Efficient punching device for hardware thin plate

A technology for punching equipment and thin plates, which is applied in metal processing equipment, drilling/drilling equipment, boring/drilling, etc. It can solve problems that affect work efficiency and hinder the process of putting materials into it, and achieve good positioning effect. The effect of shortening the movement stroke and improving the effect of clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

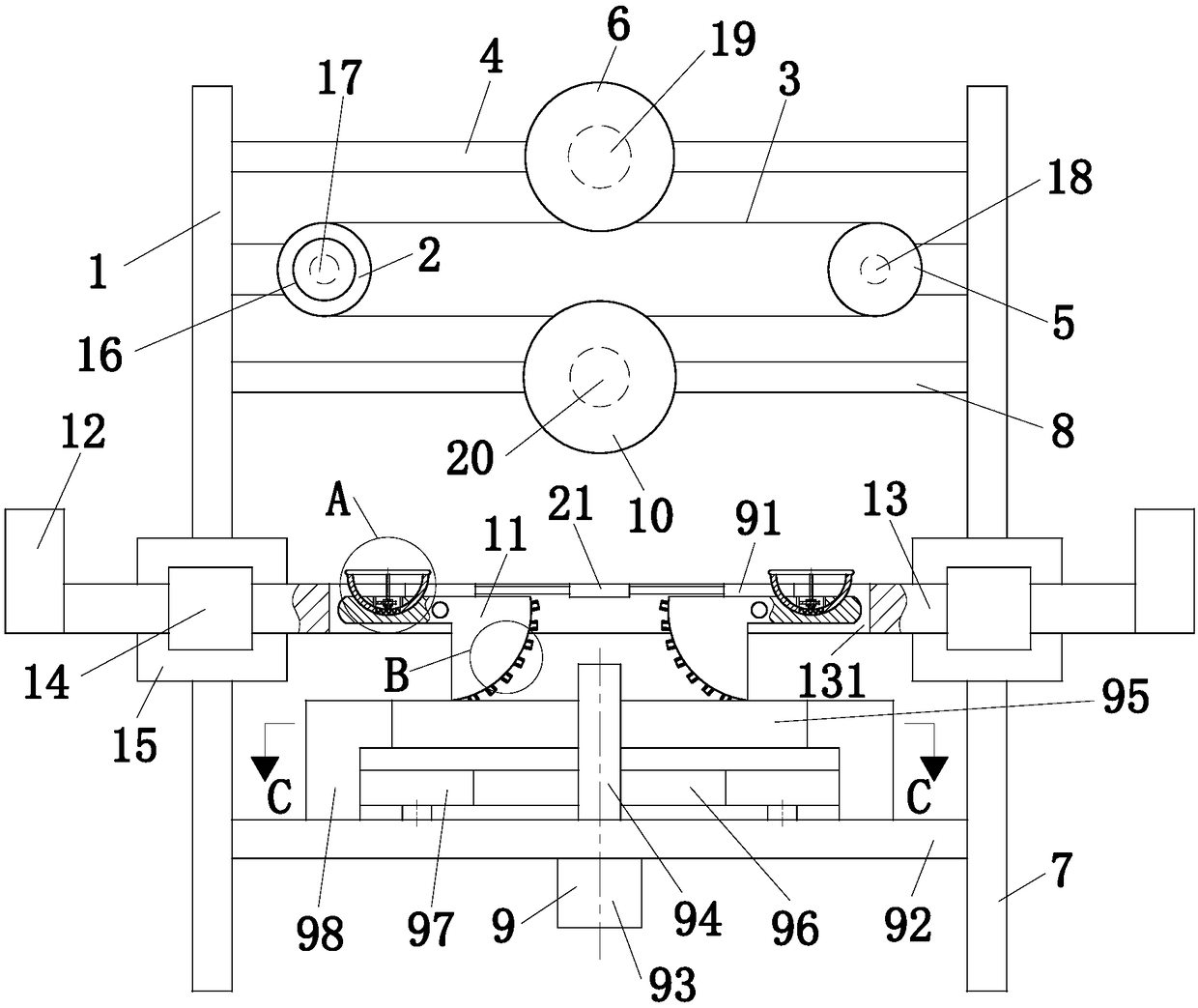

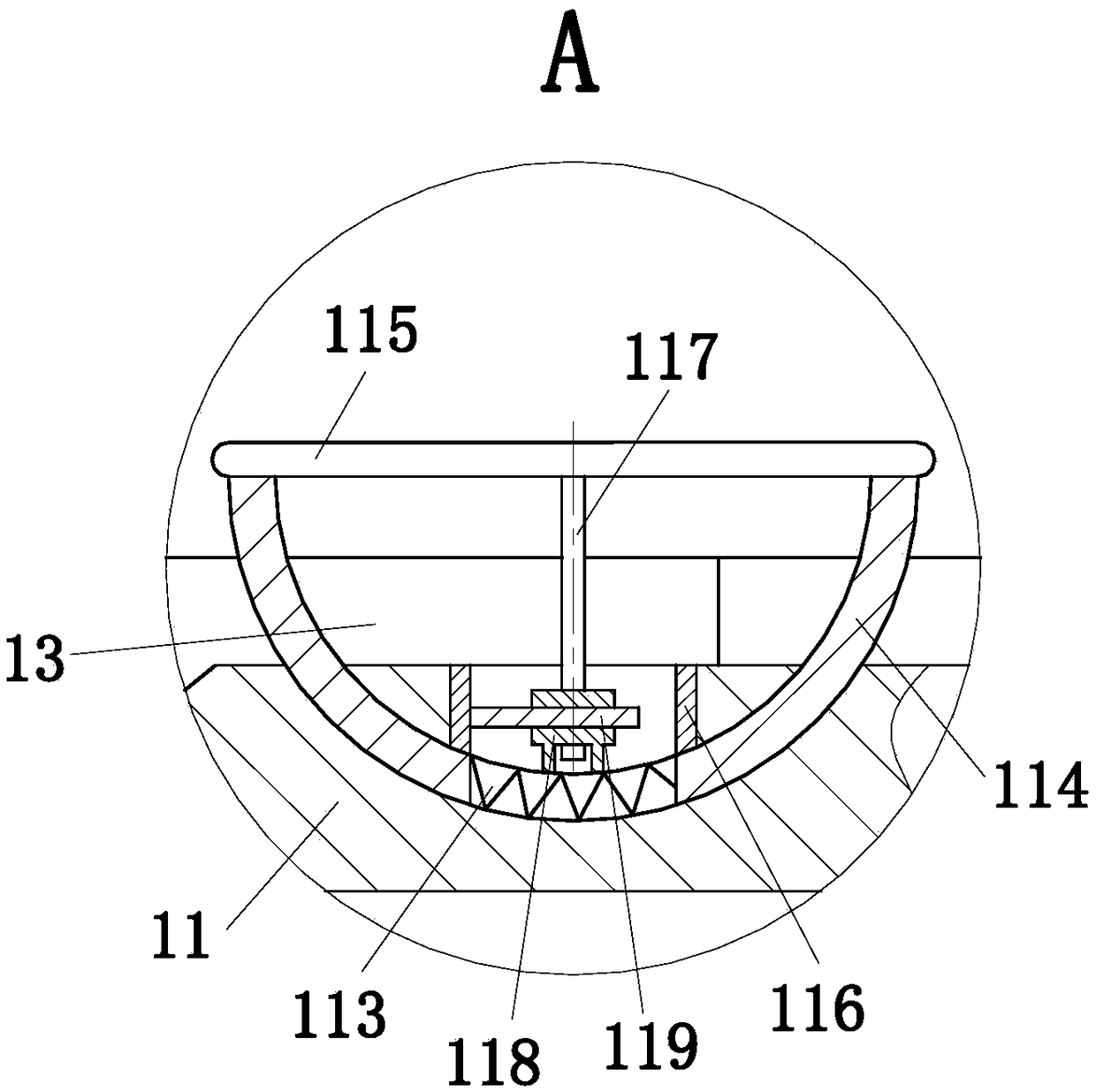

