Baffle mechanism for full-automatic pliers body continuous drilling-milling machine tool

A technology for processing machine tools and baffle mechanisms, applied in metal processing and other directions, can solve the problems of large mechanical wear and many lifting equipment, and achieve the effects of low maintenance cost, simple structure, and the realization of limit and avoidance functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

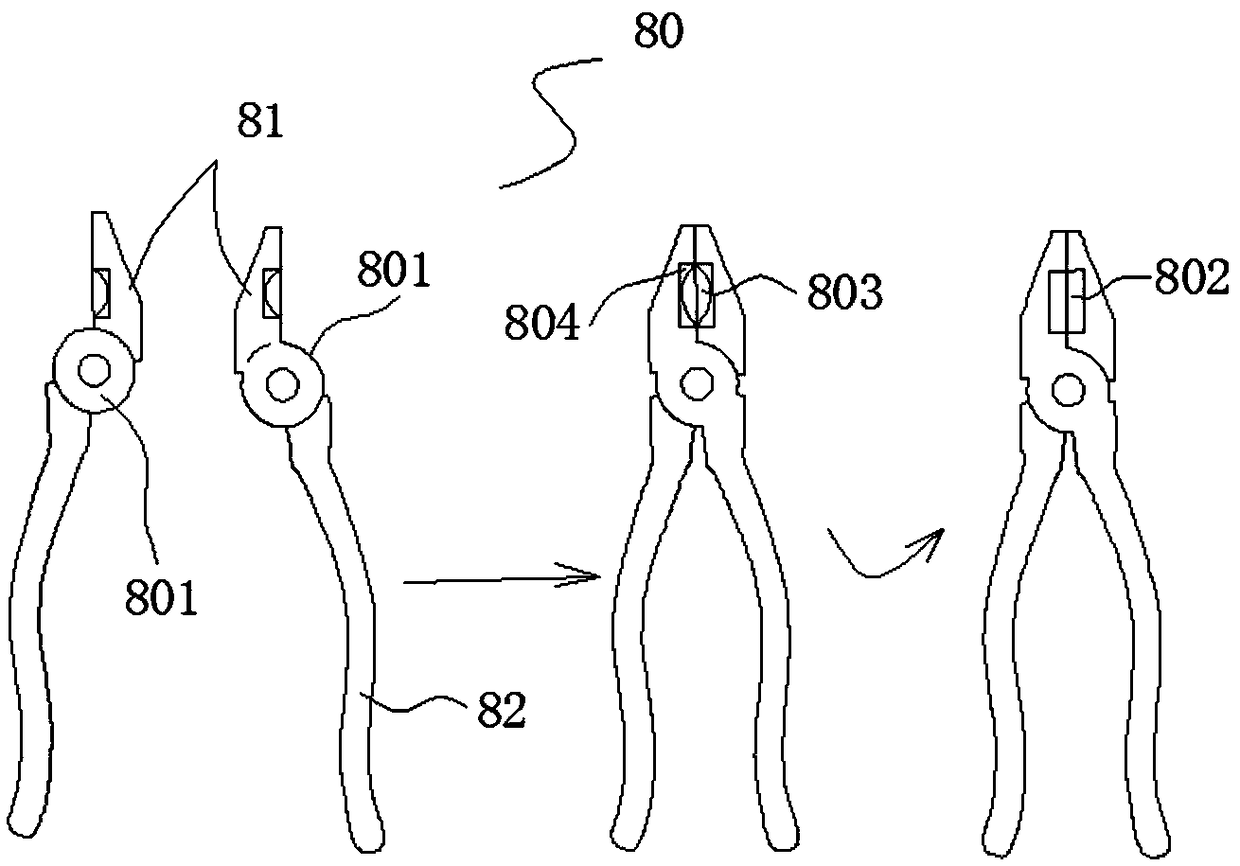

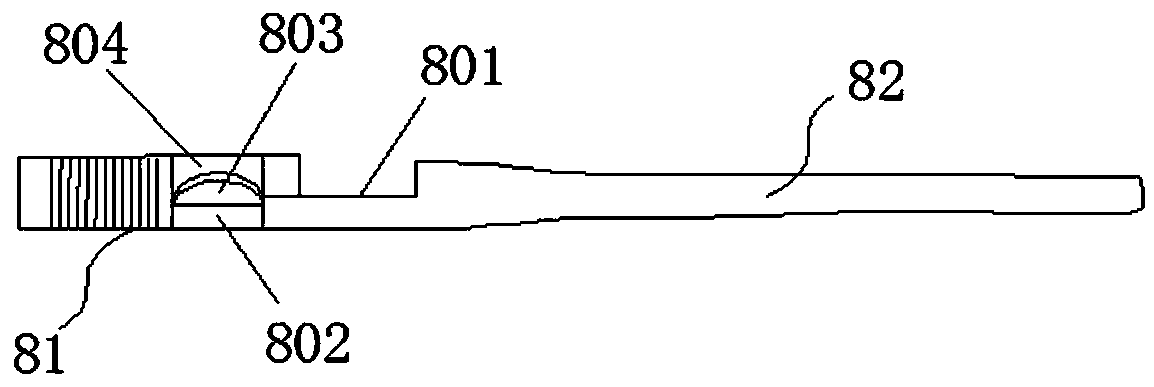

