Infinite approximation automatic correction method and system based on optical axis consistency measurement

An automatic calibration and consistency technology, applied in measuring devices, optical instrument testing, testing optical performance, etc., can solve the problem of lack of high-precision automatic calibration methods, and achieve great practical value, save time, and improve calibration accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The infinite approximation automatic correction method based on optical axis consistency measurement includes the following steps: the photoelectric correction operation terminal (ie, the upper computer) remotely controls the target, and returns the target to the center of the target plane, while ensuring that the target plane is consistent with the plane of the photoelectric equipment to be corrected Parallel; adjust the pitch and azimuth of the target by pasting fluorescent strips on the side of the target. When the fluorescent strips around the target exceed the field of view of the optoelectronic equipment, the target plane is considered to be parallel to the plane of the optoelectronic equipment to be corrected. In order to facilitate later focusing, the target is fixed by a tripod, and the distance between the tripod and the photoelectric equipment is 50±5m. In this embodiment, the distance between the tripod and the photoelectric equipment to be calibrated is 50m....

Embodiment 2

[0058] Infinity approximation automatic correction system based on optical axis coincidence measurement, such as Figure 6 As shown, including target, tripod and host computer;

[0059] The tripod includes a bracket, and a power management module, an azimuth motion mechanism, a pitch motion mechanism, a motion control module and a main control module arranged on the bracket.

[0060] The power management module is used to supply power to the correction system.

[0061] The main control module communicates with the upper computer, and coordinates the operation of other modules, such as the overall control of the laser beam center positioning module, motion control module, wireless communication module, multi-spectral light source generation module and power management module; also includes wireless communication module, the main control module is connected with the upper computer through a wireless communication module.

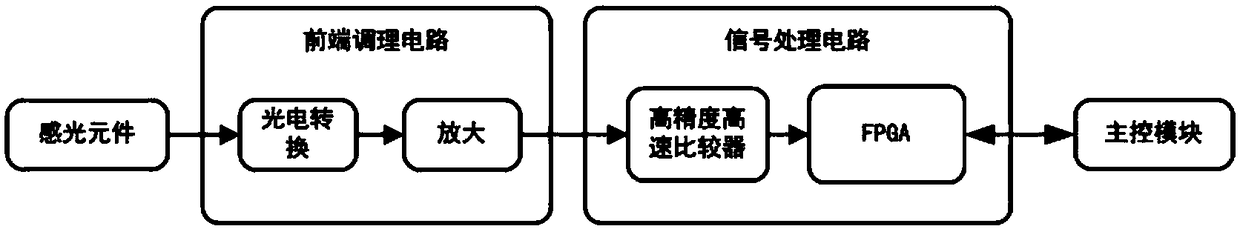

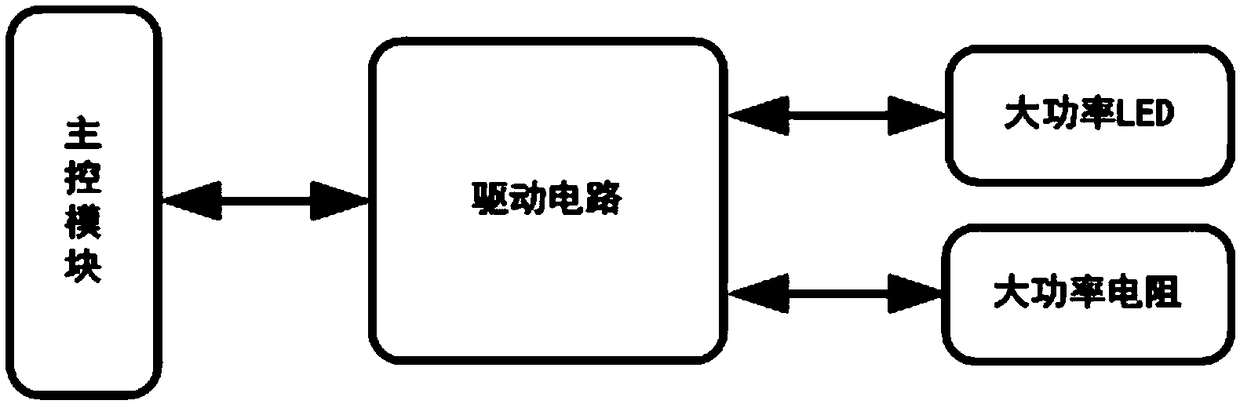

[0062] The main functions and implementation methods o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com