Flat wire winding, motor stator, and motor

A flat wire winding and motor stator technology, which is applied to the shape/style/structure of winding and winding conductors, electrical components, etc., can solve problems such as skin effect and molding difficulties, and achieve saving winding materials, improving molding efficiency, folding Effect of Bending Resistance Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

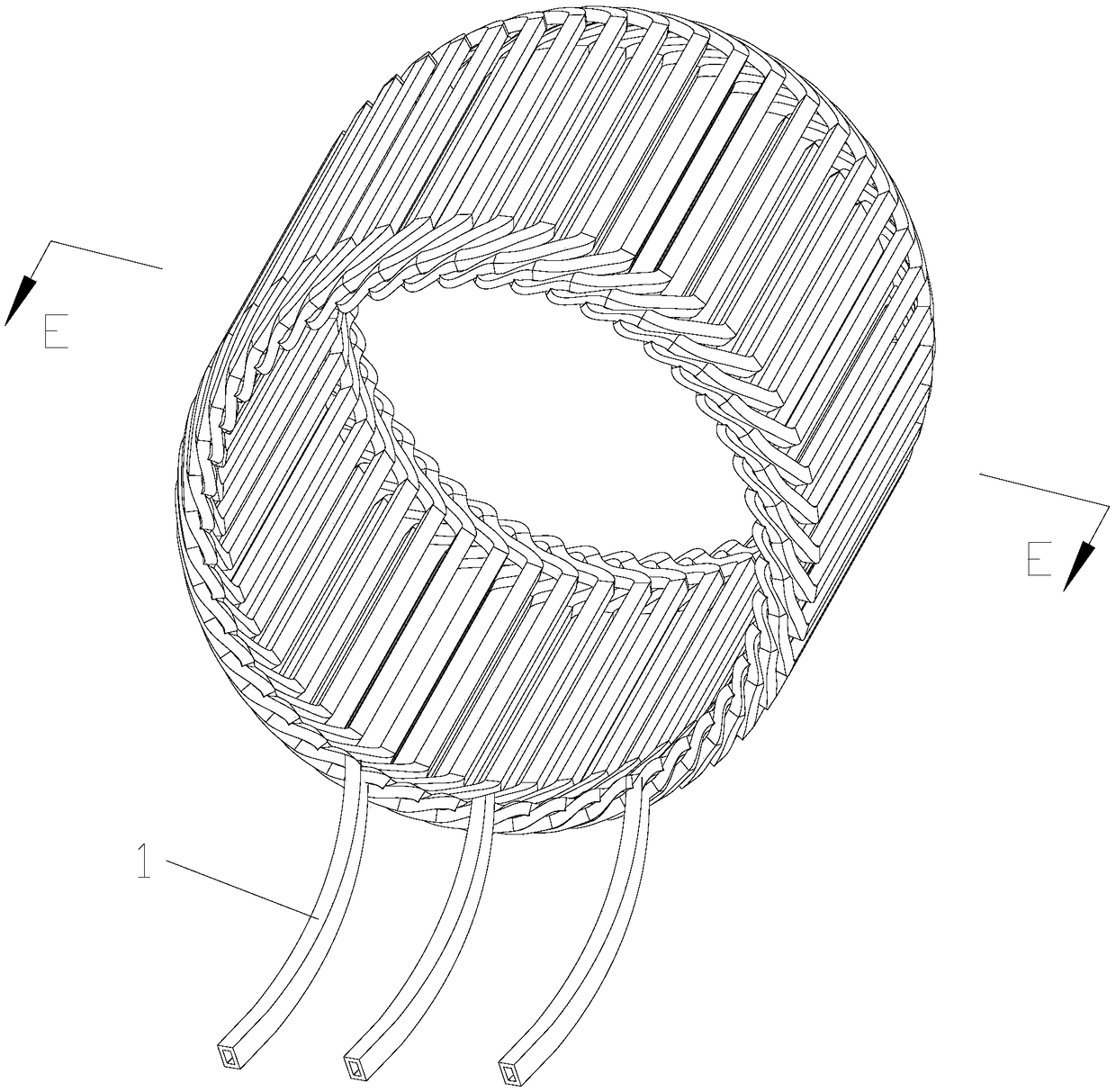

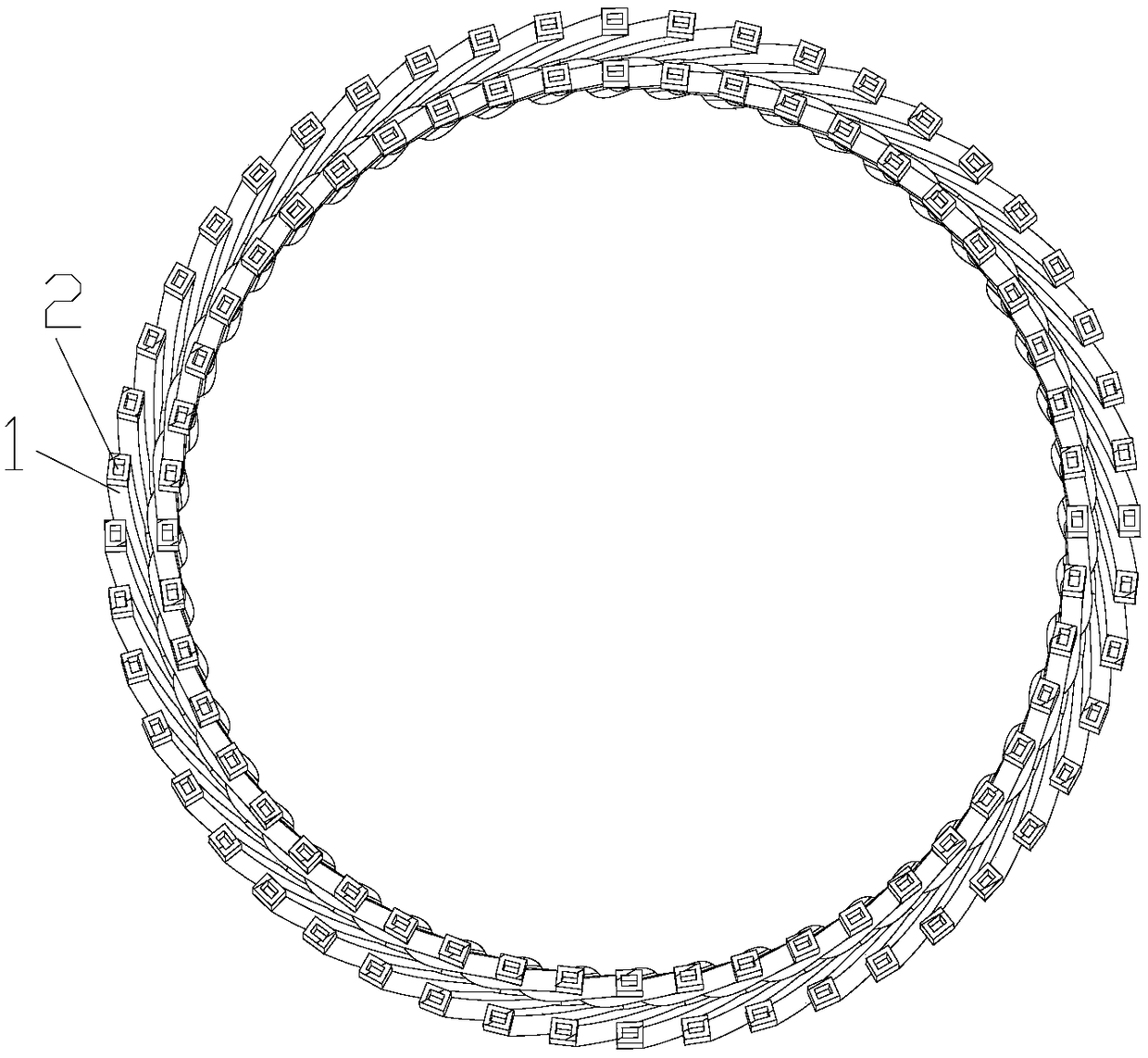

