Hot air drying method for undyed yarn

The technology of hot air drying and hot air drying machine is applied in the field of yarn printing and dyeing, and can solve the problems of high energy consumption, macular generation on the cloth surface, low energy consumption and production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

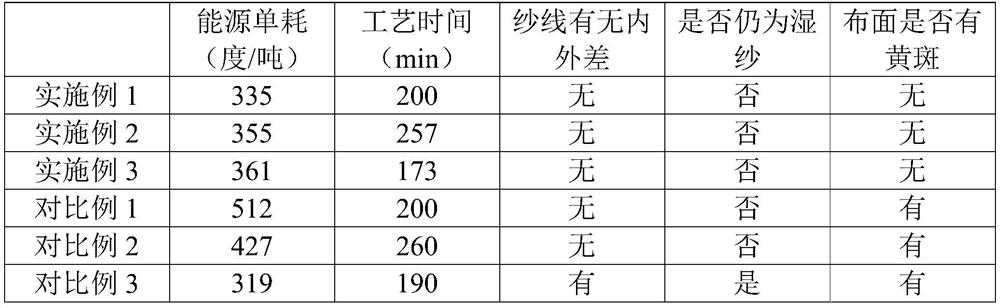

Examples

Embodiment 1

[0036] This embodiment is a hot-air drying method for undyed yarns. The undyed yarns are yarns that have only been pre-treated before the dyeing process, and are usually called white yarns. The directly obtained undyed yarn is dried with hot air using a GALVANIN hot air dryer, including the following steps:

[0037] (1) Obtain undyed yarn and place it on a hot-air dryer, and carry out temperature-raising treatment on the undyed yarn. The process of the temperature-raising treatment is: under the condition of a pressure of 6.5Bar, the The temperature of the air inlet is raised to 110°C, and the heating time is 10 minutes.

[0038] (2) heat preservation treatment is carried out on the undyed yarn after the temperature rise, the process of the heat preservation treatment is: drying for 60 minutes at a pressure of 6.5 Bar and an air inlet temperature of 110° C. of the hot air dryer.

[0039] (3) Perform cooling treatment on the undyed yarn after heat preservation, the process of ...

Embodiment 2

[0042] This embodiment is a hot-air drying method for undyed yarns. The undyed yarns are yarns that have only been pre-treated before the dyeing process, and are usually called white yarns. The directly obtained undyed yarn is dried with hot air using a GALVANIN hot air dryer, including the following steps:

[0043] (1) Obtain undyed yarn and place it on a hot-air dryer, and carry out temperature-raising treatment on the undyed yarn. The process of the temperature-raising treatment is: under the condition of a pressure of 4.5Bar, the The temperature of the air inlet is raised to 95°C, and the heating time is 12 minutes.

[0044] (2) heat preservation treatment is carried out on the undyed yarn after heating, the process of heat preservation treatment is as follows: drying for 80 minutes at a pressure of 4.5 Bar and an inlet air temperature of 95° C. of the hot air dryer.

[0045] (3) Perform cooling treatment on the undyed yarn after heat preservation, the process of the cool...

Embodiment 3

[0048] This embodiment is a hot-air drying method for undyed yarns. The undyed yarns are yarns that have only been pre-treated before the dyeing process, and are usually called white yarns. The directly obtained undyed yarn is dried with hot air using a GALVANIN hot air dryer, including the following steps:

[0049] (1) Obtain undyed yarn and place it on a hot-air dryer, and carry out temperature-raising treatment on the undyed yarn. The process of the temperature-raising treatment is: under the condition of a pressure of 7 Bar, heat the hot-air dryer The wind temperature rises to 115°C, and the heating time is 8 minutes.

[0050] (2) heat preservation treatment is carried out on the undyed yarn after the temperature rise, the process of the heat preservation treatment is: drying for 40 minutes at a pressure of 7 Bar and the inlet air temperature of the hot air dryer at 115°C.

[0051] (3) Perform cooling treatment on the undyed yarn after heat preservation, the process of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com