On-chip micro electron source and manufacturing method thereof

An electron source and miniature technology, applied in the field of electronic science and technology, can solve the problem of small emission current and achieve the effect of improving heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

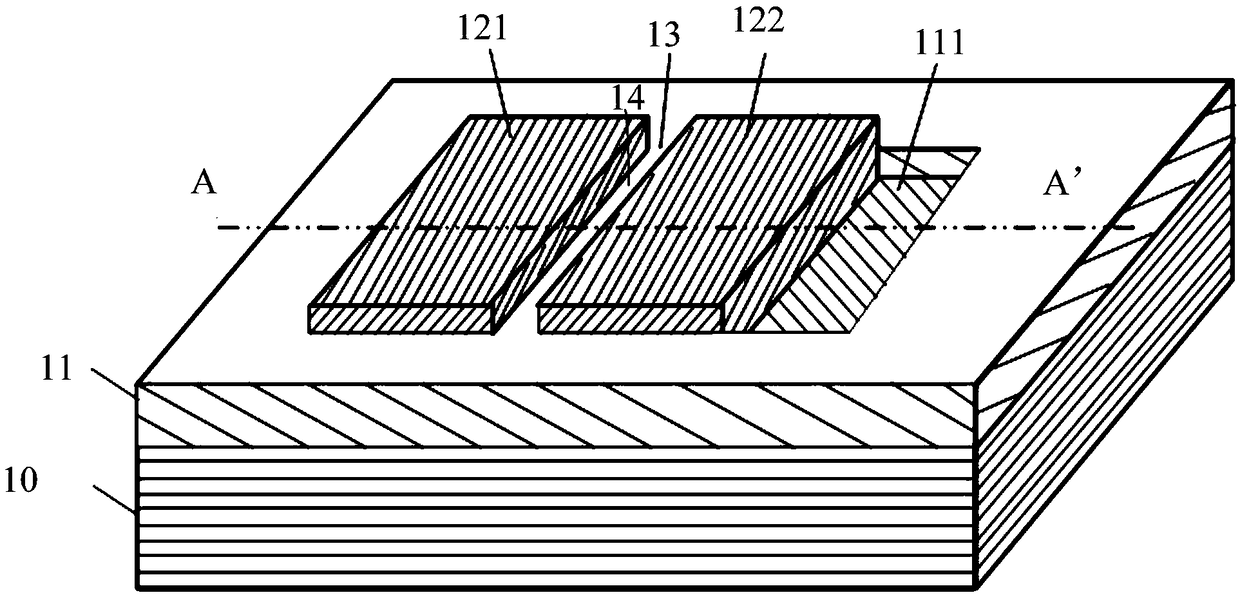

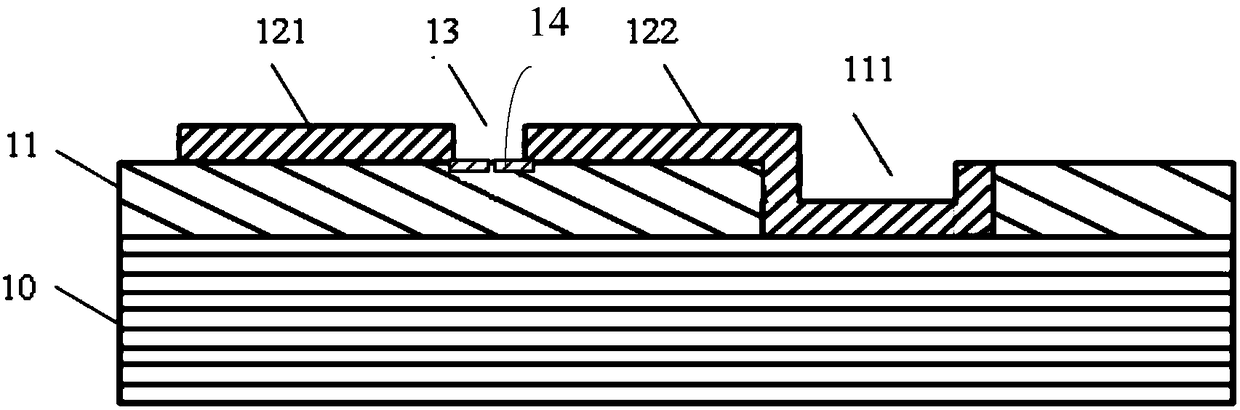

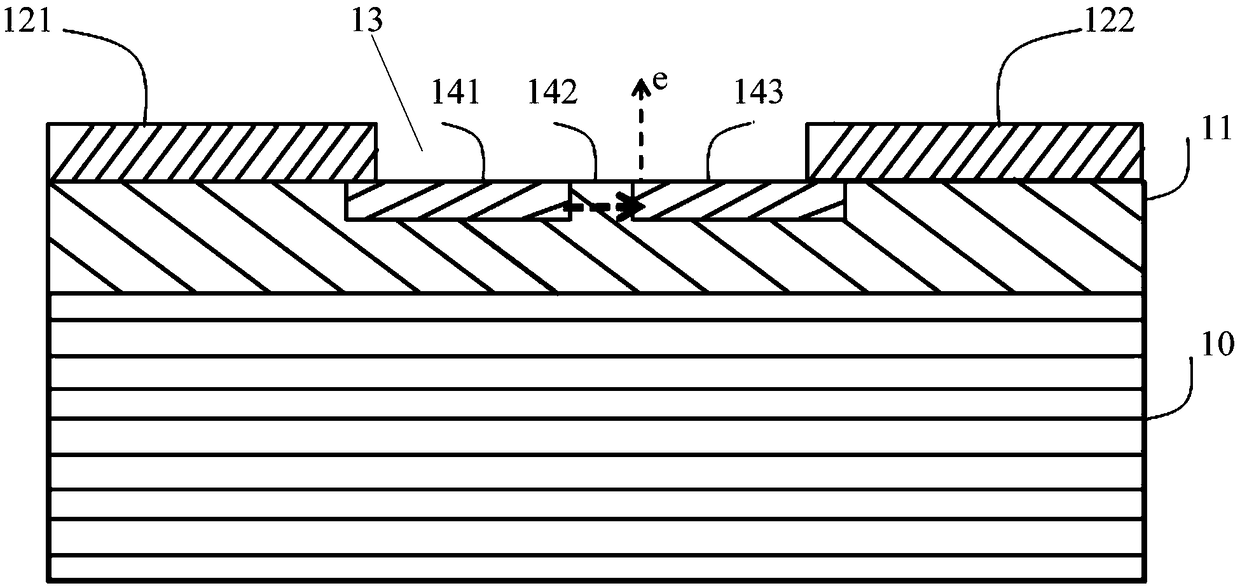

[0061] see figure 1 and figure 2 , figure 1 It is a schematic diagram of the three-dimensional structure of an on-chip micro-electron source provided in Embodiment 1 of the present application, figure 2 for the on-chip miniature electron source along the figure 1 The schematic diagram of the cross-sectional structure of the dotted line A-A'.

[0062] An on-chip miniature electron source comprising:

[0063] Heat conduction layer 10;

[0064] An insulating layer 11 located on the heat conducting layer 10, wherein the insulating layer 11 is made of a resistive material, and a through hole 111 is arranged on it;

[0065] An electrode pair located on the insulating layer 11, the electrode pair includes a first electrode 121 and a second electrode 122, and the second electrode 122 is in contact with the heat conducting layer 10 through the through hole 111;

[0066] Wherein, there is a gap 13 between the first electrode 121 and the second electrode 122 ; a tunnel junction 1...

Embodiment 2

[0108] see Figure 7 and Figure 8 , Figure 7 It is a schematic diagram of the three-dimensional structure of an on-chip micro-electron source provided in Embodiment 2 of the present application, Figure 8 for the on-chip miniature electron source along the Figure 7 The schematic diagram of the cross-sectional structure of B-B' in the middle.

