Combined button and processing technology thereof

A processing technology and button technology, applied in the direction of buttons, fasteners, clothing, etc., can solve the problems of large distance, small number of metal buckle feet, reduced processing efficiency, etc., and achieve the effect of high connection strength, not easy to fall off, and high processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

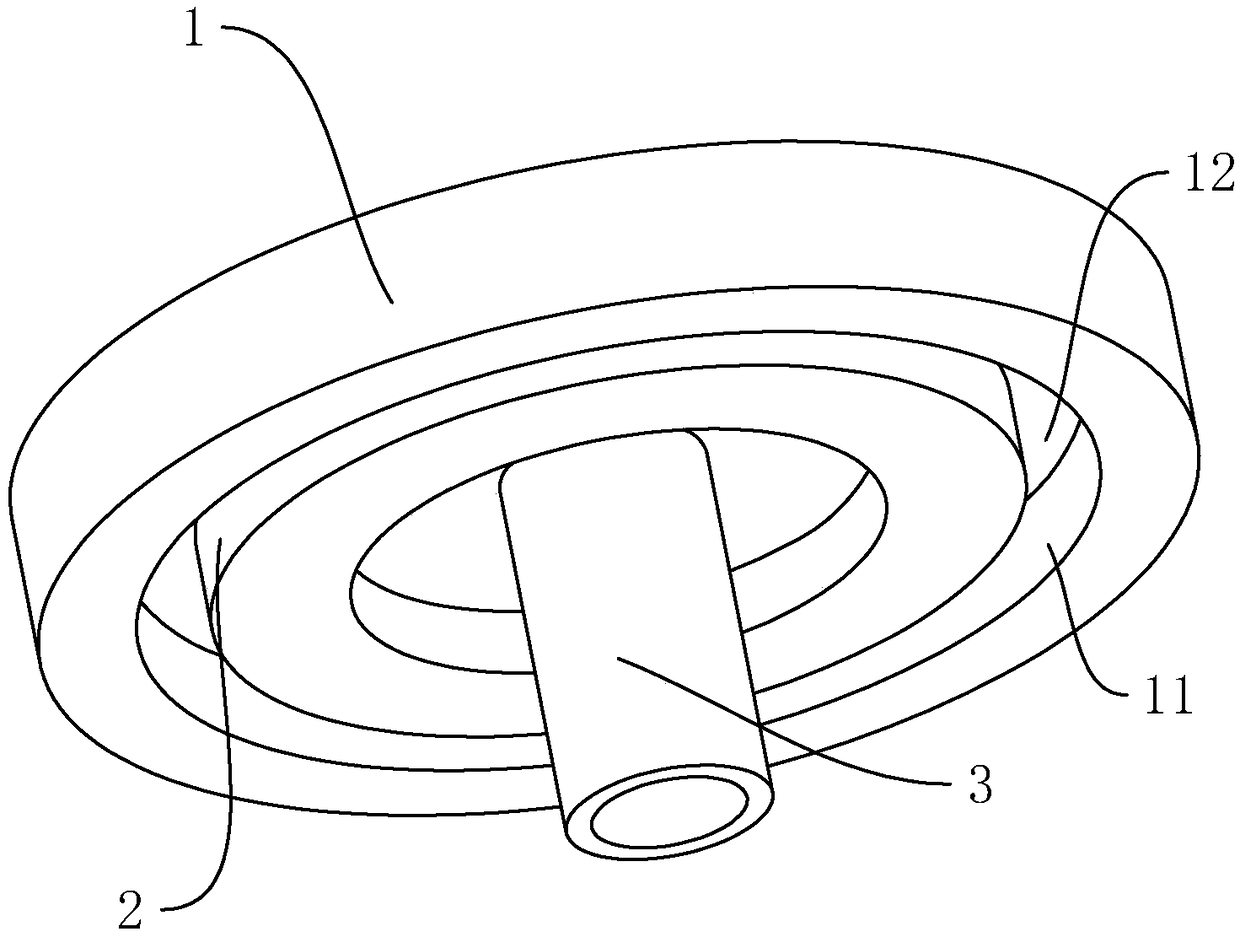

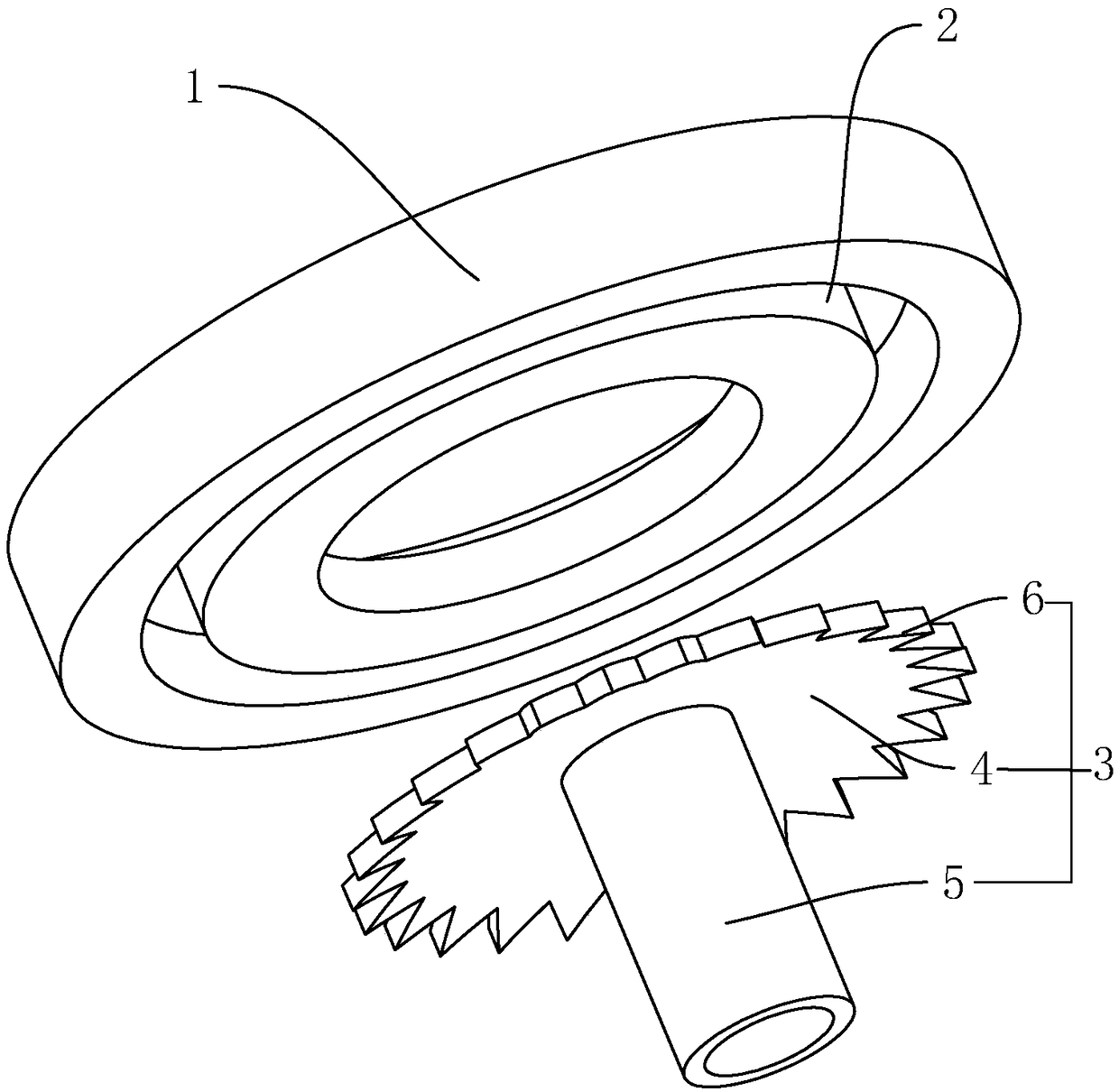

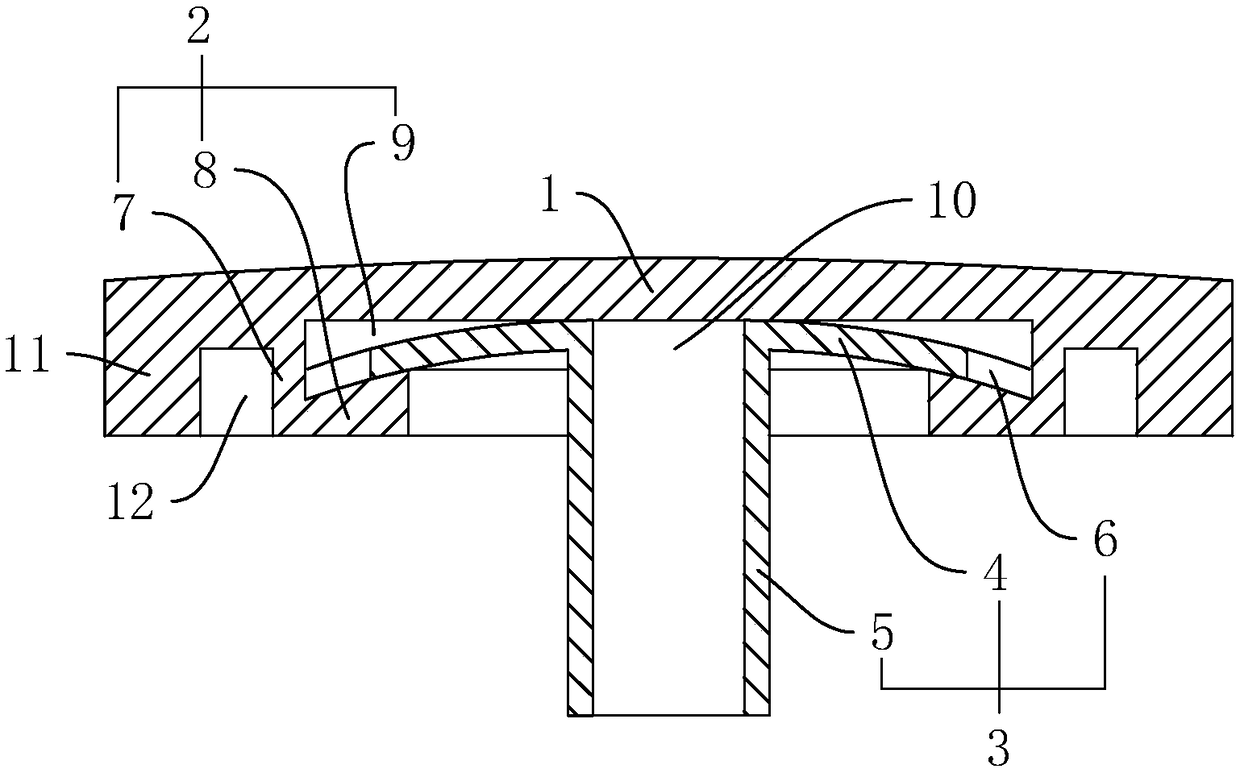

[0039]Embodiment 2: A processing technology for a combined button, the difference from Embodiment 1 is that it includes the following steps, S1: the button cover 1 is formed, the mold is opened according to the shape and size of the button cover 1, and the required button is injected by an injection molding machine. Buckle the cover 1, then cool and demould; S2: Form the buckle foot 3, place the tubular metal material on the punching machine, use a stamping die that matches the shape of the buckle foot 3, punch out the buckle foot 3 through the punching machine; S3: Stamping and merging, put the buckle cover 1 on the button punching machine, and then place the clamping part 4 of the buckle foot 3 in the clamping ring 2 of the buckle cover 1, the punching machine works and squeezes the clamping ring 2 to make the buckle The upper edge of the adapter ring 2 is deformed toward the center to form the hooking portion 8 , and at this time the hooking portion 8 and the inner wall of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com