Steel for automobile b-pillar reinforcement plate and preparation method thereof

A technology for reinforcing plates and B-pillars, applied in manufacturing tools, heat treatment equipment, furnaces, etc., can solve the problems of high manufacturing costs of parts and large investment in production lines, and achieve the effects of low cost, stable production process, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0062] A method for preparing steel for an automobile B-pillar reinforcement plate, comprising the following steps:

[0063] Step 1, vacuum furnace smelting:

[0064] According to the chemical composition of the steel for the automobile B-pillar reinforcement plate, weigh the raw materials, smelt them in a 200kg vacuum furnace to obtain ingots, the chemical composition of the steel for the automobile B-pillar reinforcement plate is shown in Table 1, and the balance is Fe and unavoidable impurities;

[0065] Step 2: Ingot Heating

[0066] Heating the ingot to obtain a heated ingot; wherein, the heating temperature is 1200°C, and the holding time is 120-150min;

[0067] Step 3, Rough Rolling

[0068] The heated ingot is subjected to 7 passes of rough rolling. The starting temperature of rough rolling and the total reduction ratio of rough rolling are shown in Table 2 to obtain a rough rolling intermediate billet with a thickness of 29.5-34.5mm;

[0069] Step 4, finishing rol...

Embodiment 2

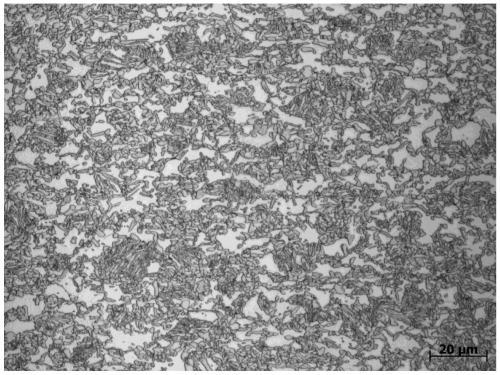

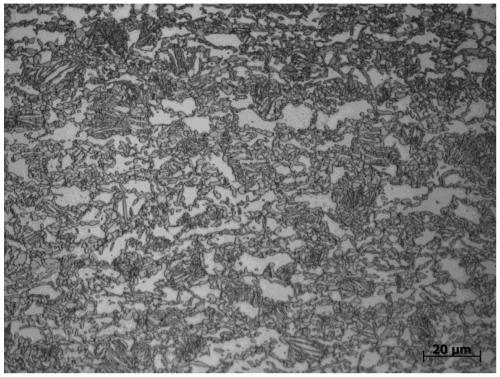

[0085] The metallographic structure of the steel for the automobile B-pillar reinforcement plate that embodiment 2 obtains is as follows: figure 1 Shown, the metallographic structure of the steel for the automobile B-pillar reinforcing plate that embodiment 3 obtains is as follows figure 2 It can be seen from the figure that the prepared steel for automobile B-pillar reinforcement mainly contains ferrite, bainite and retained austenite. It needs to be further explained that: the ferrite structure includes two forms of α-ferrite and δ-ferrite, which endow the steel with excellent strength and elongation properties; the forms of retained austenite mainly include massive residual austenite and thin film The massive retained austenite is prone to phase transformation during the stretching process, which endows the steel with excellent elongation properties, while the film-like retained austenite can hinder the propagation of cracks, which can greatly improve the strength and plas...