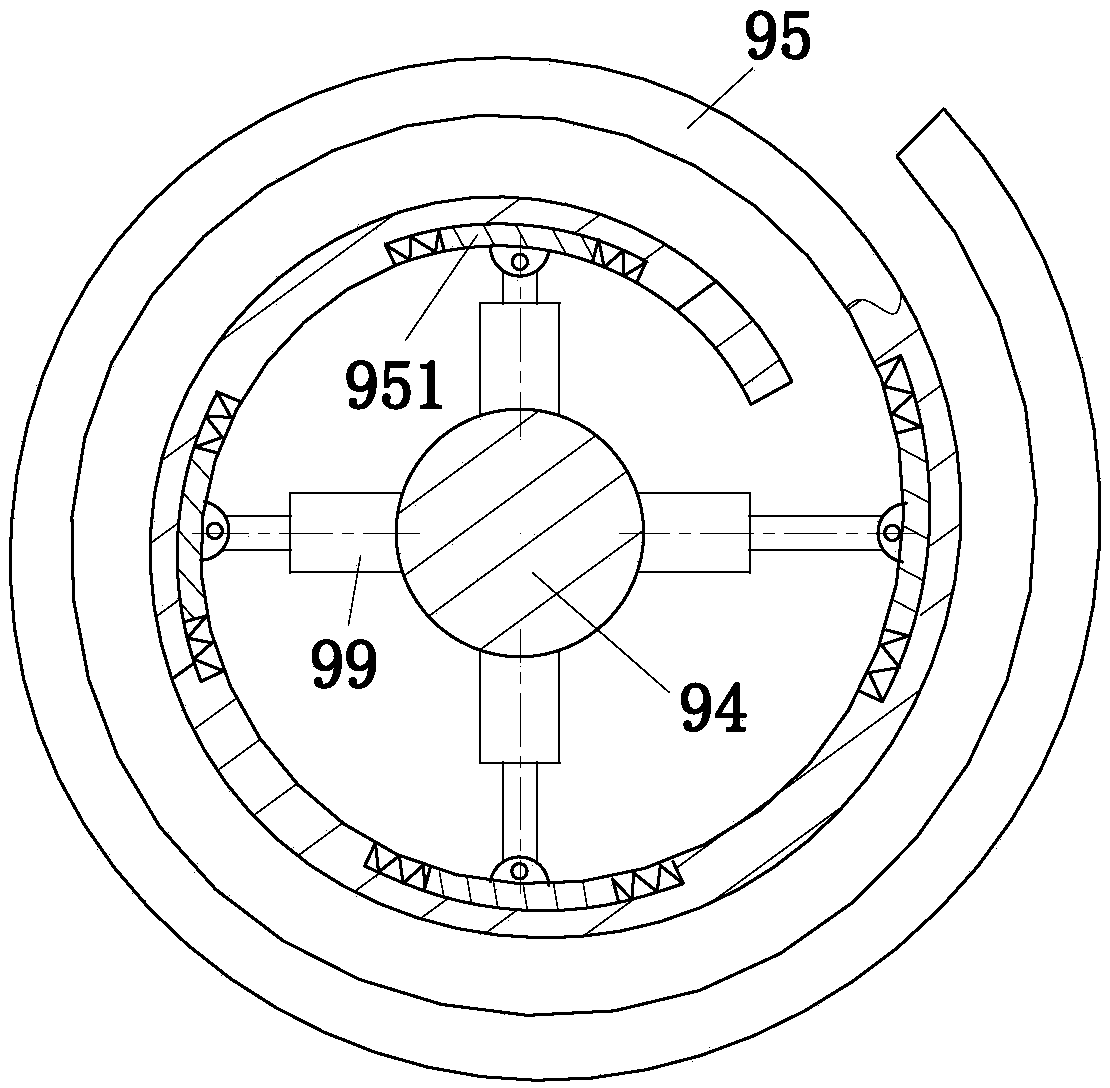

[0024] use Figure 1-Figure 7 A high-efficiency punching device for a metal sheet according to an embodiment of the present invention is described as follows.

[0025] Such as Figure 1-Figure 6As shown, a high-efficiency punching equipment for metal sheets according to the present invention includes a left frame 1, a first pulley 2, a flat belt 3, a first connecting rod 4, a second pulley 5, a third pulley 6, and a right frame 7 , the second connecting rod 8, the fourth pulley 10, the block 11, the push handle 12, the placement plate 13, the slide block 14, the slide rail 15, the power unit 9 and the reduction motor 16; Motor 16, reduction motor 16 rear side is connected with first belt pulley 2, and first belt pulley 2 rear side is connected with first drilling rod 17, and right frame 7 left middle part is connected with second belt pulley 5, and second belt pulley 5 rear side is connected with The second drilling rod 18, the first connecting rod 4 is connected between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com