Multifunctional moving dust collecting cover

A dust hood, multi-functional technology, applied in the direction of removing smoke and dust, load hanging components, chemical instruments and methods, etc., can solve problems such as poor coordination and poor coordination, and achieve optimization of process flow, reduction of dust pollution, and improvement of work. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

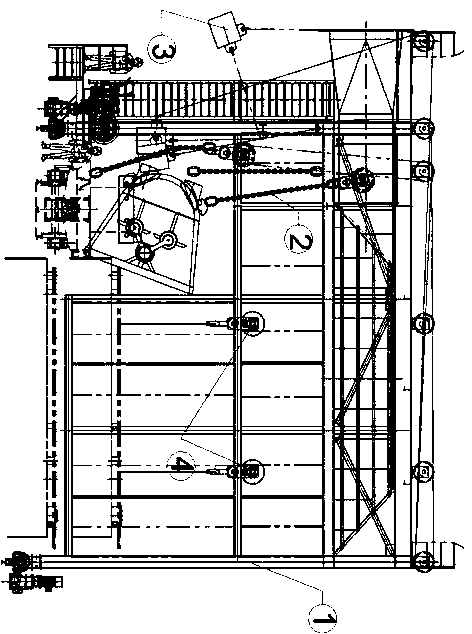

[0033] figure 1 Shown, the present invention is made up of mobile dust collecting device 1, tipping device 2, pounding pot device 3, hanging cover device 4. The tipping device 2, the pot pounding device 3 and the hanging cover device 4 are arranged on the mobile dust collecting device 1.

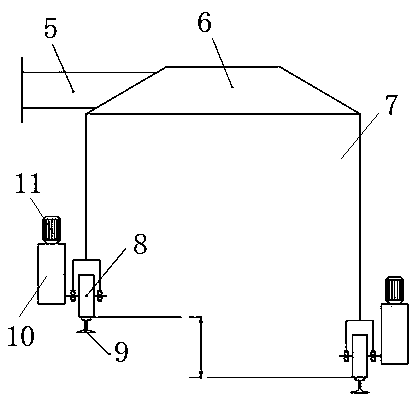

[0034] figure 2 As shown, the mobile dust collection device 1 is composed of a dust collection cover body 7, a top cover 6, a track 9, a wheel set 8, a frequency conversion drive motor 11, and a reducer 10. A top cover is arranged on the dust collection cover body, and a row Trachea 5; the track is arranged above the hot stew pool, the wheel group is arranged on the track, the frequency conversion drive motor is connected to the speed reducer, the output shaft of the speed reducer is connected to the wheel axle, the wheel axle is installed with the wheel, and the wheel axle is installed at the bottom of the dust collection frame body. The difference in height of the tracks is 1 meter. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com