A method for hydrocracking prolific jet fuel

A hydrocracking and hydrofining technology, which is applied in the fields of hydrotreating process, hydrocarbon oil treatment, petroleum industry, etc., can solve the problems of low saturation depth of aromatics, unqualified product quality, high content of aromatics, etc., and achieve high yield, The effect of low operation cost and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

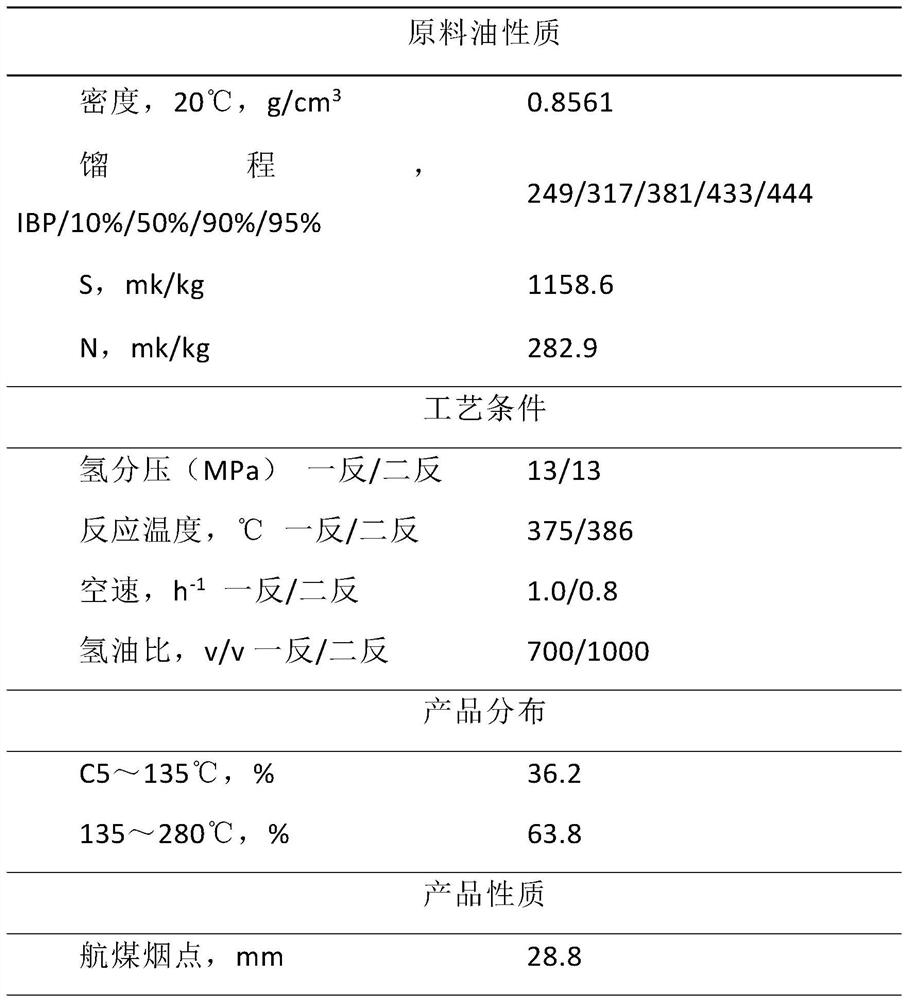

Embodiment 1

[0031] A mixed raw material of 65wt% straight-run diesel oil, 28wt% vacuum gas oil and 7wt% coker gas oil is used.

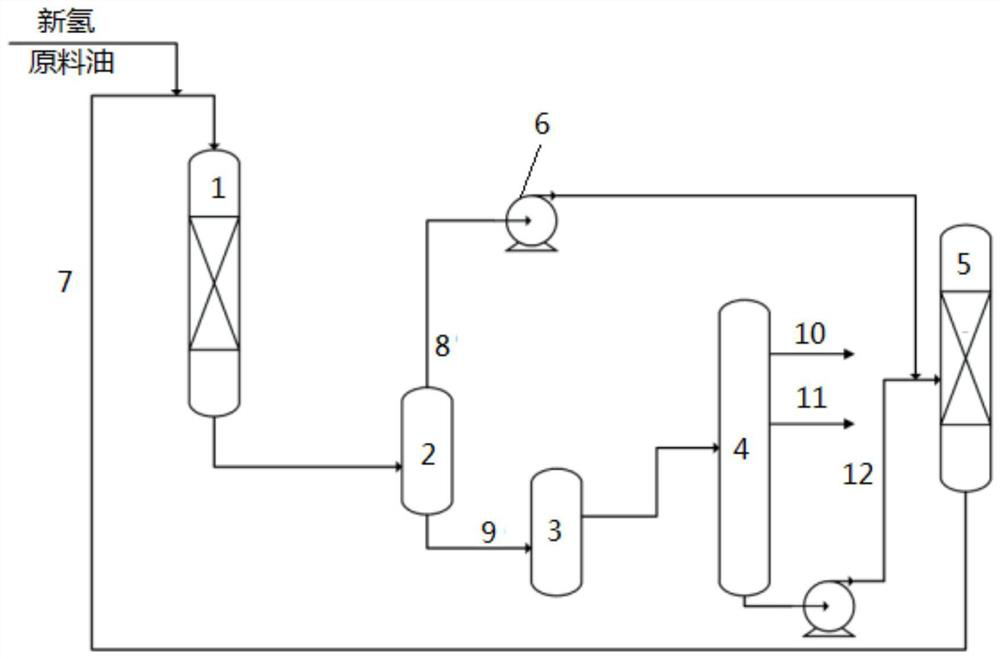

[0032] S1 First, the raw oil and new hydrogen enter the high-pressure separator 2 after undergoing hydrotreating in the first reactor 1;

