Welding method of tungsten-titanium-copper target assembly

A tungsten-titanium target and welding method technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of large deformation, low welding strength, inability to achieve welding, etc., achieve high welding strength, prevent oxidation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In the prior art, the welding process of the tungsten-titanium target and the copper back plate is a brazing process using tin solder or indium solder as the solder. The melting point of the above-mentioned tin solder or indium solder is lower than 250°C. details as follows:

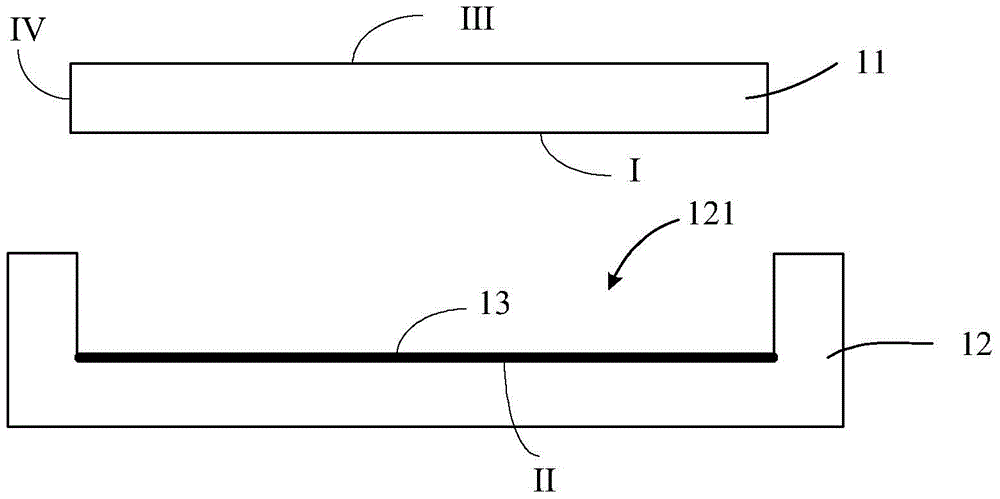

[0035] refer to figure 1 , providing a tungsten-titanium target material 11 and a copper back plate 12 . The tungsten-titanium target 11 is a cylinder, including a circular surface I to be welded, a surface III to be sputtered opposite to the surface I to be welded, and a side IV connecting the surface I to be welded and the surface III to be sputtered. The copper back plate 12 has a groove 121 for accommodating the tungsten-titanium target 11 . The height of the side wall of the groove 121 is greater than the height of the side IV of the tungsten-titanium target 11 . Then, the solder layer 13 is disposed on the bottom surface II of the groove 121 . Next, the tungsten-titanium target 11 is pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com