Adjusting turnover type kitchen and bathroom flashing construction technology and flashing mould thereof

A construction technique and technology for kitchen and bathroom, which are applied in the field of adjusting the construction technique of revolving kitchen and bathroom counter-sills and their counter-sill moulds, can solve the waste of square wood and wooden formwork resources, the difficulty of formwork erection and installation, and the difficult construction quality. Guarantee and other issues, to achieve the construction efficiency of repeated turnover, meet the needs of construction quality and construction period, and achieve good construction results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

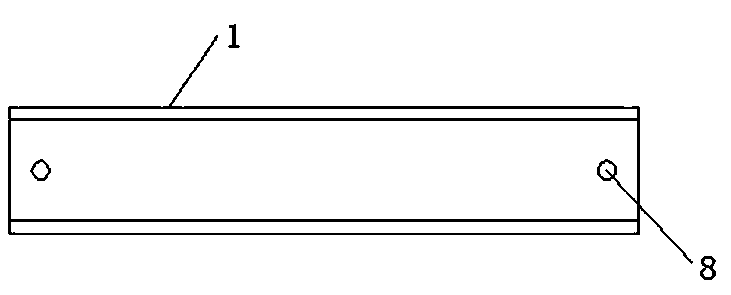

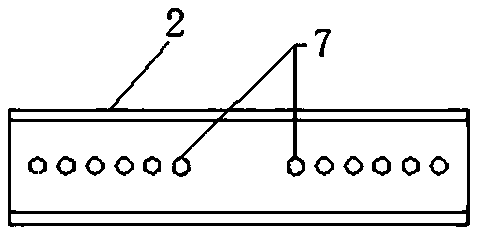

Embodiment 1

[0047] as attached Figure 1~2 As shown, firstly, the original construction design drawings of multiple projects or the actual construction site are combined to conduct comprehensive analysis and calculation of the pouring foundation of the reverse sill, and draw the design drawing of the mold according to the data and conclusions obtained from the calculation; secondly, according to the steps A The prepared construction drawing is processed to make the pouring formwork, and the plate with a thickness of not less than 0.2cm is selected to make the main formwork 1 with a length of 20cm and a height of 10cm, and the adjustment formwork 2 with a length of 30cm and a height of 10~30cm The connectors 3 are provided with connection holes 8 at both ends of the main formwork 1, adjustment holes 7 are provided at the middle and upper part of the adjustment formwork 2, and number A mounting hole 6 connecting the formwork bracket 5 is provided with at least one reinforcing rib on the out...

Embodiment 2

[0051] as attached Figure 1~2 As shown, firstly, the original construction design drawings of multiple projects or the actual construction site are combined to conduct comprehensive analysis and calculation of the pouring foundation of the reverse sill, and draw the design drawing of the mold according to the data and conclusions obtained from the calculation; secondly, according to the steps The construction drawing obtained in A is processed to make the pouring formwork, and the plates with a thickness of not less than 0.2cm are selected to make the main formwork 1 and the adjustment formwork 2 with a length of 60cm and a height of 20cm, and a connection with a length of 70cm and a height of 20cm. Part 3, connection holes 8 are provided at both ends of the main formwork 1, adjustment holes 7 are provided at the middle and upper part of the adjustment formwork 2, and several connection holes are respectively arranged on the upper part or the top of the main formwork 1 and the...

Embodiment 3

[0055] as attached Figure 1~2 As shown, firstly, the original construction design drawings of multiple projects or the actual construction site are combined to conduct comprehensive analysis and calculation of the pouring foundation of the reverse sill, and draw the design drawing of the mold according to the data and conclusions obtained from the calculation; secondly, according to the steps A. The prepared construction drawing is processed to make the pouring formwork, and the plate with a thickness of not less than 0.2cm is selected to make the main formwork 1 and the adjustment formwork 2 with a length of 100cm and a height of 30cm, and make a connection with a length of 110cm and a height of 30cm. Part 3, connection holes 8 are provided at both ends of the main formwork 1, adjustment holes 7 are provided at the middle and upper part of the adjustment formwork 2, and several connection holes are respectively arranged on the upper part or the top of the main formwork 1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com