing:

[0045] Put the raw materials in the mixing tank, stir to make them fully mixed;

[0046] 4) Abrasives:

[0047] Pass the mixed viscous body in the mixing tank through the pipeline, and grind it to the refining tank;

[0048] 5) Refined:

[0049] 5.1) Pump the ground mixture into the refining kettle through the pipeline, heat up, start stirring and vacuumize;

[0050] 5.2) Control the refining kettle to keep the temperature at 120°C and the vacuum degree ≤ -0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com