Air purification integrated device of air conditioner

An air purification device and air purification technology are applied in air conditioning systems, space heating and ventilation, chemical instruments and methods, etc., which can solve the problems of complex air conditioning structure, inability to purify air, inconvenient use, etc. to remove particulate matter and harmful gases, and achieve Good antibacterial effect, light weight and large air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

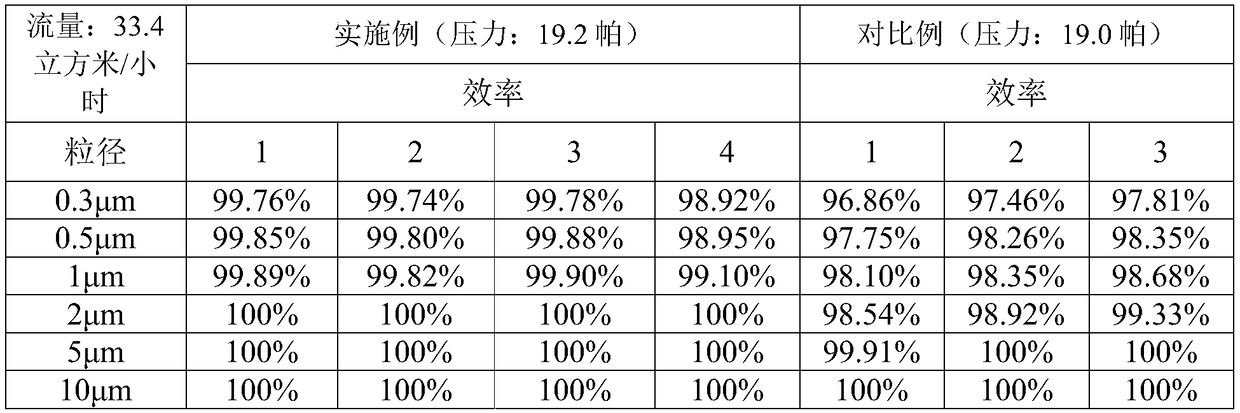

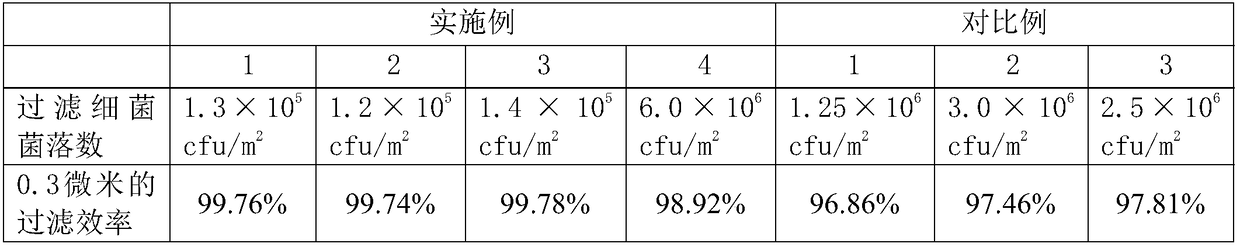

Embodiment 1

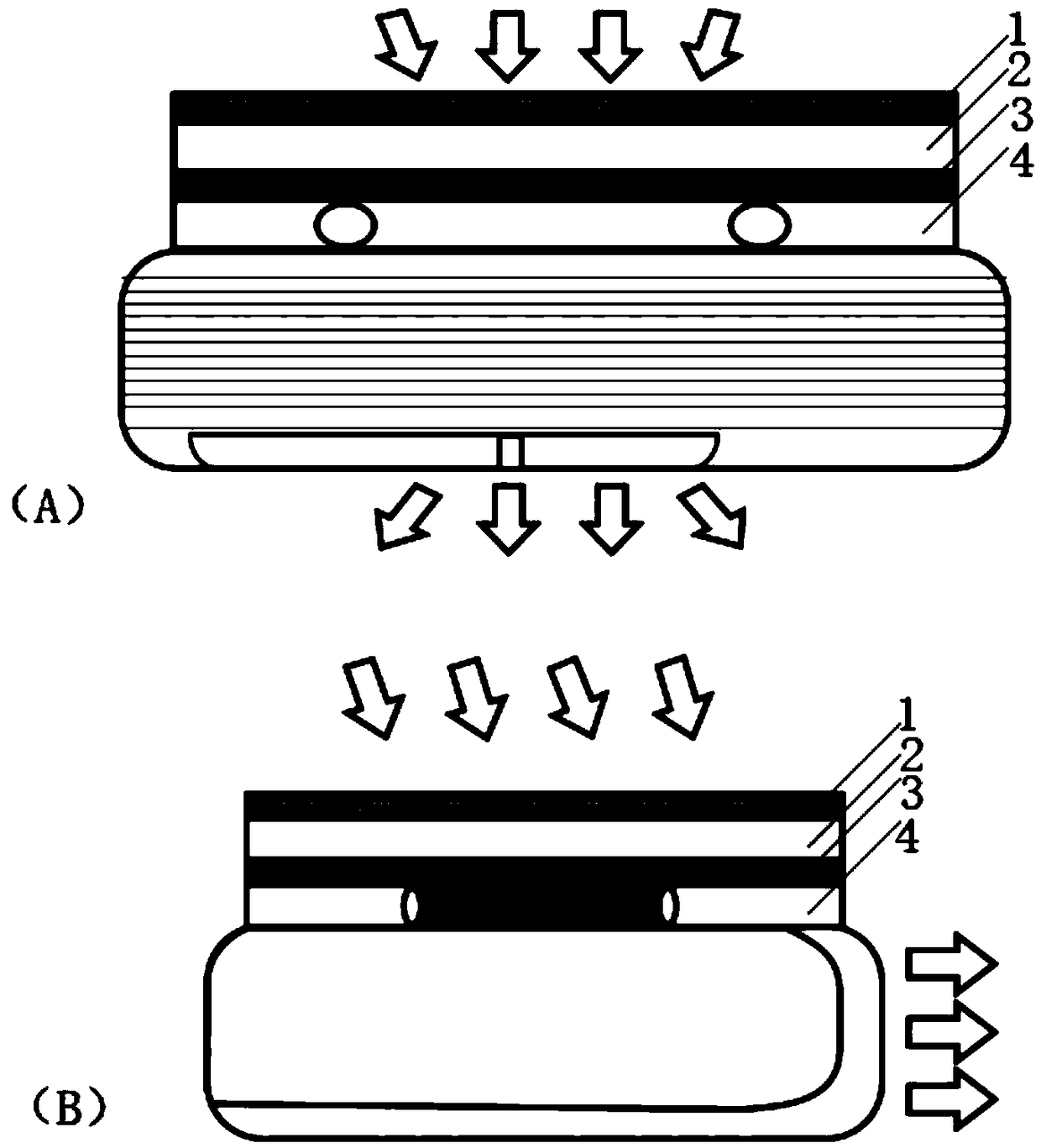

[0034] This embodiment relates to an integrated device for air conditioning and air purification, such as figure 1 As shown, it mainly includes an air purification device fixedly connected to the indoor air conditioner. A purification channel is provided in the device, and a double fan and a multi-stage air purification filter element are arranged in the purification channel. The air inlet of the device is located in the purification channel. The upper end of the channel, the air outlet of the device is located at the rear end of the multi-stage air purification filter element. The indoor air conditioner is mainly used as a temperature control device with a temperature control device inside. The temperature control device includes circulation pipes, pipelines, small compressors, etc. The circulation tube is filled with compressed solution. When the air purification device is running automatically, the fan rotates to drive the air to enter the air purification device from the ...

Embodiment 2

[0041] This embodiment relates to an air-conditioning and air purification integrated device, which is basically the same as Embodiment 1, except that:

