Automatic switching mechanism for foot stool blank

An automatic transfer and blank technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of slow presentation and inability to maximize production efficiency, so as to improve production efficiency, enhance practicability, and save manpower The effect of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following is a further description of the tripod blank automatic feeding machine provided by the present invention in conjunction with the accompanying drawings. It should be pointed out that the technical solution and design principle of the present invention will be described in detail below with an optimized technical solution.

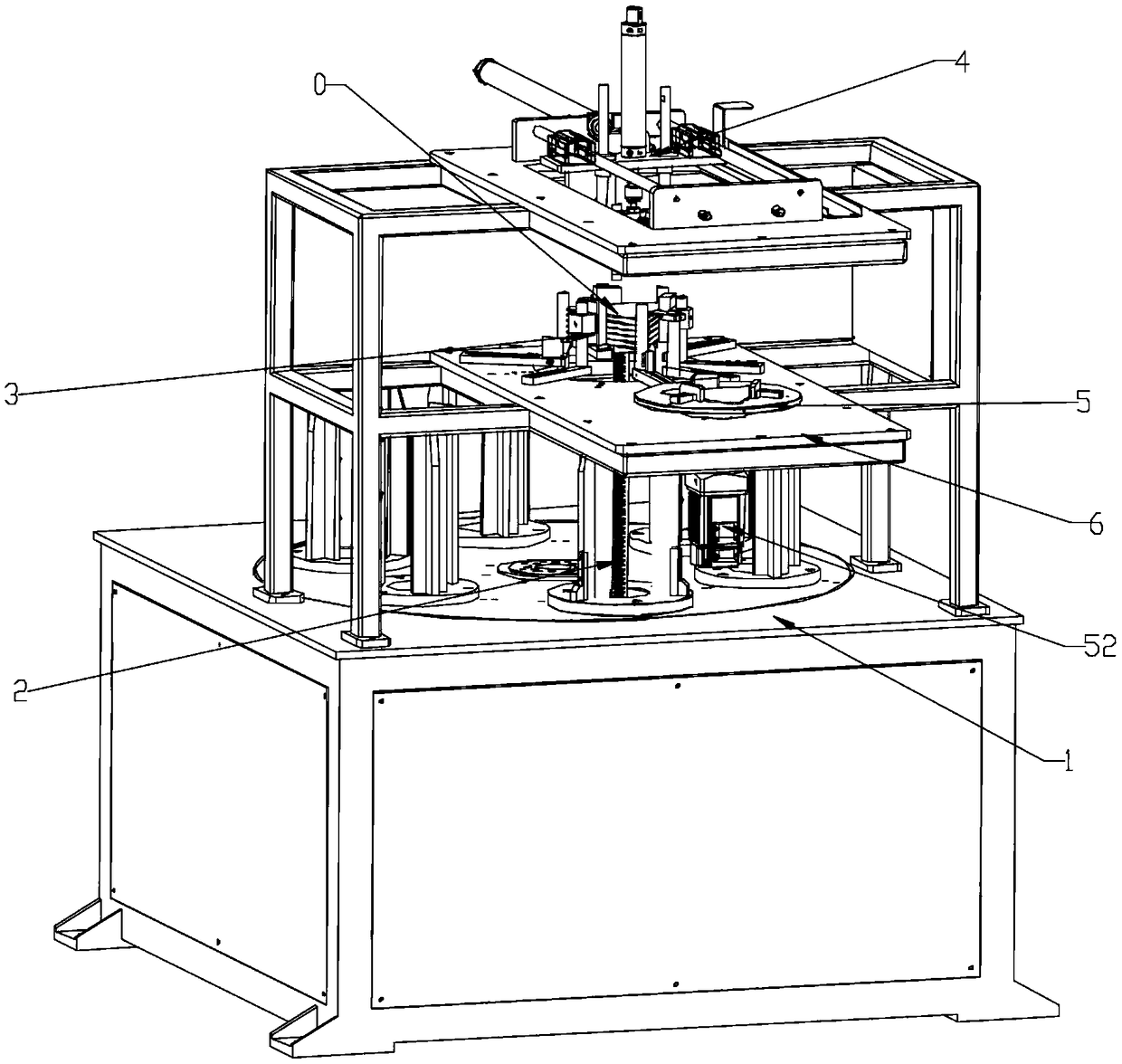

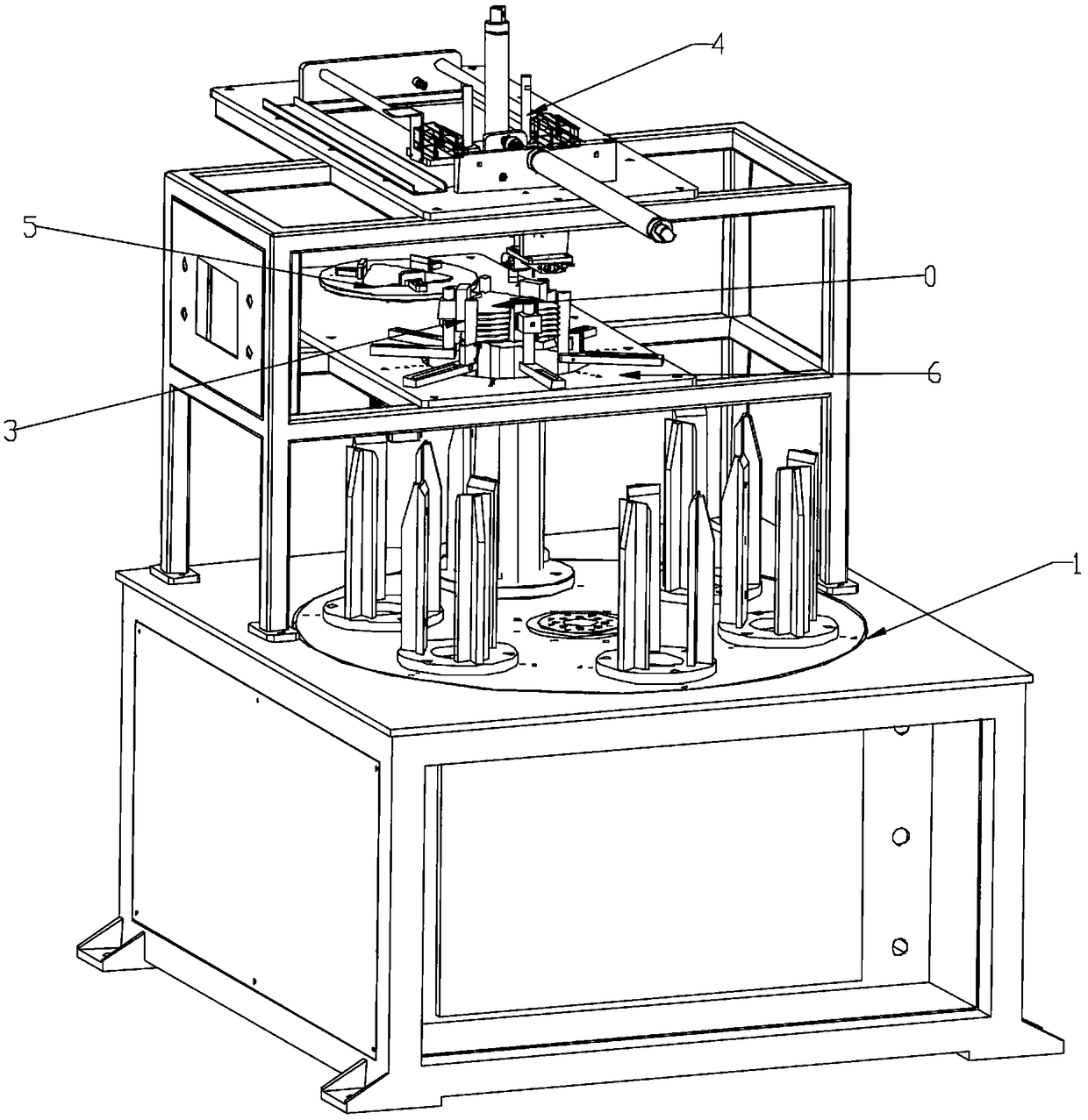

[0022] refer to figure 1 and figure 2 , the present invention provides an automatic transfer mechanism 5 for tripod blanks, which is applied to an automatic feeder for tripod blanks. Feeding also includes a loading mechanism 1, a pushing mechanism 2, a separation mechanism 3, a pick-up mechanism 4, a double-material detection mechanism 7 and a horizontally placed workbench 6.