[0109] An on-chip miniature electron source comprising:

[0110] heat conducting layer 70;

[0111] An insulating layer 71 located on the heat conducting layer 70, wherein the insulating layer 71 is made of a resistive material, and a plurality of through holes 711 are arranged on it;

[0112] A plurality of electrode pairs located on the insulating layer 71, each electrode pair includes a first electrode 721 and a second electrode 722, wherein each second electrode 722 corresponds to a through hole 711, and each second electrode 722 communicates with the through hole The heat conduction layer 70 is contacted and connected; the ...

Embodiment 3

[0151] It should be noted that the on-chip micro-electron source provided by the embodiment of the present application can be improved on the basis of the first or second embodiment above. As an example, the embodiment of the present application is obtained by improving the second embodiment.

[0152] see Figure 11 and Figure 12 , Figure 11 It is a schematic diagram of the three-dimensional structure of another on-chip micro-electron source provided in Embodiment 3 of the present application, Figure 12 for the on-chip miniature electron source along the Figure 11 The schematic diagram of the cross-sectional structure of C-C'.

[0153] In addition to all the components in Embodiment 2, the on-chip micro-electron source provided in this embodiment may also include:

[0154] Lead out electrode 110;

[0155] Wherein, the lead-out electrode 110 includes: a lead-out electrode layer 1101 and an insulating support structure 1102 located on one side of the lead-out electrode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com