[0042] The primary filter uses graphene composite polyester fiber filter cloth. During preparation, melt the PET chips at 210°C, cool down to 150°C, add graphene powder and stir for 3 hours, and gradually heat up to 170°C during the stirring process; then cool to room temperature, and mechanically pulverize the molten mixture into Masterbatch; Masterbatch is added in spinneret and is prepared into this graphene composite polyester fiber filter cloth; The mass ratio of described graphene and PET chips is 1:100.

[0043] The HEPA filter uses graphene composite polypropylene filter. During preparation, melt polypropylene at 180°C, slowly cool down to 130°C, add graphene powder and stir for 4 hours, and gradually heat up to 170°C during the stirring process; then cool to 100°C, and mechanically pulverize the molten mixture Beco...

Embodiment 3

[0046] This embodiment relates to an air-conditioning and air purification integrated device, which is basically the same as Embodiment 1, except that:

[0047] The primary filter uses graphene composite polyester fiber filter cloth. During preparation, melt the PET chips at 280°C, cool down to 150°C, add graphene powder and stir for 1 hour, and gradually heat up to 200°C during the stirring process; then cool to room temperature, and mechanically pulverize the molten mixture into Masterbatch; masterbatch is added in spinneret and is prepared into this graphene composite polyester fiber filter cloth; the mass ratio of described graphene and PET chips is 3:100.

[0048] The HEPA filter uses graphene composite polypropylene filter. During preparation, melt polypropylene at 300°C, slowly cool down to 150°C, add graphene powder and stir for 1 hour, and gradually heat up to 190°C during the stirring process; then cool to 100°C, and mechanically pulverize the molten mixture Become...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com