[0033] S2 Then, the liquid phase stream 9 of the high-pressure separator 2 enters the low-pressure separator 3 and the fractionating tower 4 successively, and the naphtha 10 and the jet fuel fraction 11 are cut out through the fractionating tower 4;

[0034] S3 Then, the gas phase product 8 of the high pressure separator 2 is compressed by the recycle compressor 6 and enters the second reactor 5 with the bottom material 12 of the fractionation tower 4 for hydrocracking reaction;

[0035] S4 Finally, the reaction effluent 7 of the second reactor 5 is recycled back to the first reactor 1 .

[0036] Among them, the reaction conditions of the first reactor 1 are: the pressure is 13MPa, the temperature is 375°C, and the volume sp...

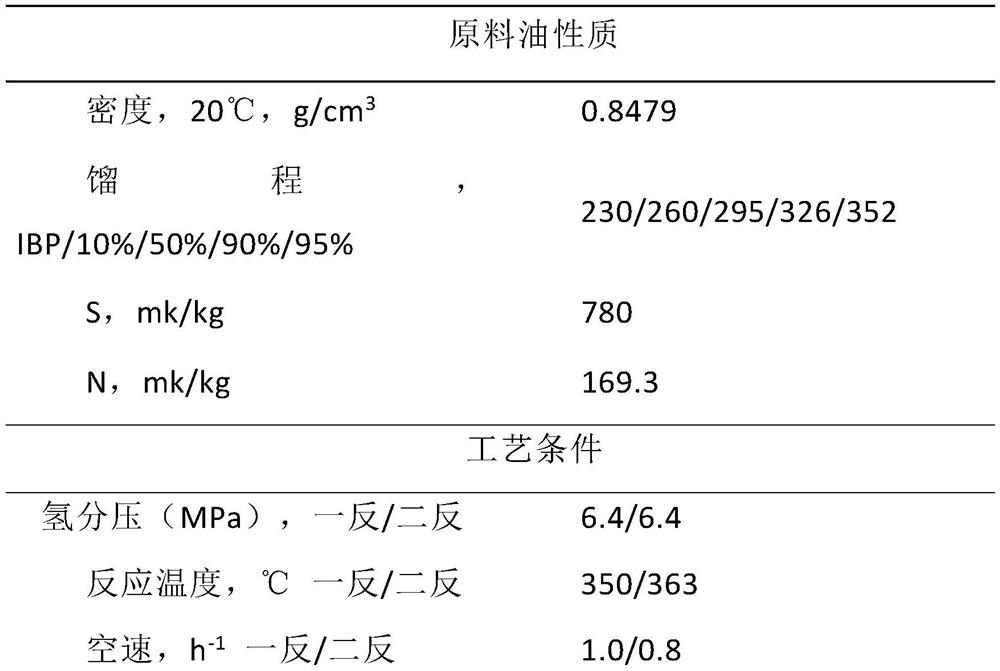

Embodiment 2

[0044] Straight-run diesel oil from atmospheric distillation unit is used as raw material, and its distillation range is 230-352°C.

[0045] S1 First, the raw oil and new hydrogen enter the high-pressure separator 2 after undergoing hydrotreating in the first reactor 1;

[0046] S2 Then, the liquid phase stream 9 of the high-pressure separator 2 enters the low-pressure separator 3 and the fractionating tower 4 successively, and the naphtha 10 and the jet fuel fraction 11 are cut out through the fractionating tower 4;

[0047] S3 Then, the gas phase product 8 of the high pressure separator 2 is compressed by the recycle compressor 6 and enters the second reactor 5 with the bottom material 12 of the fractionation tower 4 for hydrocracking reaction;

[0048] S4 Finally, the reaction effluent 7 of the second reactor 5 is recycled back to the first reactor 1 .

[0049] Among them, the reaction conditions of the first reactor 1 are: the pressure is 6.4MPa, the temperature is 350°C,...

Embodiment 3

[0058] A mixed raw material of 50wt% straight-run diesel oil, 25wt% vacuum gas oil and 15wt% coker gas oil is used.

[0059] S1 First, the raw oil and new hydrogen enter the high-pressure separator 2 after undergoing hydrotreating in the first reactor 1;

[0060] S2 Then, the liquid phase stream 9 of the high-pressure separator 2 enters the low-pressure separator 3 and the fractionating tower 4 successively, and the naphtha 10 and the jet fuel fraction 11 are cut out through the fractionating tower 4;

[0061] S3 Then, the gas phase product 8 of the high pressure separator 2 is compressed by the recycle compressor 6 and enters the second reactor 5 with the bottom material 12 of the fractionation tower 4 for hydrocracking reaction;

[0062] S4 Finally, the reaction effluent 7 of the second reactor 5 is recycled back to the first reactor 1 .

[0063] Among them, the reaction conditions of the first reactor 1 are: the pressure is 10MPa, the temperature is 375°C, and the volume s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com