Array substrate, making method thereof and display panel

The technology of an array substrate and a manufacturing method is applied in the field of an array substrate, a manufacturing method thereof and a display panel, which can solve the problems of increased production cost and increased manufacturing process, and achieve the effects of reducing the production cost, reducing the process and saving the production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

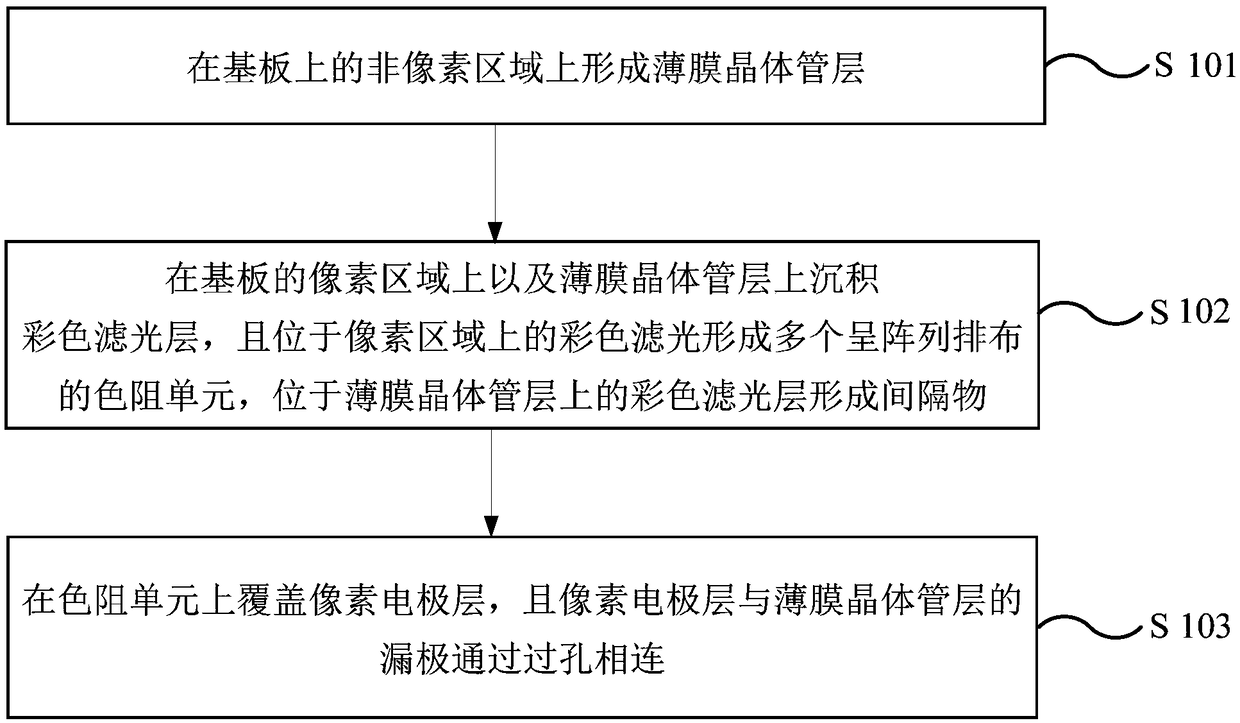

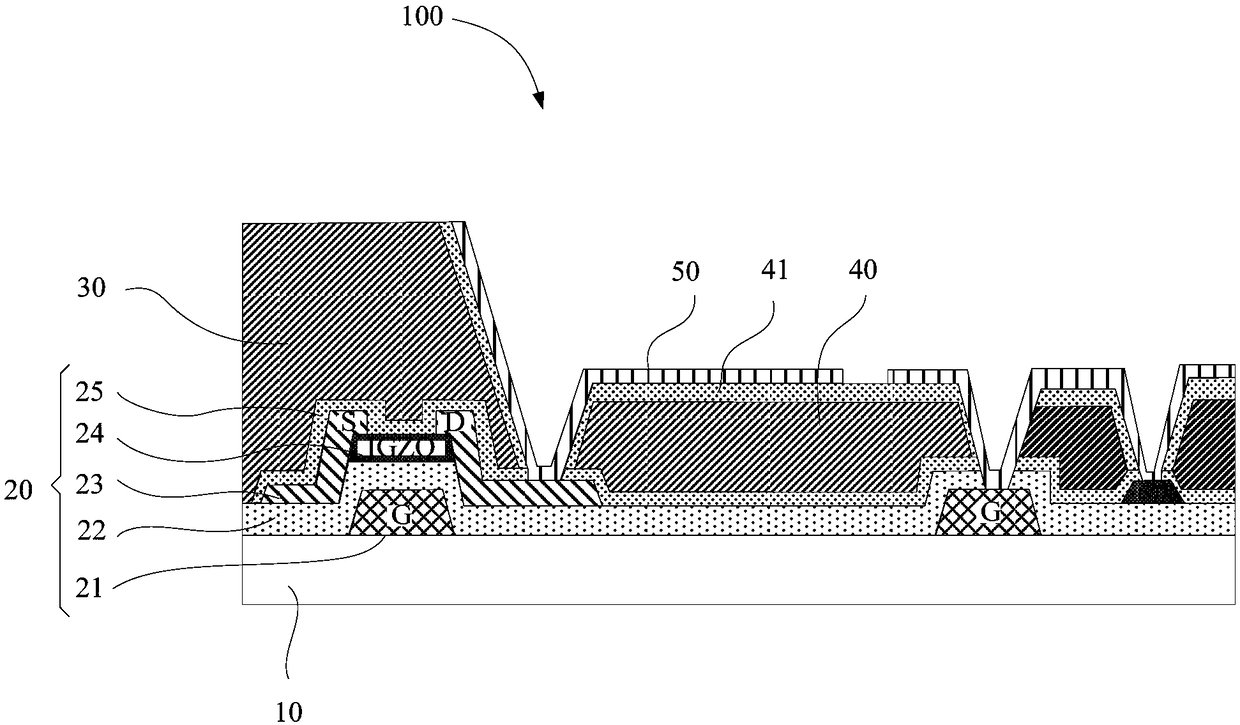

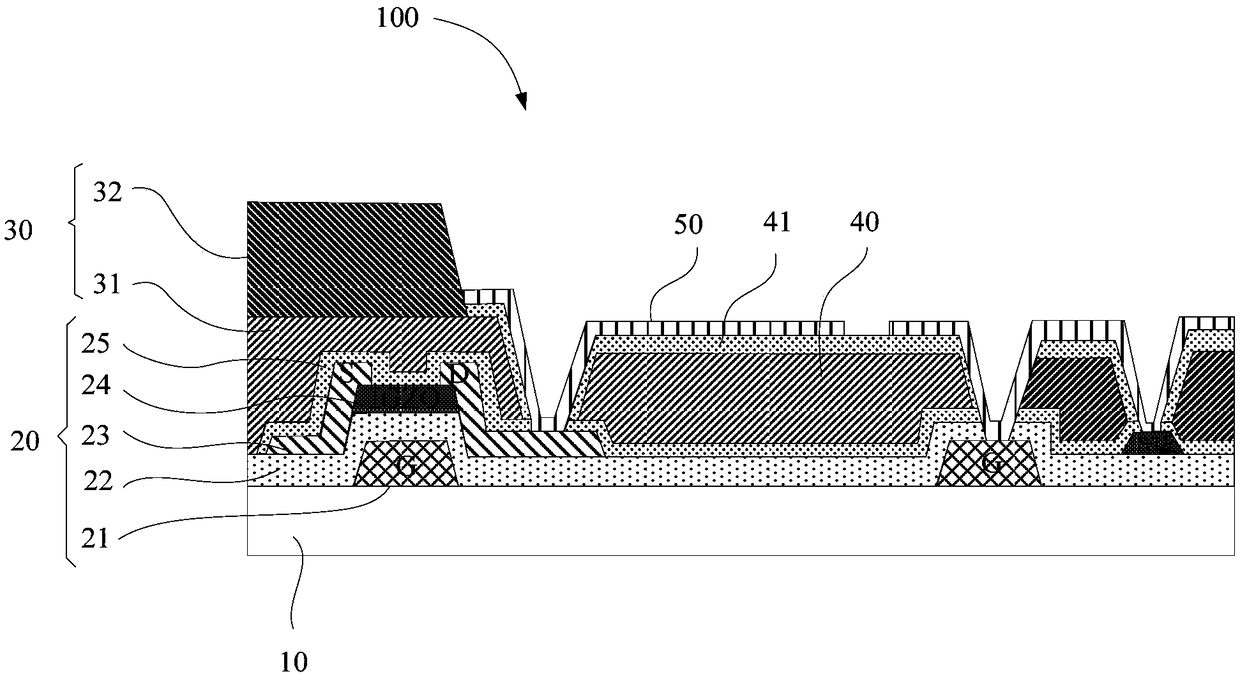

[0070] figure 1 It is a schematic flowchart of the manufacturing method of the array substrate provided by Embodiment 1 of the present invention, figure 2 A schematic structural view of the array substrate provided by the present invention, image 3 Another structural schematic diagram of the array substrate provided by the present invention, Figure 4 Another structural schematic diagram of the array substrate provided by the present invention;

[0071] This embodiment provides a method for manufacturing an array substrate, specifically an array substrate (color filter on array, COA for short) provided with a color filter, that is, a COA array substrate. In this embodiment, the array substrate used The spacer (PS) is formed simultaneously in the process of forming the color filter on the color filter, thereby avoiding setting up the PS process independently to form the PS. The number of steps in the process is reduced, thereby reducing production costs.

[0072] Wherein,...

Embodiment 2

