Laser welding device

A technology of laser welding and pressing device, used in laser welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of low ultrasonic power, increasing the gap between the aluminum plate and the battery, affecting the strength of the weld and the overcurrent capacity, etc. The effect of overcoming the lack of energy, reducing the weight of the module and reducing the phenomenon of virtual welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the purpose of the invention, technical solution and beneficial technical effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods. It should be understood that the specific implementations described in this specification are only for explaining the present invention, not for limiting the present invention.

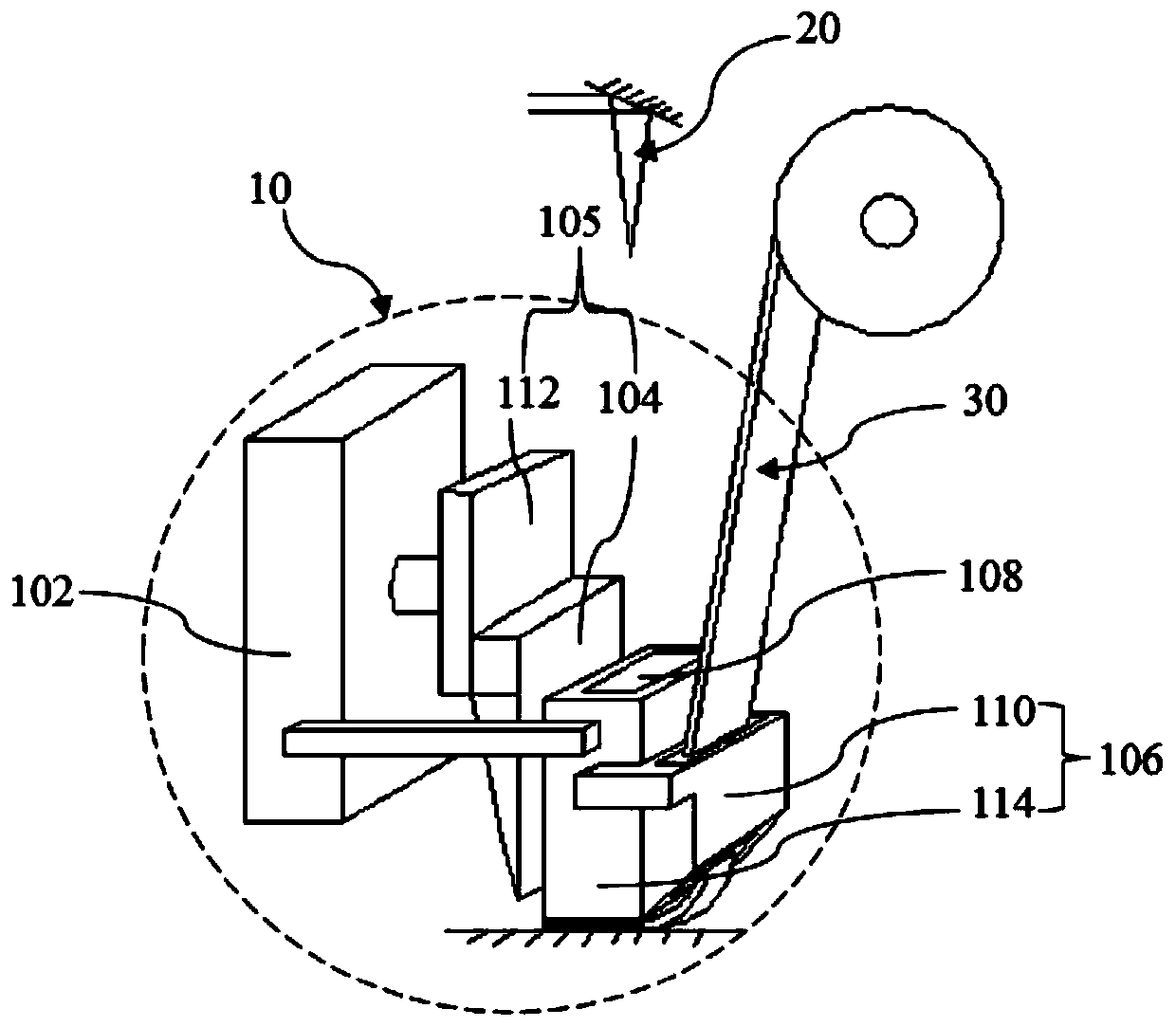

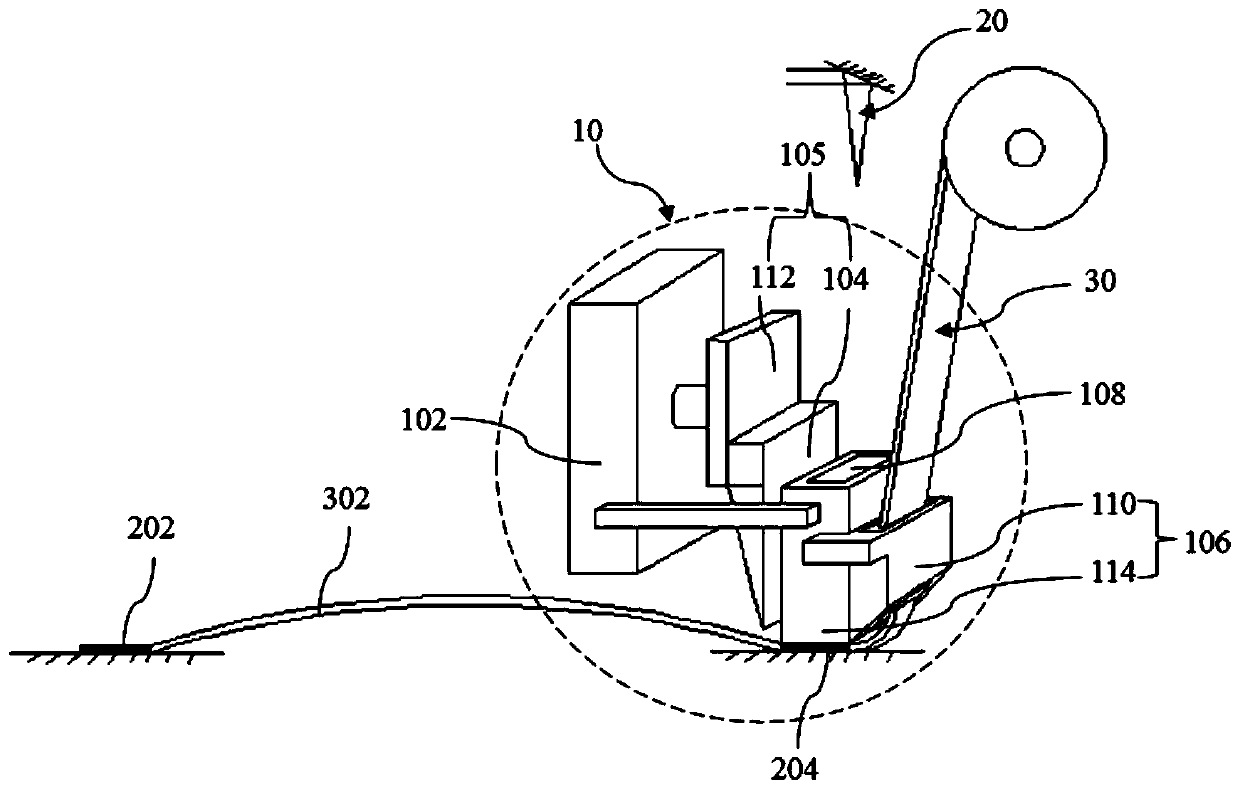

[0031] see Figure 1 to Figure 3 Shown, the laser welding device of the present invention comprises:

[0032] The welding assembly 10 includes a movable welding seat 102 and a pressing device 106 installed on the welding seat 102, and the pressing device 106 is provided with a through hole 108;

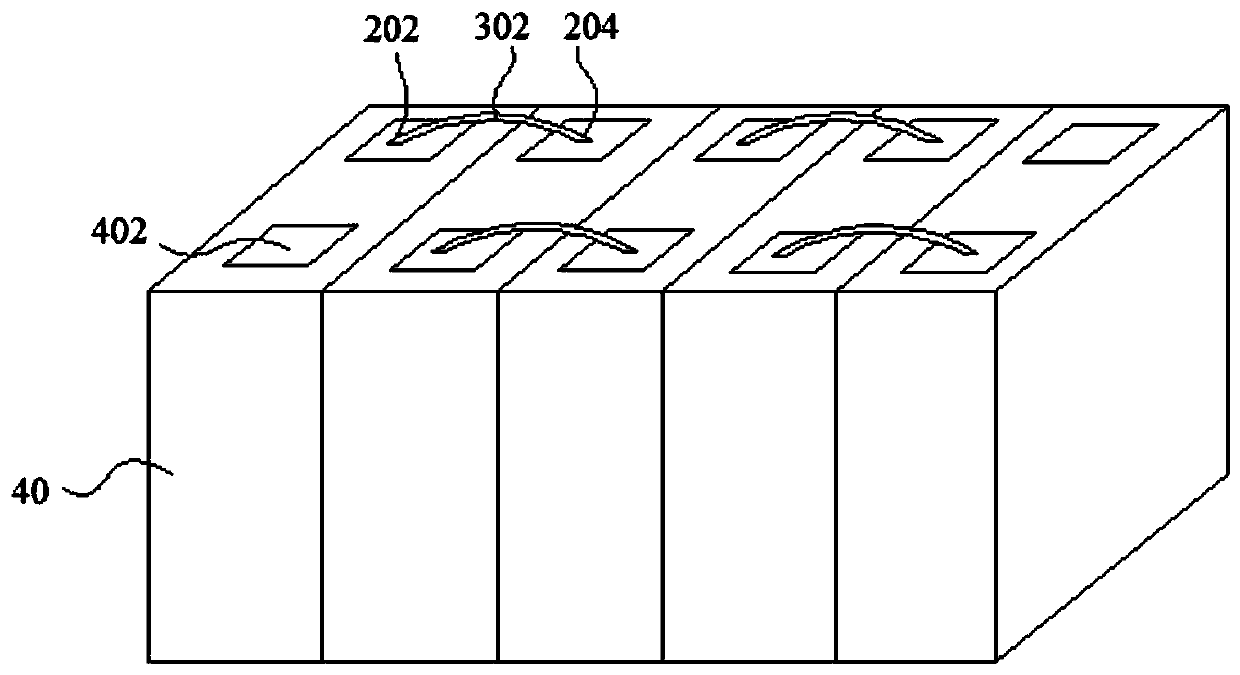

[0033] A connecting band 30, one end of the connecting band 30 is compressed on the pole 402 of the battery 40 through the pressing device 106; and

[0034] A laser generator 20, the laser emitted by the laser generator 20 ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com