Preparation method of efficient formaldehyde purification material suitable for filling air purifier

An air purifier and formaldehyde purification technology, applied in chemical instruments and methods, separation methods, physical/chemical process catalysts, etc., can solve the problem that formaldehyde purification materials cannot meet the requirements of filling, and achieve good market application and promotion value, preparation The method is simple and the effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

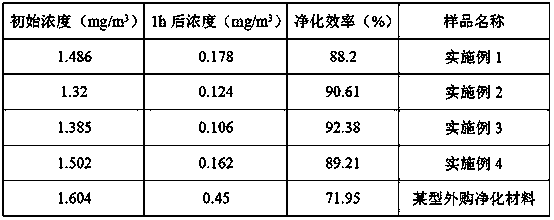

Examples

Embodiment 1

[0017] Take 1000g of columnar activated carbon with a diameter of 20mm, take a certain weight of deionized water according to the water capacity of the activated carbon, take 1.5g of graphene oxide (GO), add 50g of dicyandiamide into deionized water, stir until fully dissolved , Pour the prepared impregnation solution on the activated carbon, and keep stirring, until the impregnation is sufficient, place it for 2 hours and then dry it at 120°C. Fill the prepared purification material into a honeycomb panel with a size of 372mm×272mm×20mm, and use a certain type of air purifier for testing.

Embodiment 2

[0019] Take 1000g of columnar activated carbon with a diameter of 20mm, take a certain weight of deionized water according to the water capacity of the activated carbon, take 5g of graphene oxide (GO), add 65g of dicyandiamide into deionized water, stir until fully dissolved, Pour the prepared impregnating solution on the activated carbon, and keep stirring until the impregnation is sufficient, and dry it at 120°C after standing for 2 hours. Fill the prepared purification material into a honeycomb panel with a size of 372mm×272mm×20mm, and use a certain type of air purifier for testing.

Embodiment 3

[0021] Take 1000g of columnar activated carbon with a diameter of 20mm, take a certain weight of deionized water according to the water capacity of the activated carbon, take 20g of graphene oxide (GO), add 100g of dicyandiamide into deionized water, stir until fully dissolved, Pour the prepared impregnating solution on the activated carbon, and keep stirring, until the impregnation is sufficient, place it for 3 hours and then dry it at 120°C. Fill the prepared purification material into a honeycomb panel with a size of 372mm×272mm×20mm, and use a certain type of air purifier for detection.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com