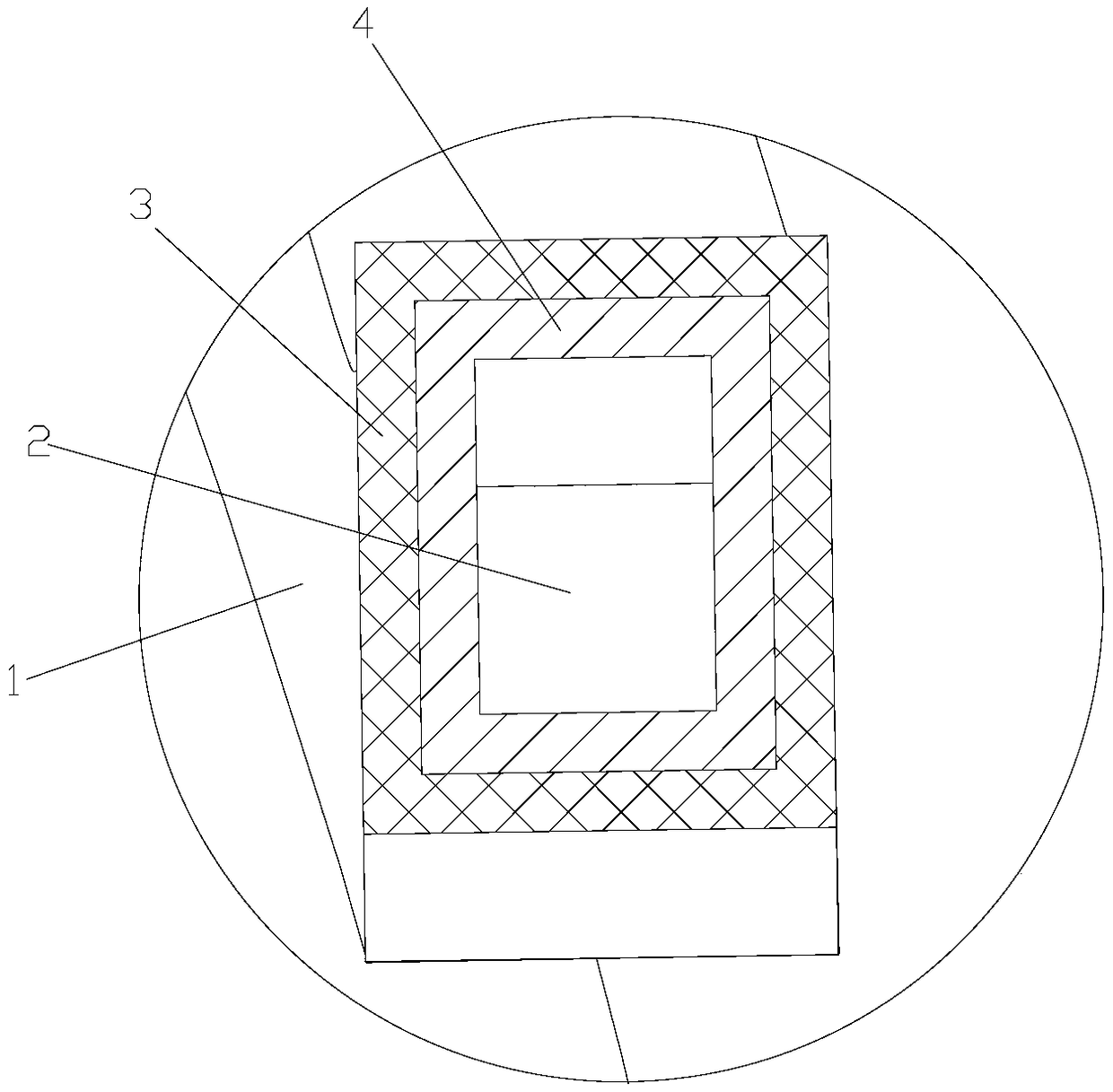

[0034] see in conjunction Figure 1 to Figure 10 As shown, the flat wire winding includes a flat wire unit 1 , and the flat wire unit 1 includes a flat wire hollow layer 2 .

[0035] After adopting the flat wire unit 1 including the flat wire hollow layer 2, a hollow flat wire winding can be formed, which can significantly reduce the skin effect generated when carrying a large current, save winding materials, and reduce winding costs. When bending flat wires, since the flat wire unit 1 is hollow, the bending resistance is reduced and it is easier to bend and form. The forming difficulty of the wire winding improves the forming efficiency of the flat wire winding.

[0036] Preferably, the flat wire hollow layer 2 extends along the length direction of the flat wire unit 1, and a larger length of the flat wire hollow layer 2 can be formed inside the flat wire unit 1, thereby reducing to a greater extent the noise generated when carrying a large current. skin effect. The flat w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com