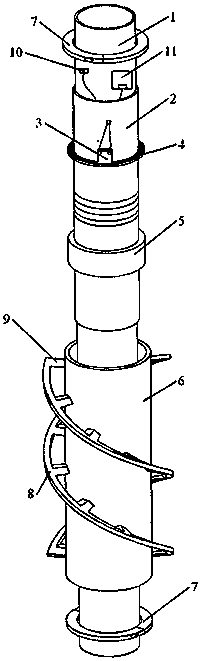

Vibration resisting strakerotating power generation and corrosion protection device and method

A technology of strakes and accumulators, applied in earthwork drilling, engine components, machines/engines, etc., can solve the problems of inconvenient on-site adoption and high energy consumption, and achieve the effect of suppressing vortex-induced vibration and suppressing vortex-induced vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

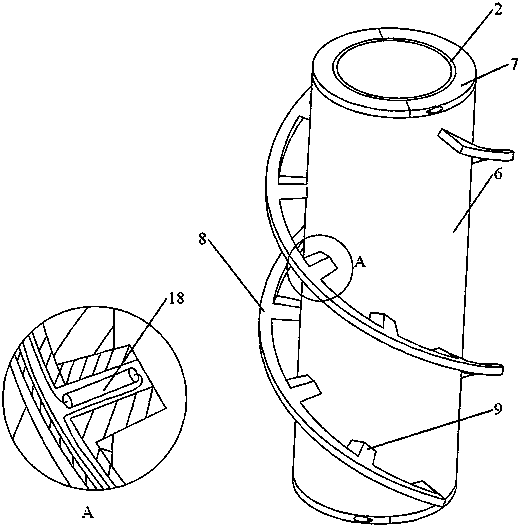

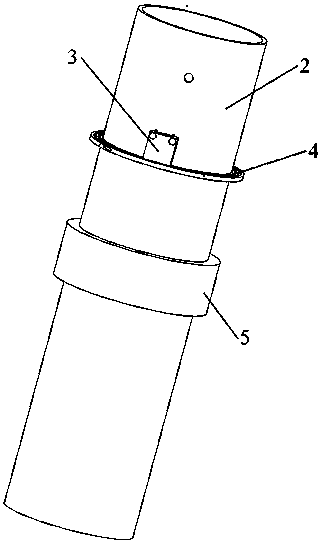

[0038] When installing the device of the present invention, at first the inner cylinder 2 is fixedly installed on the standpipe 1 .

[0039] Secondly, a conductive elastic piece 10 is fixedly glued on the outer wall of the standpipe 1, and the auxiliary anode 11 is also fixed on the outer wall of the standpipe 1, and another conductive elastic piece 10 is fixedly glued on the auxiliary anode 11. Align the bolt holes on the accumulator 3 axially with the bolt holes on the inner cylinder 2, and install and fix the accumulator 3 on the inner cylinder 2 through bolts. The anode of the output joint 12 on the accumulator 3 is fixedly connected to the conductive shrapnel 10 on the auxiliary anode 11 through a wire, and the cathode of the output joint 12 on the accumulator 3 is fixedly connected to the conductive shrapnel 10 on the outer wall of the riser 1 through a wire.

[0040] Next, screw the internal thread on the inner wall of the roller bearing 5 with the external thread on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com