Printed circuit board product coding device and method

A technology for printed circuit boards and coding devices, which is applied in the directions of printed circuits, printed circuit manufacturing, printed circuit components, etc., can solve the problem of high successful recognition rate, achieve low equipment investment costs, realize batch automation operations, and good traceability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

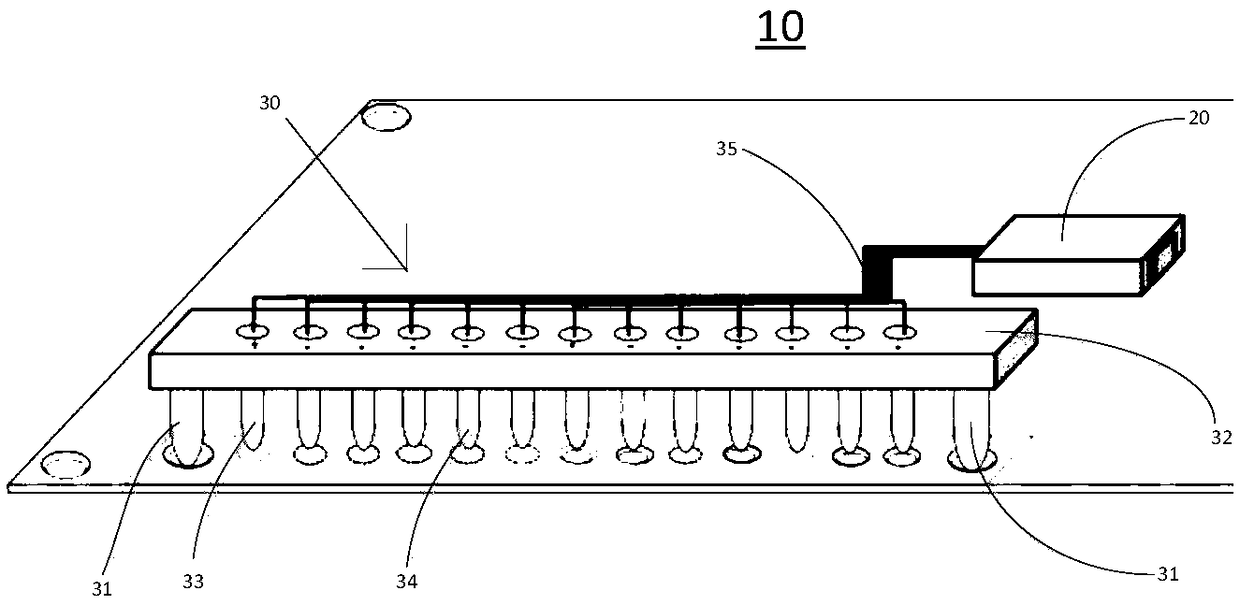

[0019] see figure 1 , shows a printed circuit board product coding device 10, which includes a decoder 20 and an electrical test assembly 30, the electrical test assembly 30 is electrically connected to the decoder 20; the electrical test assembly 30 includes a positioning guide post 31. Fixed post 32, common pin 33, multiple test pins 34 and test leads 35, the positioning guide post 31, common pin 33 and test pin 34 are fixed by the fixed post 32, the common pin 33 and multiple test pins 34 is electrically connected to the decoder 20 through the test wire 35, the distance between the plurality of test pins 34 is consistent, the positioning guide post 31 is set on both sides of the fixed post 32, and the common pin 33 is set on the positioning guide post 31 and test pin 34.

[0020] Preferably, there are 12 test needles 34, and the 12 test need...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com