[0036] figure 1 It is a schematic diagram of the decomposition structure of the pliers body to be processed. figure 2 for figure 1 Schematic diagram of the front view structure of the middle left half of the forceps body. The processing equipment of the present invention is mainly the pliers structure shown in the milling figure, and it can also be realized for similar hardware milling.

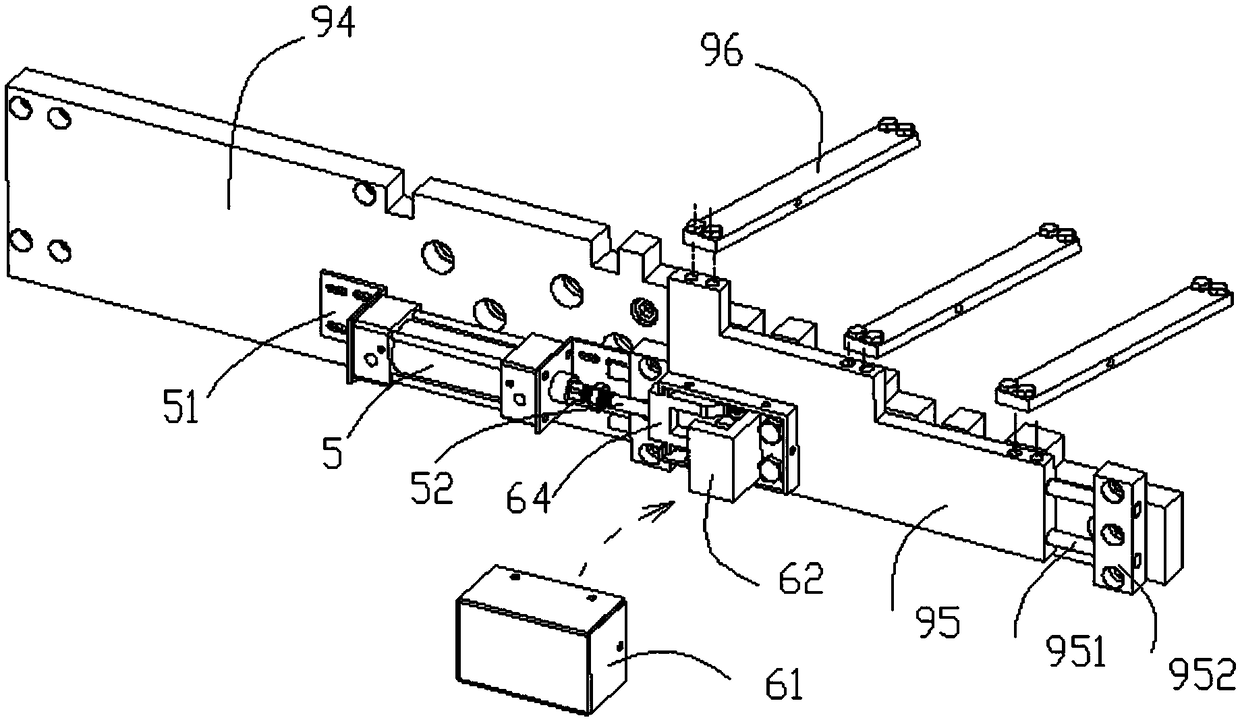

[0037] Such as Figure 3-Figure 7 Shown, the concrete structure of the present invention is: a kind of baffle plate mechanism that is used for automatic pliers body continuous drilling and milling processing ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com