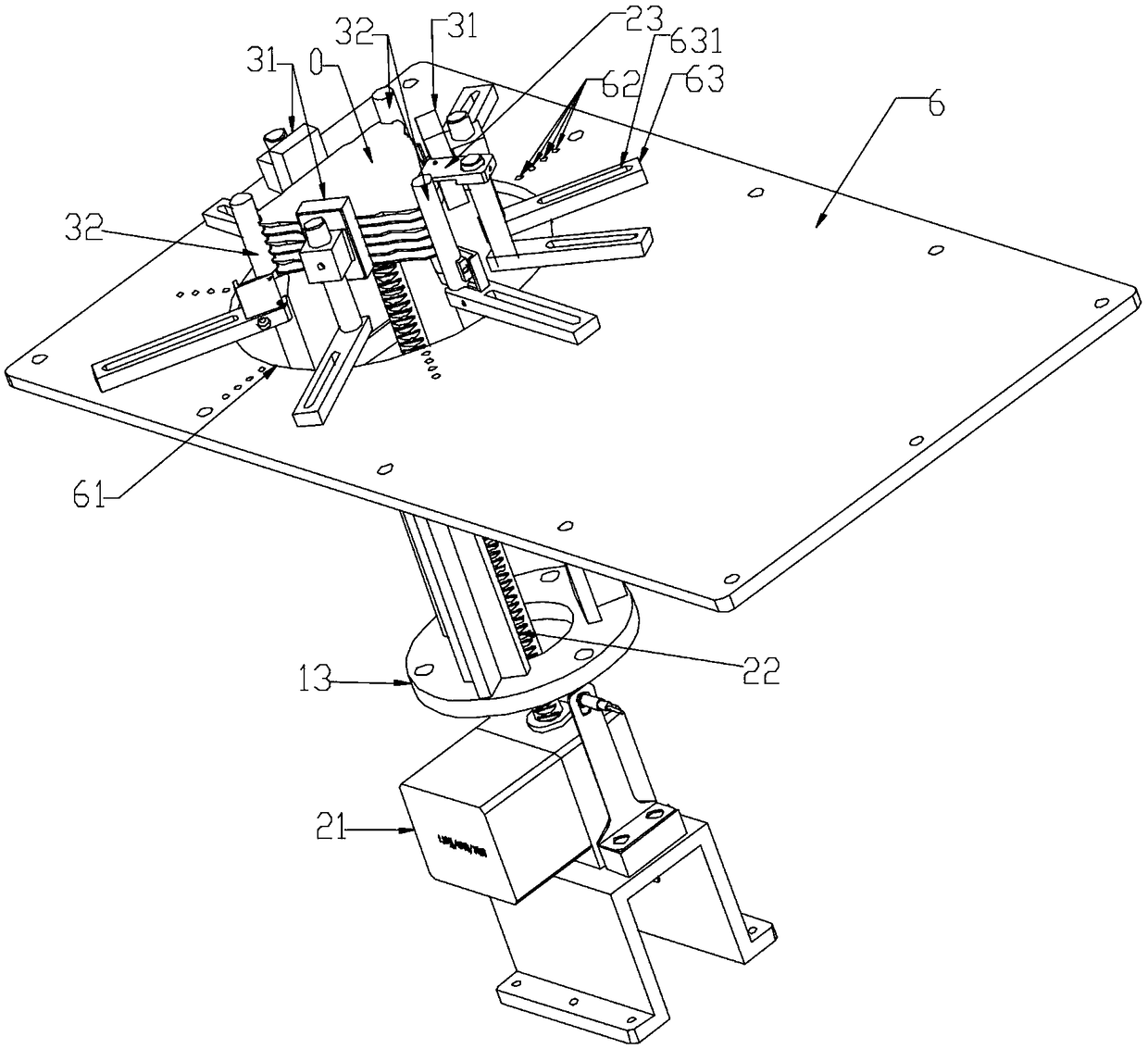

[0023] refer to figure 1 and image 3 , the workbench 6 is provided with a feed port 61, a number of positioning holes 62 equidistantly arranged around the feed port 61, and a predetermined number of fixed brackets 63, the fixed bracket 63 is provided with a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com