Method and system of cooperative VOC biological treatment

A biological treatment, synergistic technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of cumbersome steps to remove VOC waste gas, low VOC waste removal efficiency, etc., to achieve comprehensive removal efficiency improvement, friendly and free. The effect of secondary pollution and investment reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment provides a synergistic VOC biological treatment method, the specific operation steps are as follows:

[0024] 1) The VOC exhaust gas is treated once through polyurethane filler or PP inorganic filler, and the centrifugal fan or blower can be used to pump the VOC exhaust gas into the polyurethane filler or PP inorganic filler through positive or negative pressure. Keep spraying the polyurethane filler or the inorganic filler of PP with circulating water, so that the microorganisms in the circulating water can form a film on the surface of the polyurethane filler or the inorganic filler of PP, and inject the nutrient solution into the circulating water while spraying the circulating water , to discharge the generated waste liquid in a concentrated manner. The polyurethane filler or PP inorganic filler has light and porous characteristics and is a good carrier for microbial growth. At the same time, the circulating water can ensure the ideal humidity of the ...

Embodiment 2

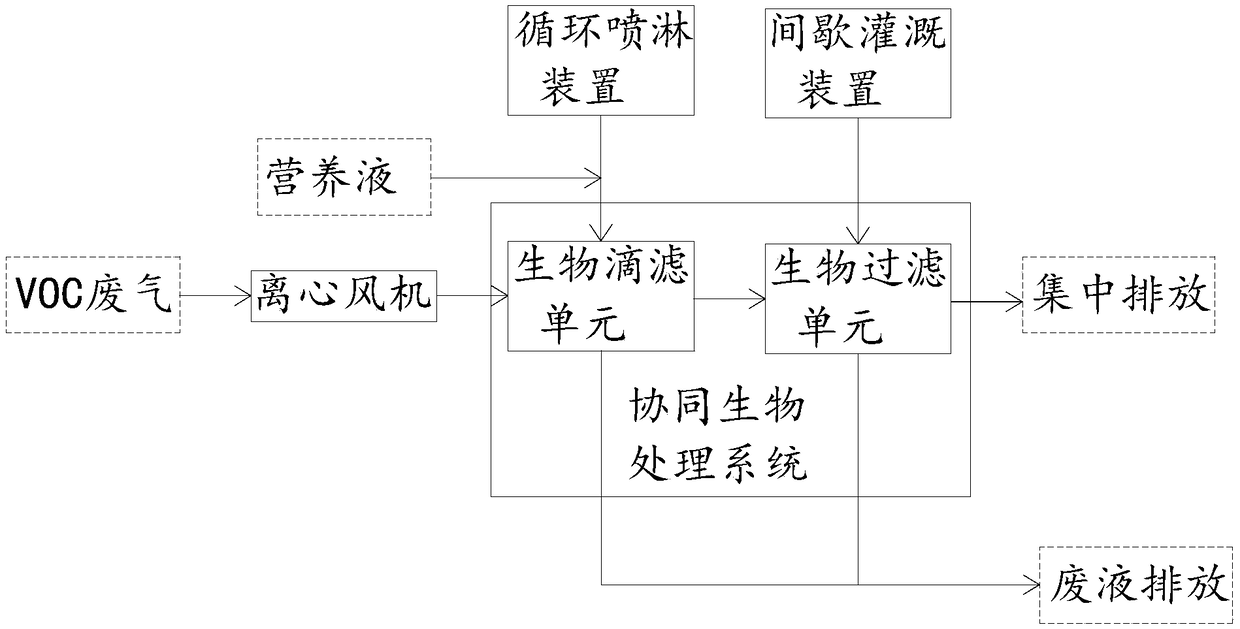

[0029] Such as figure 1 As shown, a cooperative VOC biological treatment system includes a cooperative biological treatment system, a circulating spray device and an intermittent irrigation device. The filter unit is connected with the circulating spraying device, and the biological filtering unit is connected with the intermittent irrigation device; the circulating spraying device is also connected with a nutrient solution injection device. The nutrient solution injecting device may inject the nutrient solution into the pipeline of the circulating spraying device through a pump, or inject the nutrient solution into the interior in other ways.

[0030] Specifically, the biological trickling filter unit is a biological trickling filter tower, and the biological trickling filter tower is provided with polyurethane filler or PP inorganic filler; the bottom of the biological trickling filter tower below the polyurethane filler or PP inorganic filler is provided with an anti-corros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com