Rapid separation apparatus and separation method of oil-water mixture

A technology of oil-water mixture and separation device, which is applied in separation methods, filtration separation, liquid separation, etc. It can solve the problems of large storage tanks of feed liquid and extraction agent, bulky equipment in the clarification section, and occupation of enterprise working capital, etc., to reduce The storage capacity of material liquid and extractant, easy automatic operation, and the effect of ensuring stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following description illustrates specific embodiments of the invention sufficiently to enable those skilled in the art to practice and reproduce it.

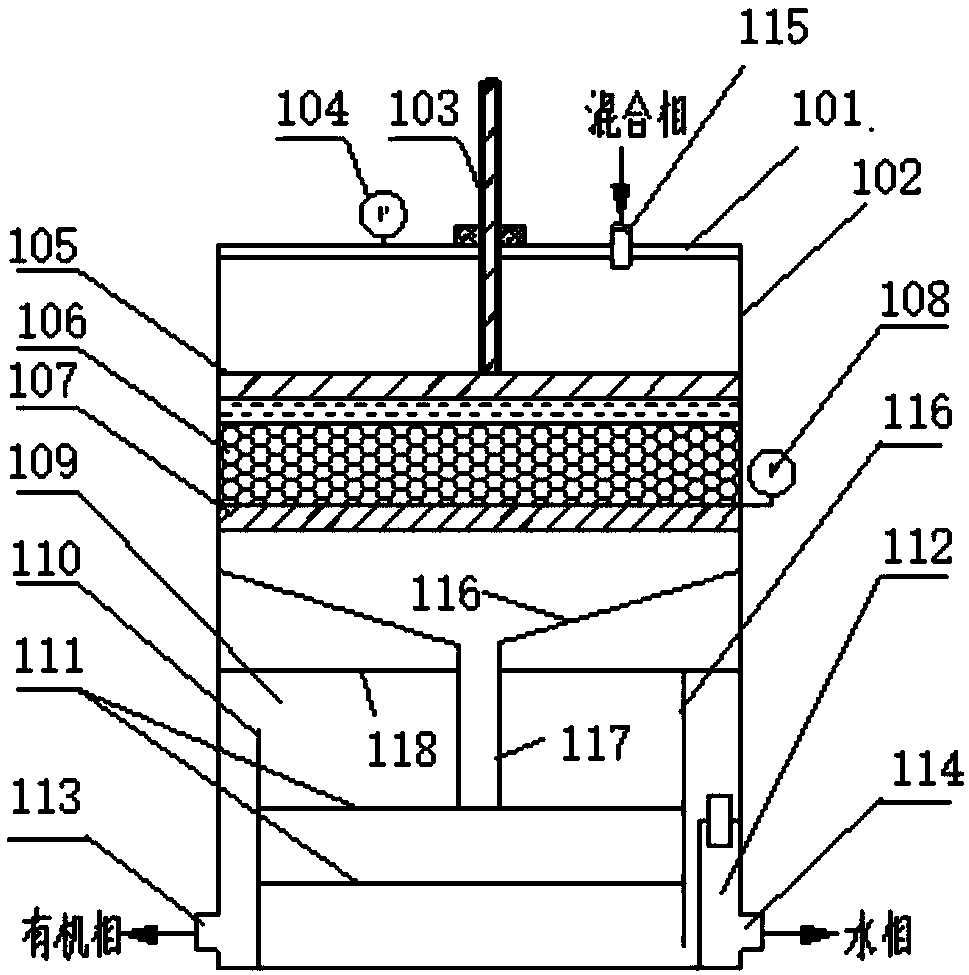

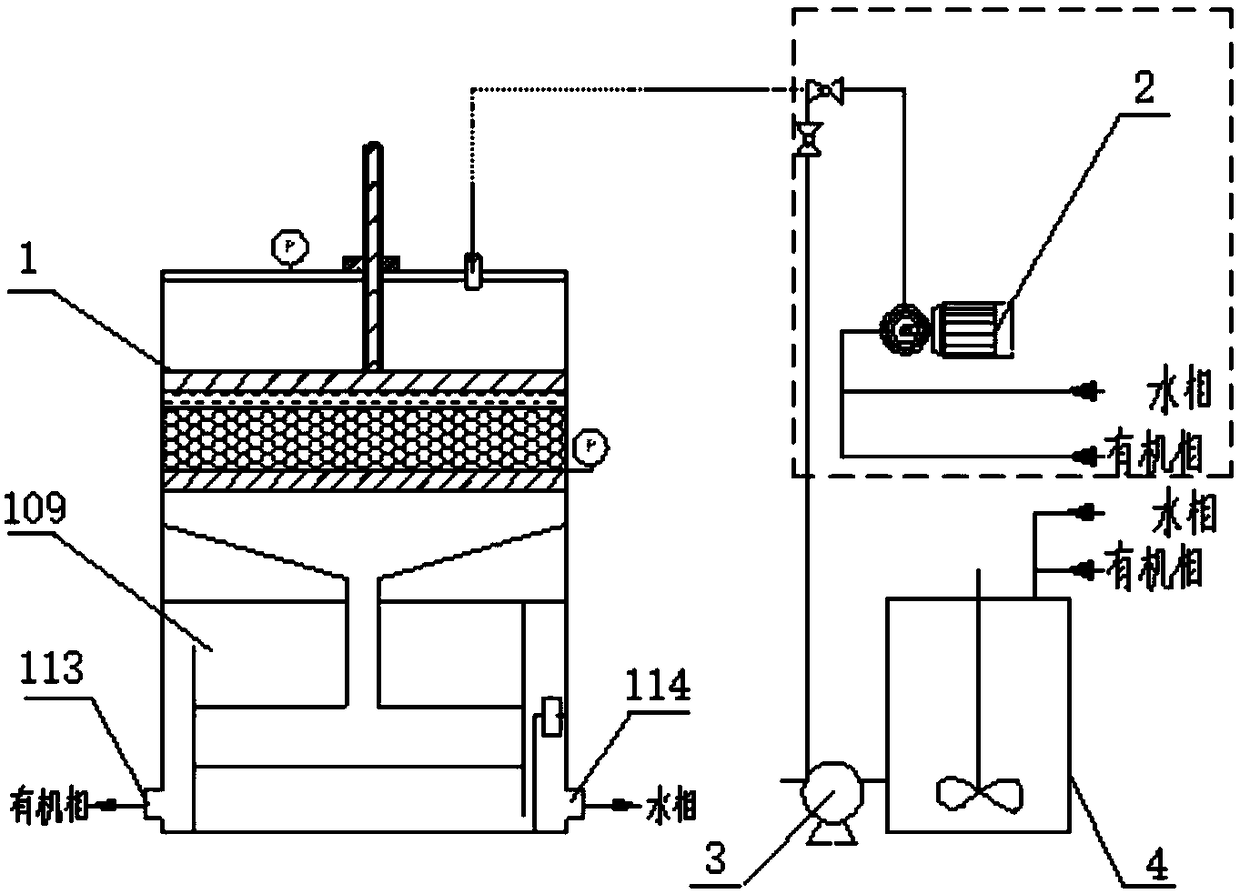

[0028] Such as figure 1 Shown is a schematic structural view of the oil-water separator 1 in the present invention.

[0029] The oil-water mixture rapid separation device includes an oil-water separator 1, which is a closed and pressure-bearing container, including: a top cover 101, a tank body 102, a pressing device 103, a pressure gauge 104, an extrusion plate 105, and a fiber layer 106 , a pressure bearing plate 107 , a pressure sensor 108 , a receiving tank 109 , an overflow plate 110 , a sieve plate 111 , and a water phase adjustment box 112 .

[0030] The top cover 101 and the tank body 102 are made of materials that can withstand 0.5MPa to 1MPa. The top cover 101 is arranged on the top of the tank body 102, and the top cover 101 and the pressing device 103 are connected by threads; the pressure sensor 108 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com