System for obtaining high-lumen-density green light source

A density and green light technology, applied in the field of lighting, can solve the problems of stray light, complex optical path, energy loss of optical path, etc., and achieve the effect of low energy loss, simple optical path and high lumen density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

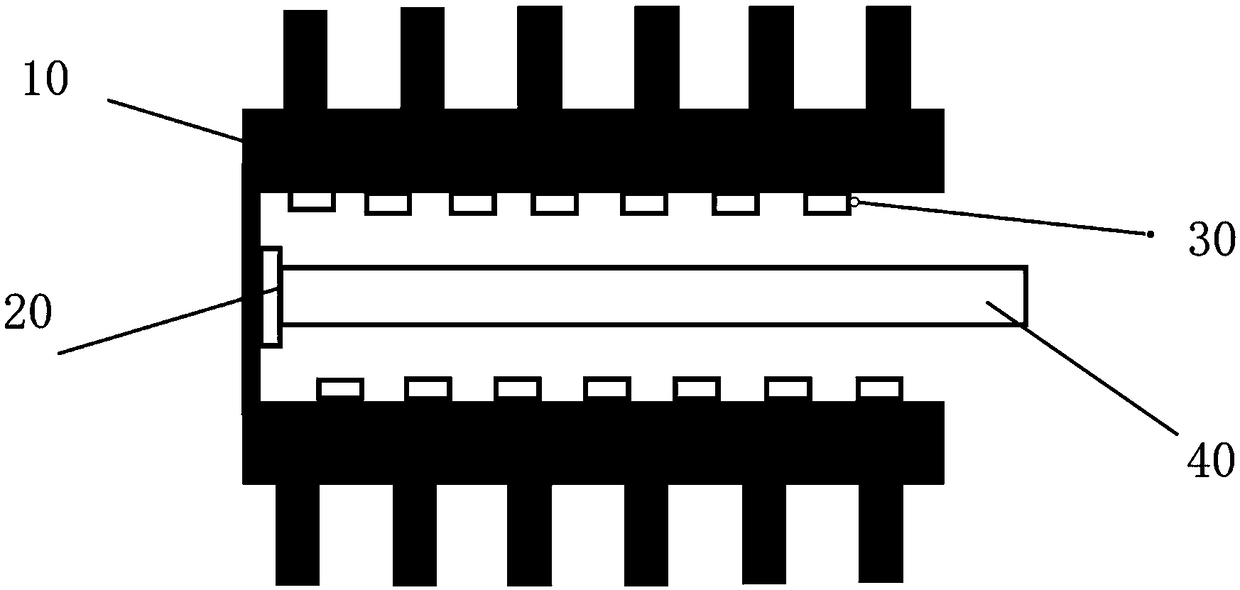

[0024] A system for obtaining high lumen density green light sources such as figure 1 As shown, it includes a heat sink 10, a laser diode module 30, and a fluorescent ceramic plate 40; wherein, the heat sink 10 is composed of two tungsten-copper heat sinks with symmetrical structures, and the inside of the heat sink 10 forms a cavity with only one side opening , a plurality of small holes with the same structure are evenly distributed on the upper and lower inner walls of the cavity; the laser diode module 30 is composed of 50 LD chips with a wavelength of 450.0nm and a peak power of 5.0W, and the LD chips are respectively fixed in the cavity of the heat sink 10 In the small holes on the upper and lower inner walls of each row, 25 chips are fixed in each row, and the upper and lower rows of chips are arranged alternately; the fluorescent ceramic plate 40 is horizontally fixed at the center of the cavity of the heat sink 10, and the two ends of the fluorescent ceramic plate 40 a...

Embodiment 2

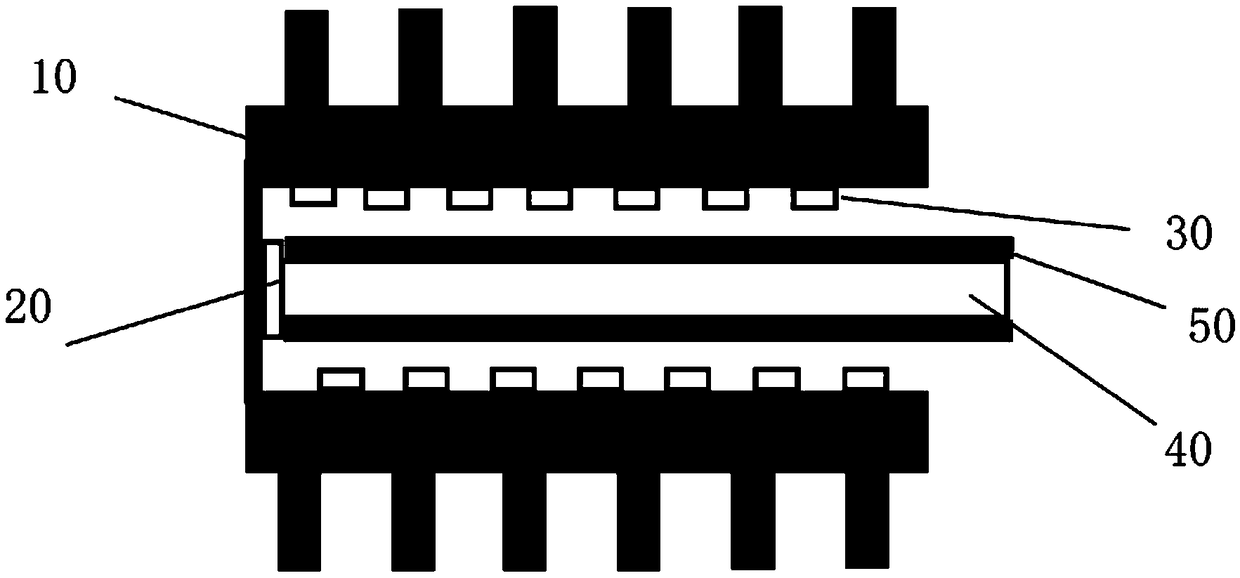

[0029] A system for obtaining high lumen density green light sources such as figure 2 As shown, it includes a heat sink 10, a laser diode module 30, and a fluorescent ceramic plate 40; wherein, the heat sink 10 is composed of two tungsten-copper heat sinks with symmetrical structures, and the inside of the heat sink 10 forms a cavity with only one side opening , a plurality of small holes with the same structure are evenly distributed on the upper and lower inner walls of the cavity; the laser diode module 30 is composed of 60 LD chips with a wavelength of 450.0nm and a peak power of 5.0W, and the LD chips are respectively fixed on the upper and lower inner walls of the heat sink 10 In the holes, 30 are fixed in each row, and the upper and lower rows of LD chips are arranged in a staggered manner; the fluorescent ceramic plate 40 is horizontally fixed at the center of the cavity of the heat sink 10, and the two ends of the fluorescent ceramic plate 40 are precisely polished an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com