Split type metal reflector with flexible mounting structure and angle adaptive adjustment method

A technology for metal mirrors and mounting structures, applied in installation, optics, instruments, etc., can solve the problems of difficulty in simultaneously ensuring the angle adjustment of metal mirrors, surface shape accuracy requirements, reducing mirror processing costs and angle adjustment, etc., to achieve simplification Angle adjustment link, easy processing and assembly, high connection rigidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

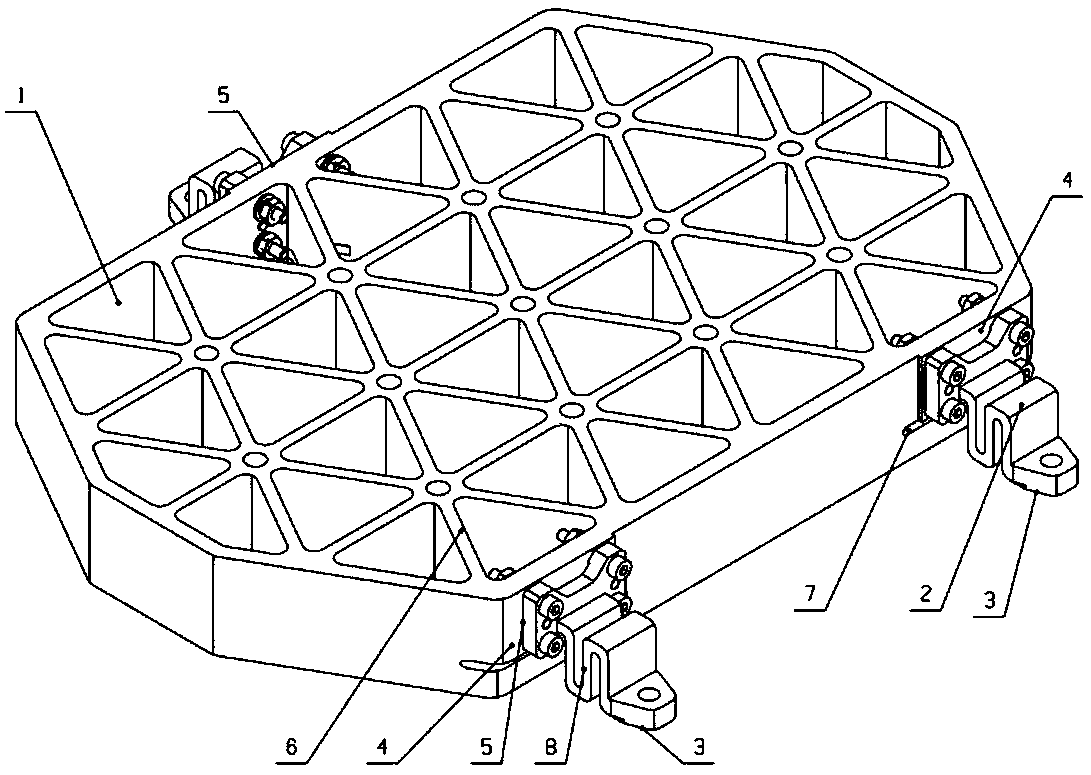

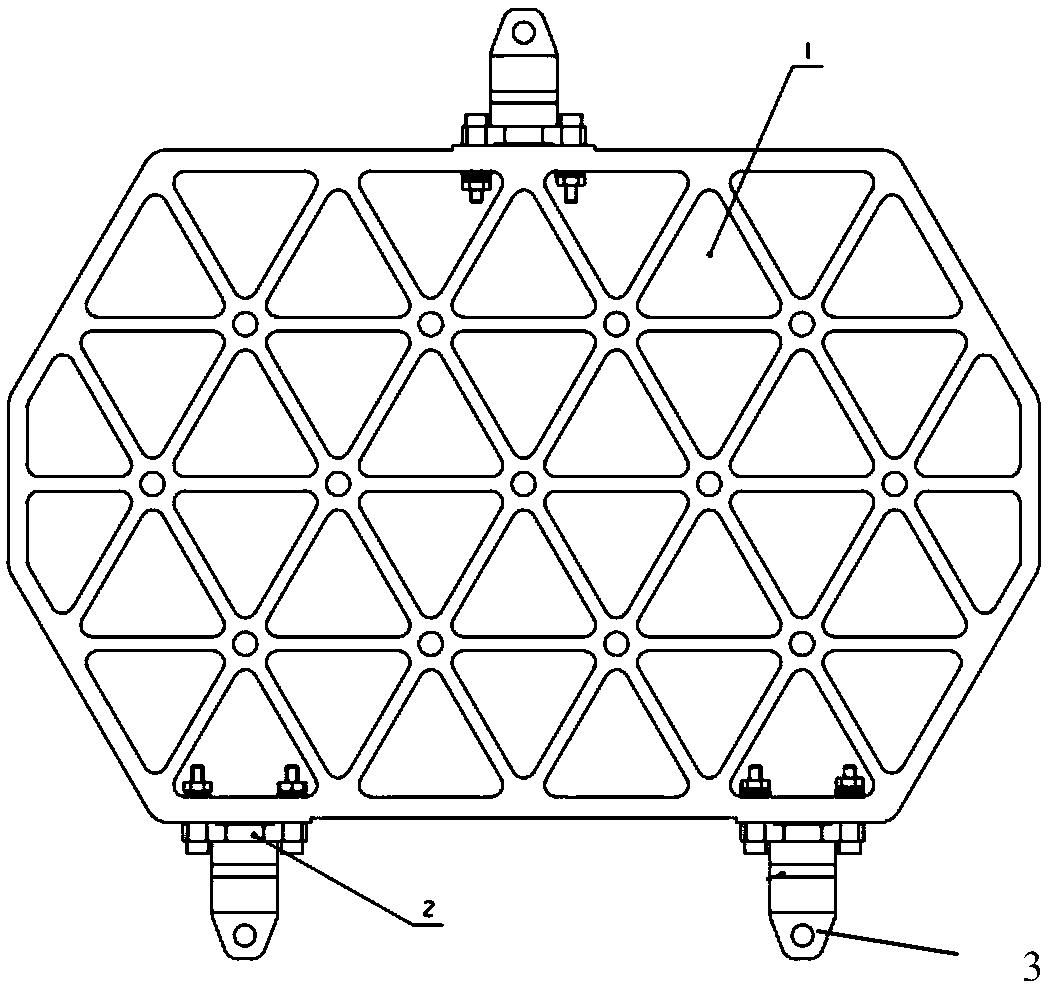

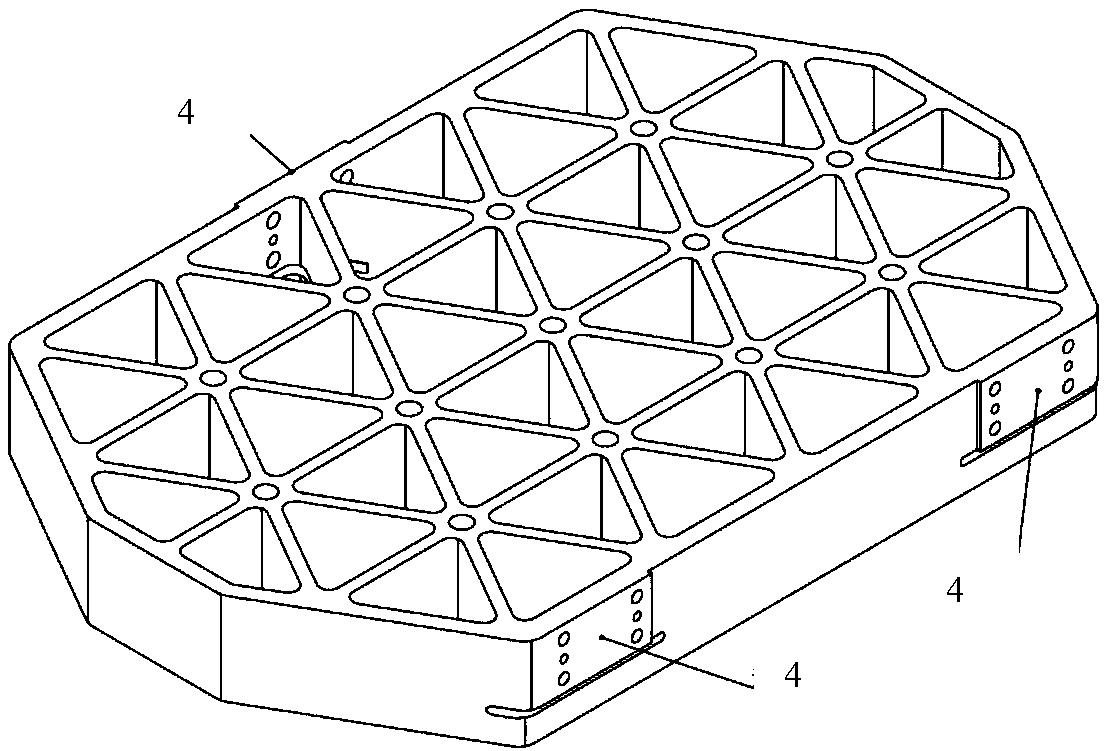

[0026] The invention provides a flexible installation structure of a metal reflector with self-adaptive angle adjustment, which includes a metal reflector and a flexible installation structure. The flexible installation structure has the characteristics of angle adjustment and flexible structure, and realizes angle adjustment and installation stress compensation functions. When adjusting the angle of the long axis of the mirror, it is not necessary to conduct angle research on the relevant mounting surface. It is only achieved by the relative rotation of the metal reflector and the mounting surface of the flexible mounting structure, which will not cause additional installation stress problems , and the process is simple.

[0027] The metal reflector separates the installation structure from the mirror body, and adopts a back triangular rib. In addition, in order...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com