Embodiment 1

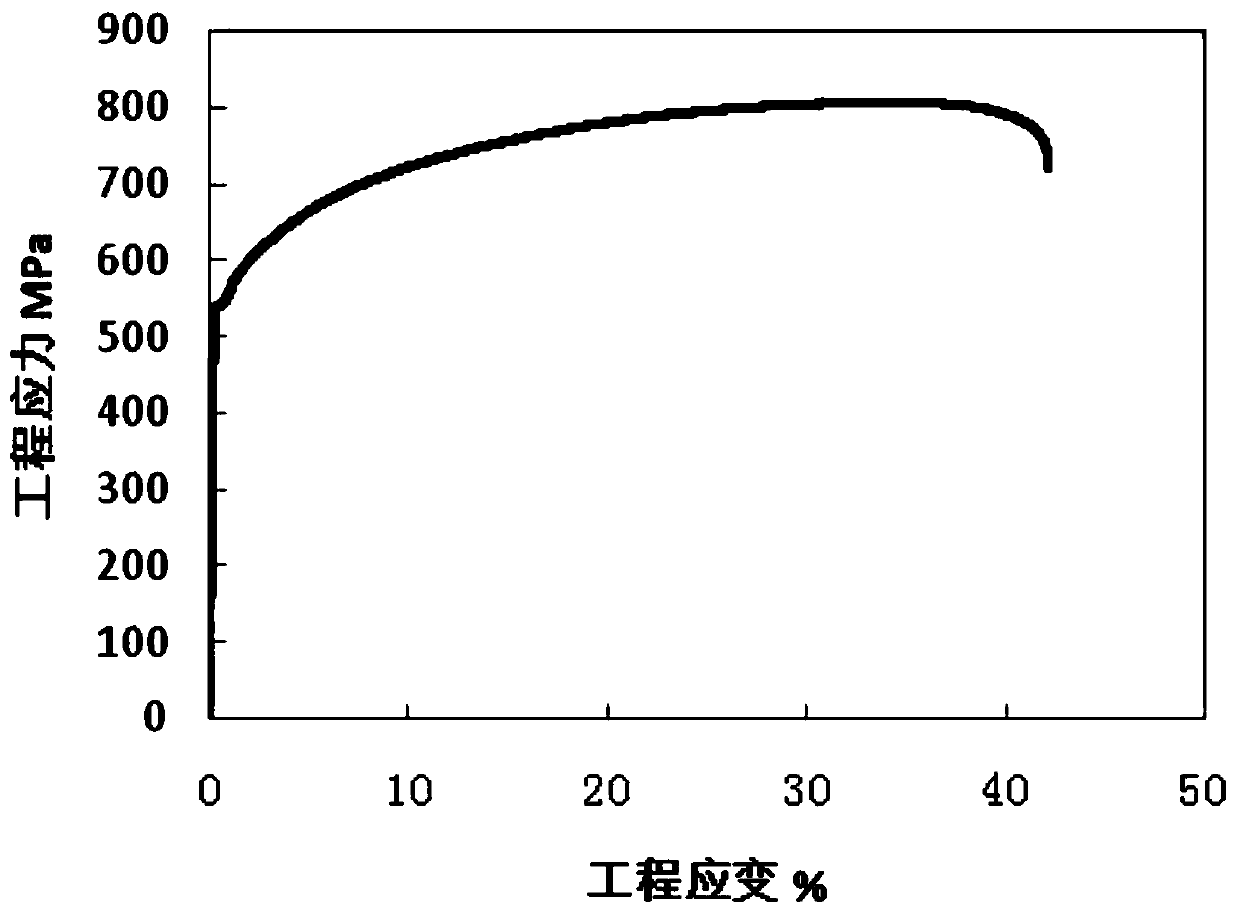

[0086] The stress-strain curve of the steel for the automobile B-pillar reinforcement plate that embodiment 1 obtains is shown in image 3 ,From image 3 Among them, the yield strength of the steel for the B-pillar reinforcement plate of Example 1 is 522MPa, the tensile strength is 806MPa, the elongation is 42%, and the strength-plastic product is 33.852GPa·%.

[0087] It can be seen from the above examples that the tensile strength of the steel for B-pillar reinforcement plates of automobiles prepared by adopting the composition design, rolling and continuous annealing process of the present invention is 800-850 MPa, the elongation is 38-44%, and the strong-plastic product is 30-35 GPa. %, meeting the requirements of high strength, high plasticity and low cost of the B-pillar reinforcement plate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com