Preparation method of sulfur-doped alkylated graphene material

A graphene and sulfur-doped technology, applied in graphene, petroleum industry, nano-carbon and other directions, can solve the problems of friction adhesion surface dispersion, unfavorable long-term use, discount of lubricating oil effect, etc., to improve interlayer agglomeration and deposition, The effect of solving uneven lubrication and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

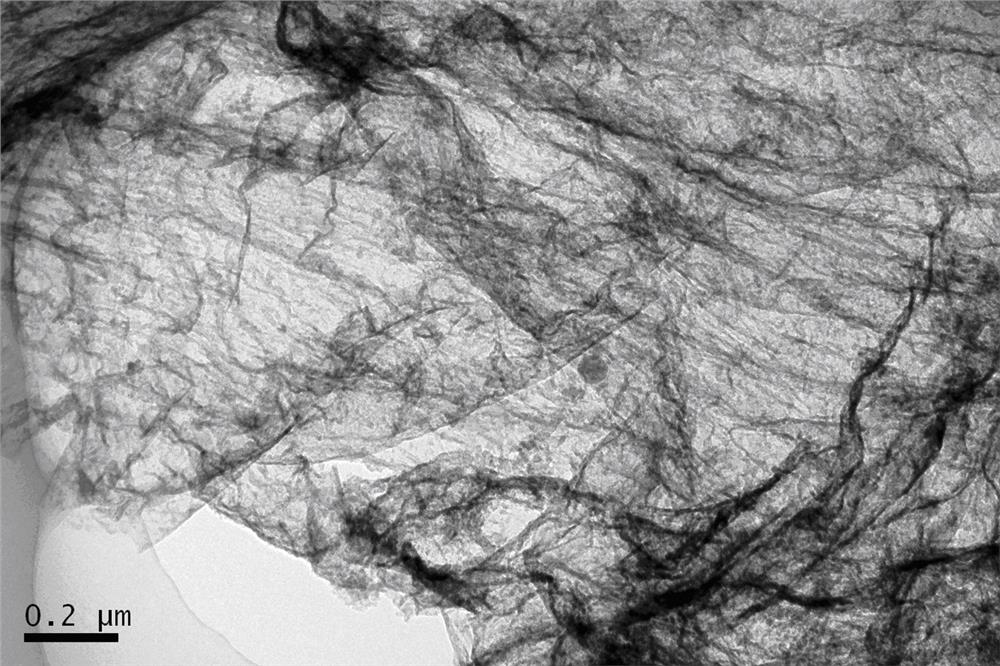

Image

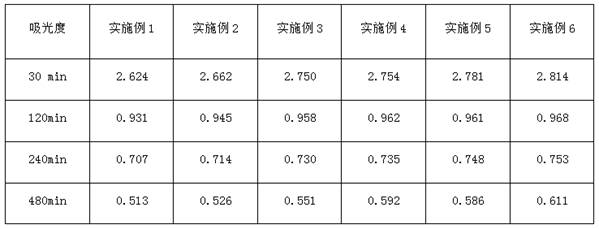

Examples

Embodiment 1

[0021] (1) Take 1 g of graphene powder (3500 mesh), add 46 ml of concentrated sulfuric acid (98%H 2 SO 4 ) and 0.5 g nitric acid (NaNO 3 ), at 35 o Stir for 2 min under heating in a water bath.

[0022] (2) Continue stirring the mixture in an ice bath to lower its temperature to 0 o C, add 3 g potassium permanganate (KMnO 4 ), and the initial temperature of the reaction was controlled at 20 o Within C, after the reaction is stable at 35 o C water bath heating condition was stirred for 24 h, and graphene oxide was obtained after centrifugal filtration.

[0023] (3) Take 100 mg of graphene oxide and disperse it in 5 ml of DMF, mix it evenly by ultrasonic, add 20 ml of thionyl chloride (SOCl 2 ) after vacuuming for 2 min to remove water, at 80 o Reflux for 24 h under the condition of heating in a water bath, and use a calcium chloride drying tube to remove the moisture in the gas.

[0024] (4) After centrifuging the reaction product of the previous step, take the lower l...

Embodiment 2

[0029] (1) Take 1 g of graphene powder (3500 mesh), add 46 ml of concentrated sulfuric acid (98%H 2 SO 4 ) and 0.5 g nitric acid (NaNO 3 ), at 35 o Stir for 2 min under heating in a water bath.

[0030] (2) Continue stirring the mixture in an ice bath to lower its temperature to 0 o C, add 3 g potassium permanganate (KMnO 4 ), and the initial temperature of the reaction was controlled at 20 o Within C, after the reaction is stable at 35 o C water bath heating condition was stirred for 24 h, and graphene oxide was obtained after centrifugal filtration.

[0031] (3) Take 100 mg of graphene oxide and disperse it in 5 ml of DMF, mix it evenly by ultrasonic, add 20 ml of thionyl chloride (SOCl 2 ) after vacuuming for 2 min to remove water, at 80 o Reflux for 24 h under the condition of heating in a water bath, and use a calcium chloride drying tube to remove the moisture in the gas.

[0032] (4) After centrifuging the reaction product of the previous step, take the lower l...

Embodiment 3

[0036] (1) Take 1 g of graphene powder (3500 mesh), add 46 ml of concentrated sulfuric acid (98%H 2 SO 4 ) and 0.5 g nitric acid (NaNO 3 ), at 35 o Stir for 2 min under heating in a water bath.

[0037] (2) Continue stirring the mixture in an ice bath to lower its temperature to 0 o C, add 3 g potassium permanganate (KMnO 4 ), and the initial temperature of the reaction was controlled at 20 o Within C, after the reaction is stable at 35 o C water bath heating condition was stirred for 24 h, and graphene oxide was obtained after centrifugal filtration.

[0038] (3) Take 100 mg of graphene oxide and disperse it in 5 ml of DMF, mix it evenly by ultrasonic, add 20 ml of thionyl chloride (SOCl 2 ) after vacuuming for 2 min to remove water, at 80 o Reflux for 24 h under the condition of heating in a water bath, and use a calcium chloride drying tube to remove the moisture in the gas.

[0039] (4) After centrifuging the reaction product of the previous step, take the lower l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com