Preparation method of aluminum-phosphorus alloy for hypereutectic aluminum-silicon modification

An aluminum-phosphorus alloy and hypereutectic technology, which is applied in the field of preparation of aluminum-phosphorus alloys for hypereutectic aluminum-silicon modification, can solve the problem of no preparation method and the like, and achieve the effects of good refining effect, simple operation and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

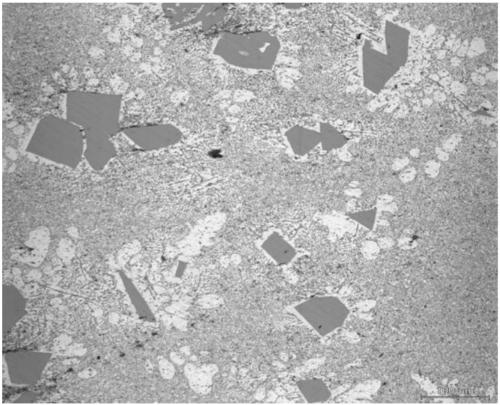

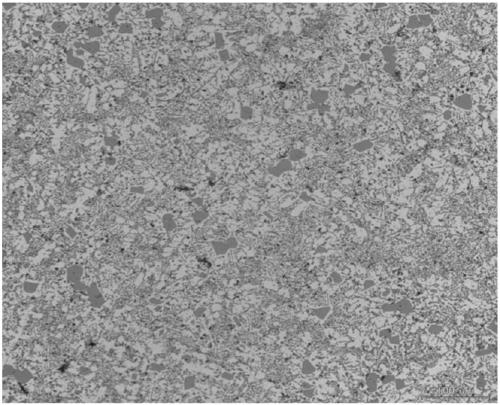

Image

Examples

Embodiment 1

[0020] (1) Melt 198.5g of industrial pure aluminum and adjust the temperature of molten aluminum to 1400°C;

[0021] (2) Wrap 12g of aluminum phosphide particles with 1.5g of aluminum foil and press them into molten aluminum. 3.03% of mass;

[0022] (3) After the aluminum phosphide is dissolved in the molten aluminum, keep it warm for 2 minutes, and pour the aluminum-phosphorus alloy liquid into the metal tank made of steel plate.

[0023] According to the above operations, an aluminum-phosphorus alloy with a phosphorus content of 3.03% can be obtained.

Embodiment 2

[0025] (1) Melt 198g of industrial pure aluminum and adjust the temperature of the molten aluminum to 1800°C;

[0026] (2) 24g of aluminum phosphide particles are wrapped together with 2g of aluminum foil, pressed into molten aluminum with a quartz tube, and the content of phosphorus accounts for 5.73% of the total mass of the molten aluminum;

[0027] (3) After the aluminum phosphide is dissolved in the molten aluminum, keep it warm for 6 minutes, and pour the aluminum-phosphorus alloy liquid into the metal tank made of steel plate.

[0028] According to the above operations, an aluminum-phosphorus alloy with a phosphorus content of 5.73% can be obtained.

Embodiment 3

[0030] (1) Melt 200g of industrial pure aluminum and adjust the temperature of the molten aluminum to 1400°C;

[0031] (2) 4g of aluminum phosphide particles to be added are wrapped together with aluminum foil, and pressed into molten aluminum with a quartz tube, and the content of phosphorus accounts for 1.05% of the total mass of the molten aluminum;

[0032] (3) After the aluminum phosphide is dissolved in the molten aluminum, keep it warm for 2 minutes, and pour the aluminum-phosphorus alloy liquid into the metal tank made of steel plate.

[0033] According to the above operations, an aluminum-phosphorus alloy with a phosphorus content of 1.05% can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com