Processing method for knitted threaded cuffs and necklines high in form retention and color fastness

A knitted thread, high color fastness technology, applied in knitting, dyeing, weft knitting and other directions, can solve the problems of affecting the appearance and service life of garments, restricting the application of knitted threaded cuffs, and deformation of threaded cuffs, etc., to achieve thread sag. Not easy to wrinkle, improve adhesion and tightening effect, improve the effect of stain resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

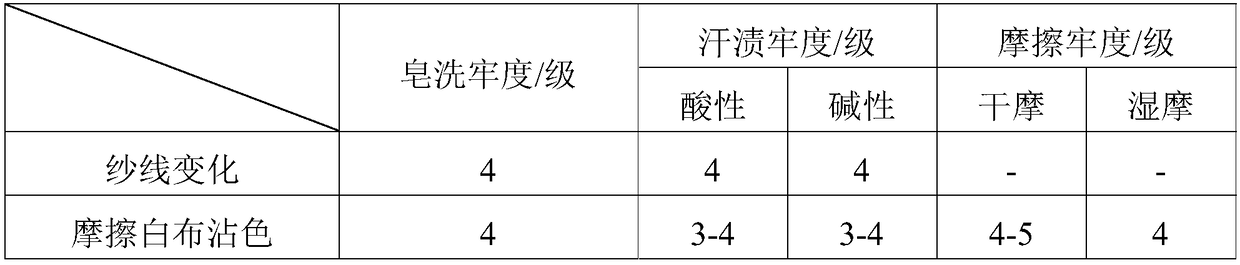

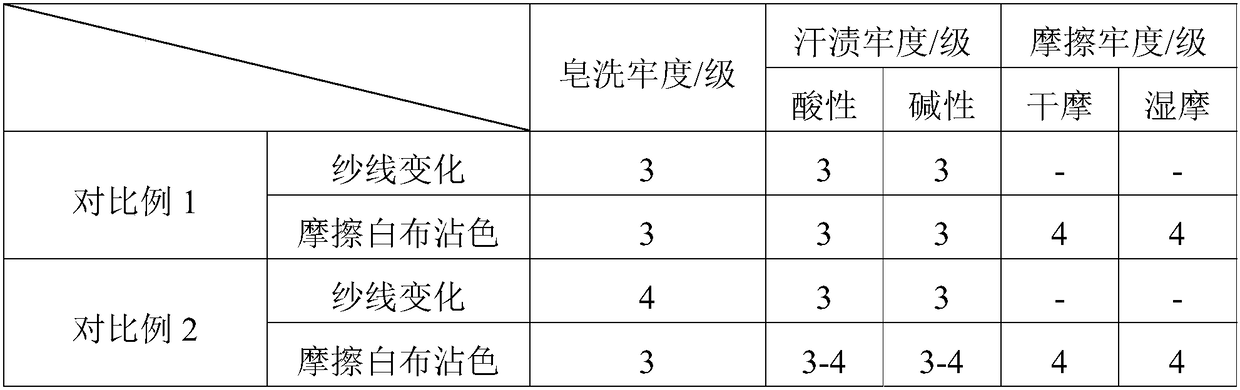

Examples

Embodiment

[0028] A method for processing knitted threaded cuffs and necklines with high retention and high color fastness. The spun silk and cotton blended yarns are sequentially scoured, bleached, dyed, and dried before weaving to obtain knitted threaded cuffs and necklines. Among them,

[0029] The scouring and bleaching process is as follows: take the spun silk cotton blended yarn and put it into the mixed solution containing chelating agent, stabilizer, penetrating agent, hydrogen peroxide, caustic soda and detergent, heat up the scouring and bleaching, and rinse. The content of chelating agent is 0.5g / L, the content of stabilizer is 1g / L, the content of penetrating agent is 1g / L, the content of hydrogen peroxide is 4g / L, the content of caustic soda is 1.5g / L, the content of cleaning agent 5g / L, the chelating agent is a fly ash chelating agent, the stabilizer is a PVC composite stabilizer, the penetrating agent is an alkali-resistant penetrating agent OEP-70, and the cleaning agent i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com