Experimental device and experimental method for measuring ultimate contact stress of connected part in bolt joint

A technology of bolt joints and contact stress, applied in measuring devices, using stable tension/pressure to test material strength, instruments, etc., can solve problems such as contact surface depressions, plastic deformation of materials, etc., and achieve simple processing, accurate force measurement, Simple effects in preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

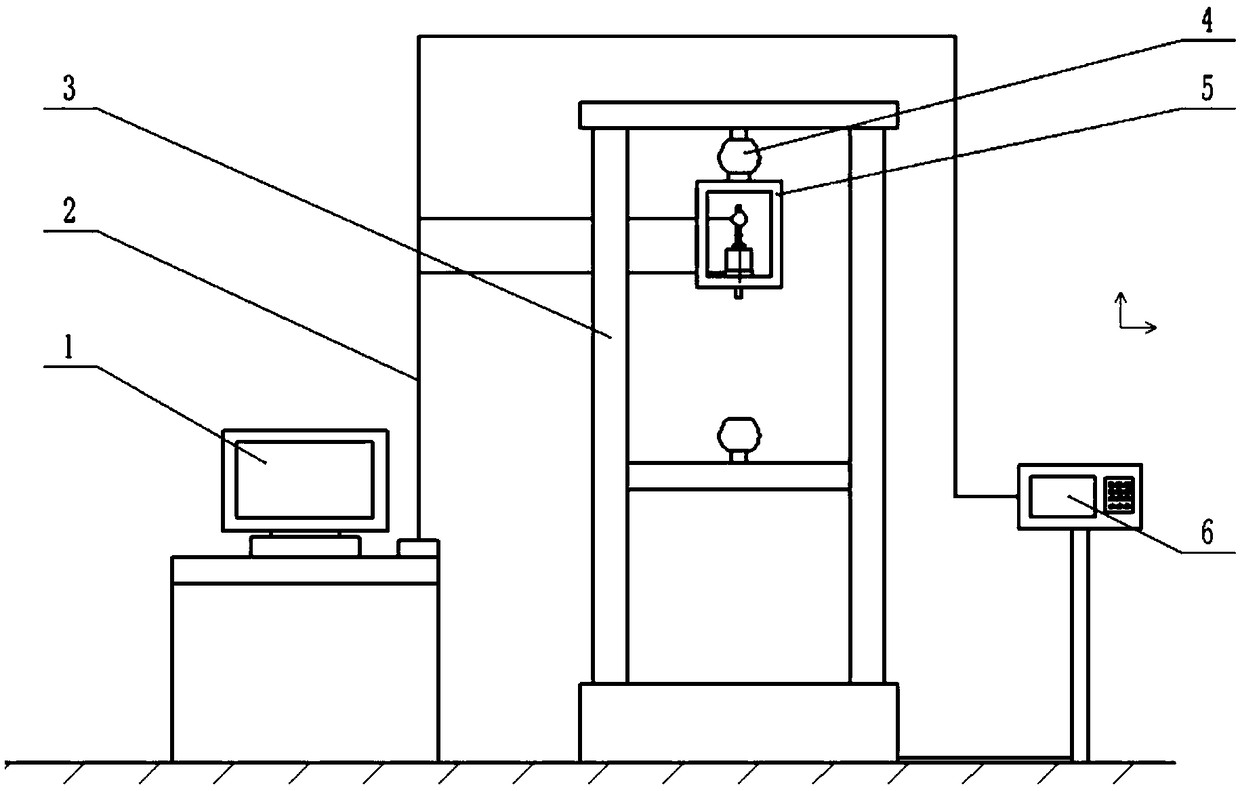

[0044] Combine below Figure 1-8 And experimental method, the present invention is described in more detail.

