A kind of catalytic cracking method and catalytic cracking inert carrier aid

A catalytic cracking, inert carrier technology, applied in chemical instruments and methods, physical/chemical process catalysts, hydrocarbon oil cracking, etc., can solve the problems of unfavorable catalytic cracking reaction, increase coke and dry gas, etc., to optimize product distribution, reduce The effect of oil specific coke and olefin product yield improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

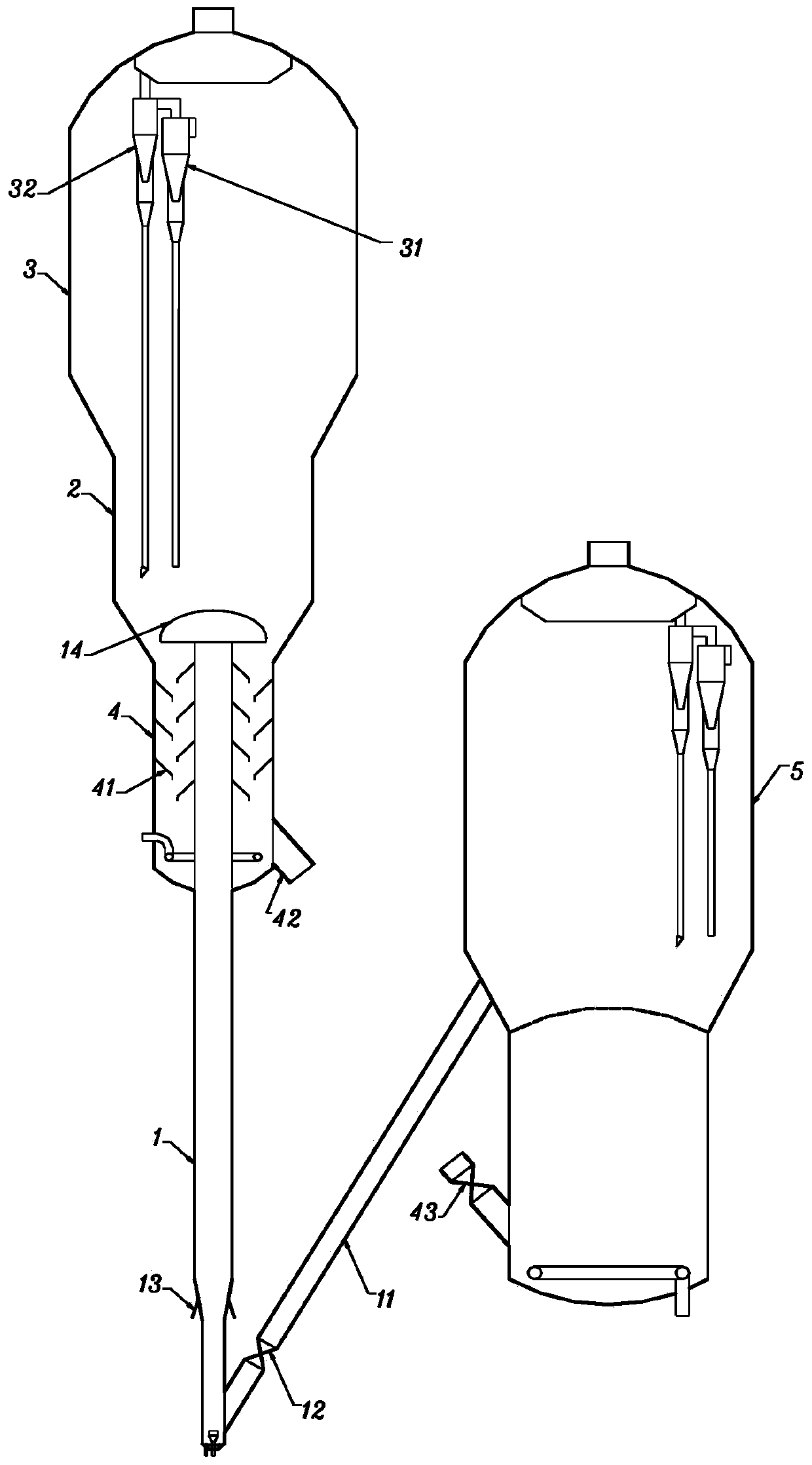

Image

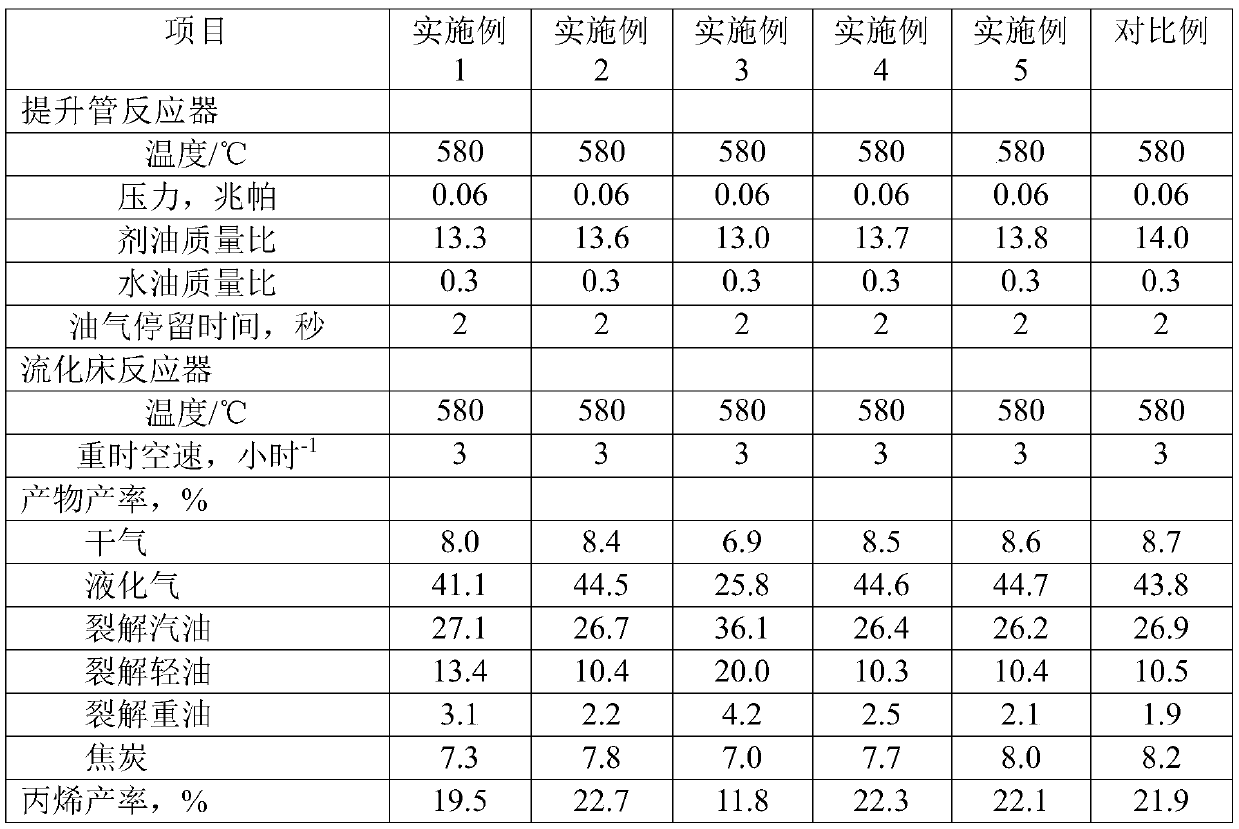

Examples

preparation example Construction

[0052] In the case of satisfying the aforementioned micro-reactive conditions, the present invention has no particular limitation on the composition of the inert carrier auxiliary particle. According to a specific embodiment of the present invention, on a dry basis and based on the total mass of the inert carrier auxiliary particles, the inert carrier auxiliary particles can include 60-100% by mass of silicon dioxide, 0-40% by mass % of titanium dioxide and 0-30% by mass of alumina, preferably including 60-80% by mass of silicon dioxide and 20-40% by mass of titanium dioxide. It should be noted that, unless otherwise specified, the silicon dioxide, titanium dioxide and aluminum oxide mentioned herein all refer to the chemical composition of the inert carrier auxiliary particles, and those skilled in the art can use different catalyst raw materials to prepare the inert carrier Auxiliary particles, the catalyst raw material can include but not limited to silicon dioxide, clay, s...

preparation Embodiment 1

[0079] Silica sol and titanium dioxide powder were mixed in a weight ratio of 3:1, beaten, and then spray-dried. The obtained spray microspheres were dried and then calcined at 900°C to obtain inert carrier additive 1. The properties of the inert carrier auxiliary agent 1 are shown in Table 1. The chemical composition of the inert carrier auxiliary agent 1 is: 60% by mass of silicon dioxide and 40% by mass of titanium dioxide.

preparation Embodiment 2

[0081] Silica sol and titanium dioxide powder were mixed at a weight ratio of 8:1, beaten, and then spray-dried. The obtained spray microspheres were dried and then calcined at 900°C to obtain inert carrier additive 2. The properties of the inert carrier auxiliary agent 2 are shown in Table 2. The chemical composition of the inert carrier auxiliary agent 2 is: 80 mass % silicon dioxide and 20 mass % titanium dioxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com