Energy storage and heating combined floor

An energy storage, floor technology, applied in the field of flooring, can solve the problems of high power consumption, non-compliance, and peak power consumption of the floor heating floor, and achieve the effects of less occupied floor height, consistent power supply voltage, and convenient power connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

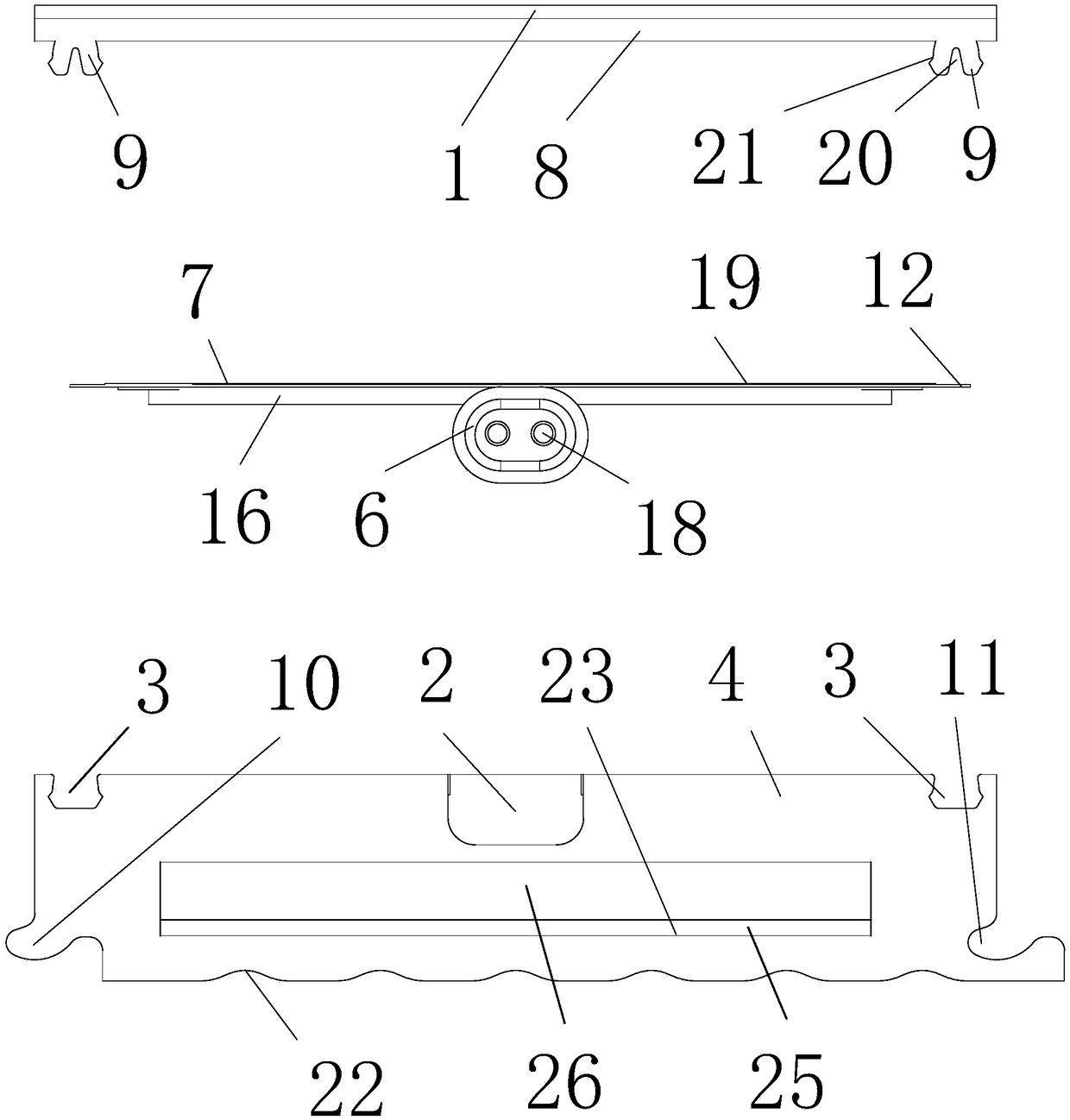

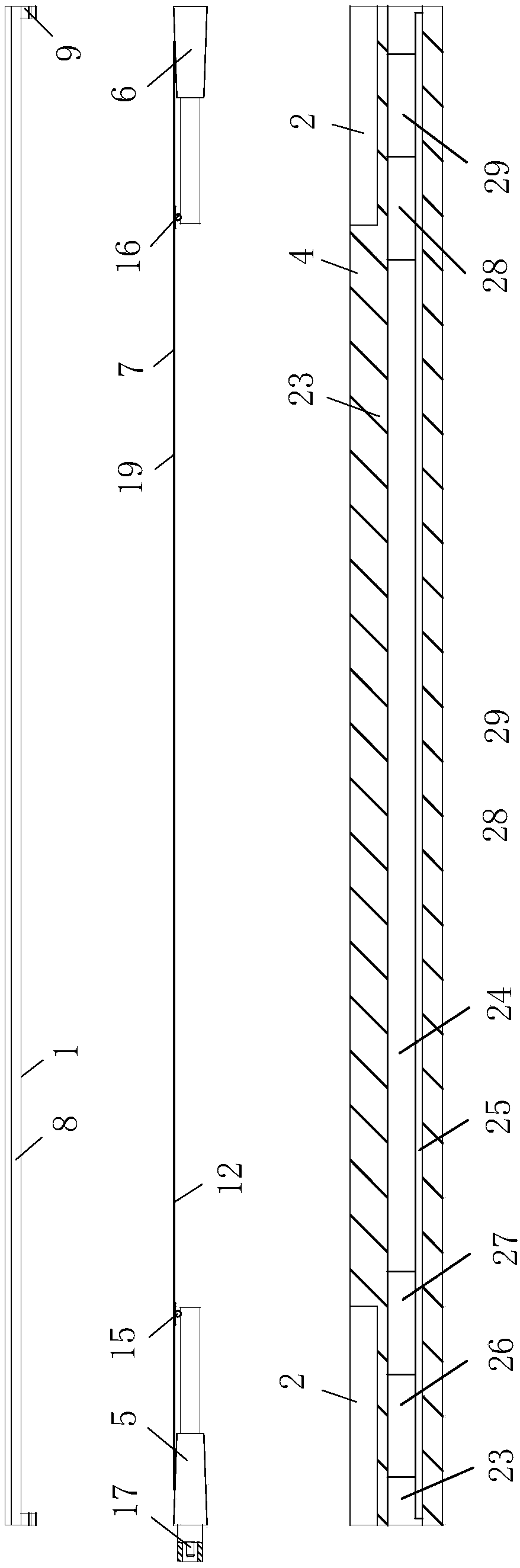

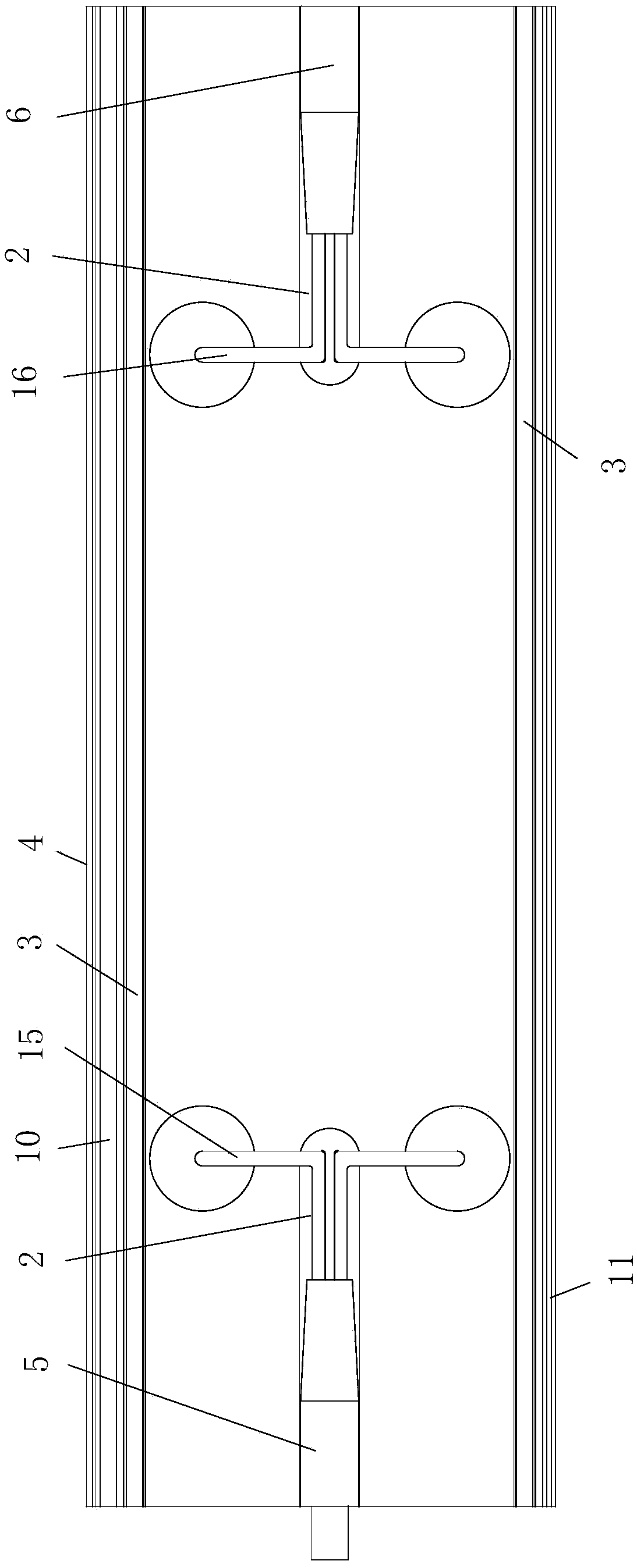

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

[0018] as attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 Shown: an energy storage type heating combination floor, including: a base plate 4, a panel 1, an accommodating cavity 23 provided on the base plate 4, an energy storage power supply device set in the accommodating cavity 23 and provided with a battery 24, located in The graphene heating sheet 7 between the substrate 4 and the panel 1 is provided on the splicing groove 10 at one end of the substrate 4, and the splicing convex strip 11 is provided on the other side of the substrate 4 and adapted to the splicing groove 10; The grid circuit supplies power, the graphene heating sheet 7 works, and the energy storage power supply device stores energy; when the peak power is reached, the grid circuit is disconnected, the energy storage power supply device supplies power, and the graph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com