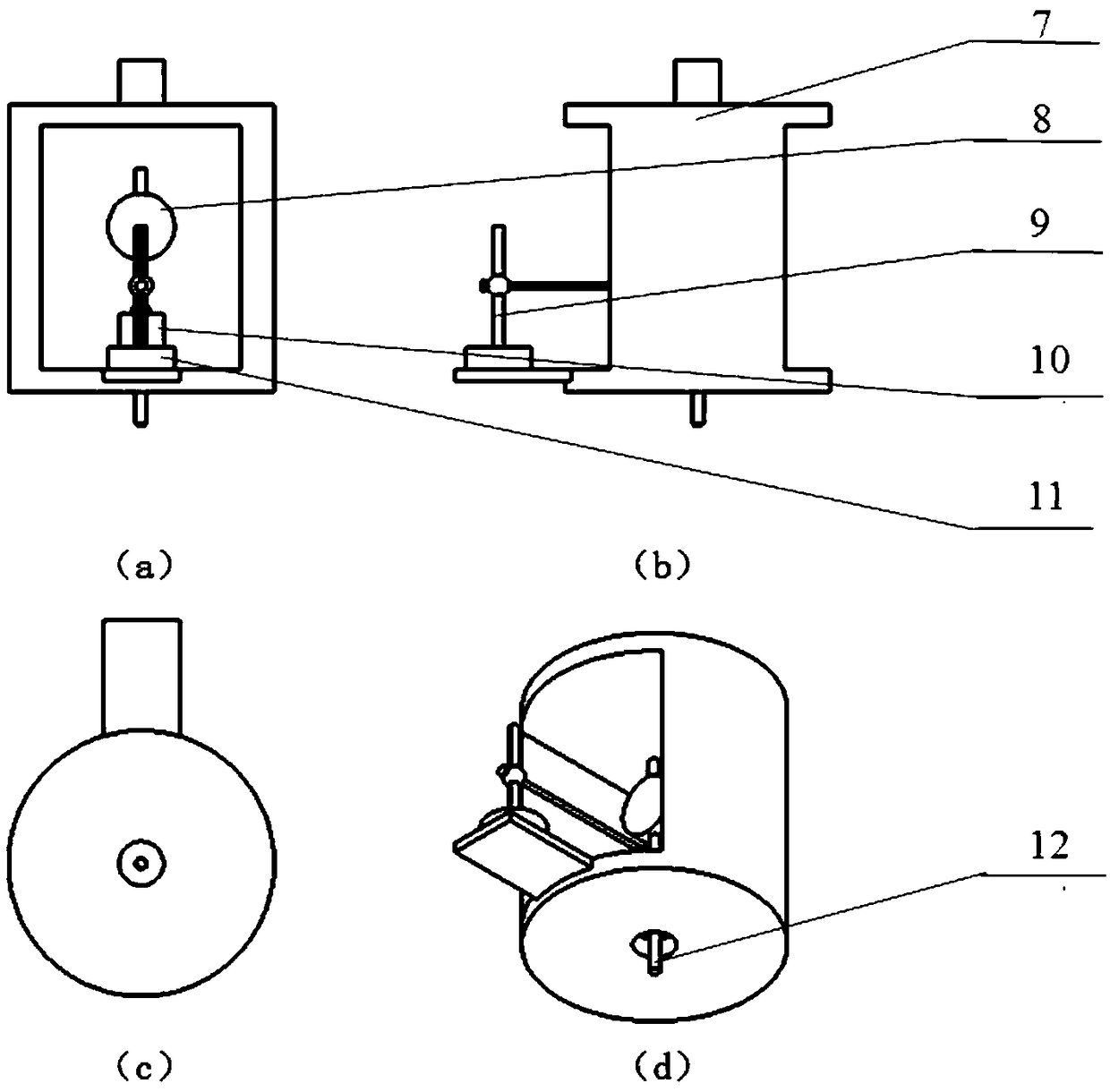

[0045] Experimental device for measuring short-term relaxation effects in bolted joints provided according to the invention, such as figure 1 , figure 2 As shown, it includes a stretching machine 3, a clamp 7, a dial indicator 8, a magnetic base 9, a test piece 10, a sensor 11, and a polished rod bolt 12. The material types and shapes and sizes of the test pieces 10 used in the experiment are the same.