[0117] This embodiment provides an array substrate 100, the array substrate 100 is manufactured by using the preparation method of any one of the above embodiments, see Figure 2-4 As shown, the array substrate 100 includes: a thin film transistor layer 20 disposed on the substrate 10, a plurality of color resistance units 40 arranged in an array, and a drain covering the color resistance units 40 and connected to the drain of the thin film transistor layer 20. The pixel electrode layer 50, and the spacer 30 is arranged on the thin film transistor layer 20, wherein, in this embodiment, since the PS is formed at the same time as the preparation of the color resistance unit 40, the manufacturing process of the array substrate 100 is reduced, and the Production cost, wherein, in this embodiment, since the color-resist unit 40 is located on the array substrate 100 , the array substrate 100 is specifically a COA array substrate 100 .

[0118] Wherein, in this embodiment, each color...

Embodiment 3

[0122] Figure 5 It is a schematic structural diagram of a display panel provided by Embodiment 3 of the present invention.

[0123] This embodiment provides a display panel 200, such as Figure 5 As shown, the display panel 200 includes the above-mentioned array substrate 100, the opposite substrate 60 arranged in a box with the array substrate 100, and the liquid crystal filled between the array substrate 100 and the opposite substrate 60, wherein the spacer on the array substrate 100 One end of 30 is abutted against the common electrode or black matrix on the opposite substrate 60. In the embodiment, since the color resist unit 40 is arranged on the array substrate 100, that is, the color filter layer is located on the array substrate 100, the color filter There is no need to arrange color filters on the substrate 10, so as Figure 4 As shown, the opposite substrate 60 opposite to the array substrate 100 includes a black matrix (Black Matrix, BM for short) 62 disposed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com