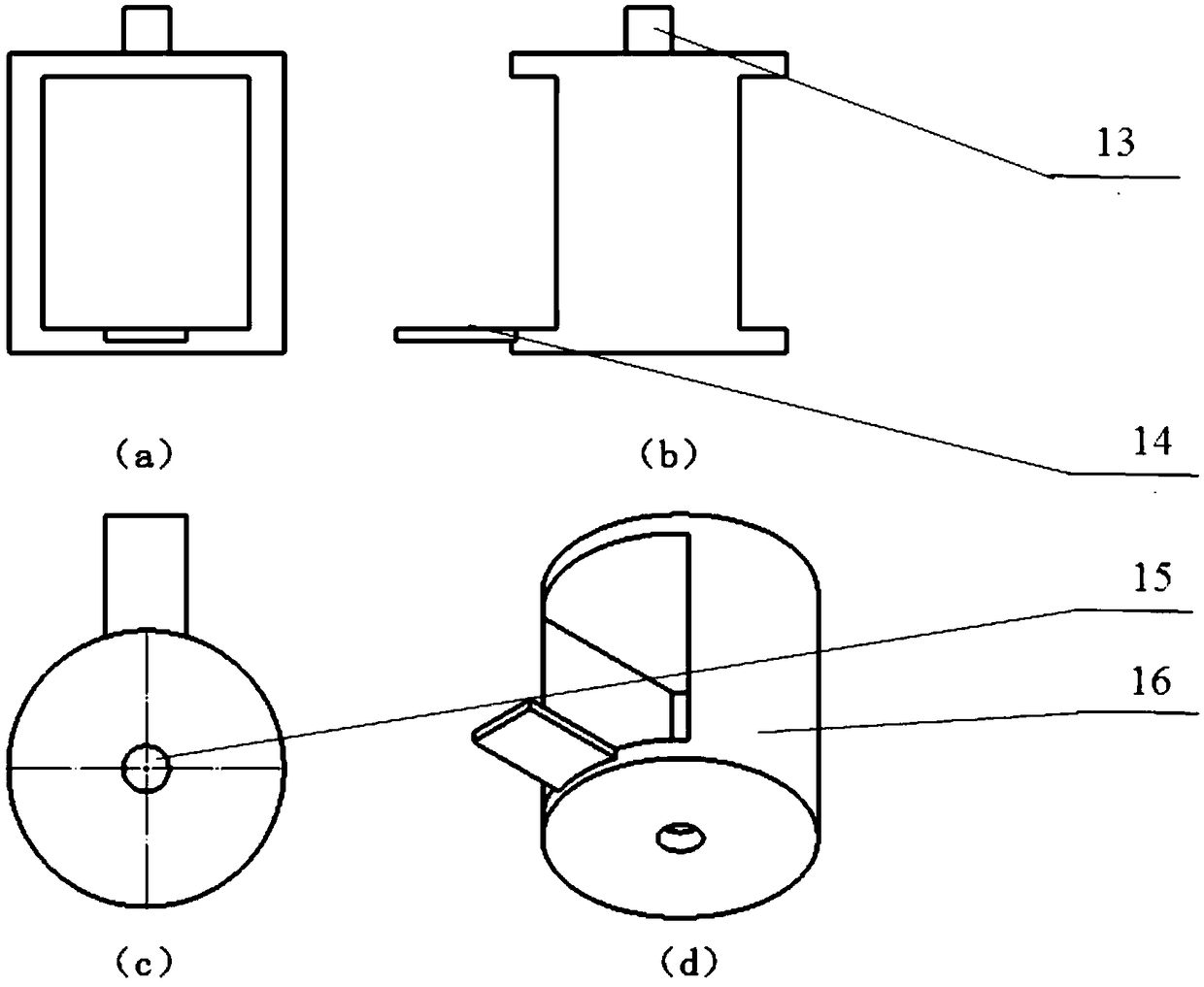

[0046] Design of non-purchased parts: Fixture 7 must ensure the strength requirements, and heat treatment after processing is completed to enhance rigidity. The design size of the fixture 7 is that the thickness of the upper and lower end faces is 20mm, the upper chuck 13 of the fixture has a diameter of 40mm and a width of 40mm, the outer diameter is 240mm and the height is 260mm, and the diameter of the bottom hole 15 of the fixture is 40mm. Dial indicator 8, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com