A two-stage electrophoresis process

A staged, electrophoresis technology, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., can solve problems such as asymmetrical shape of glass in the tank, poor glass in the batch tank, and unstable electrophoresis process, so as to reduce the cost of electrophoresis , The electrophoresis process is stable and the effect of reducing the defective rate of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The implementation of the present application will be described in detail below with reference to the accompanying drawings and examples, so as to fully understand and implement the implementation process of how the present application uses technical means to solve technical problems and achieve technical effects.

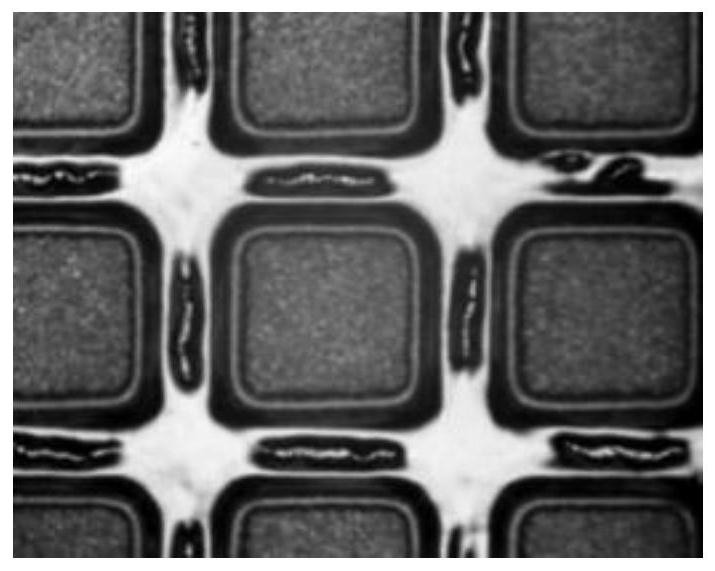

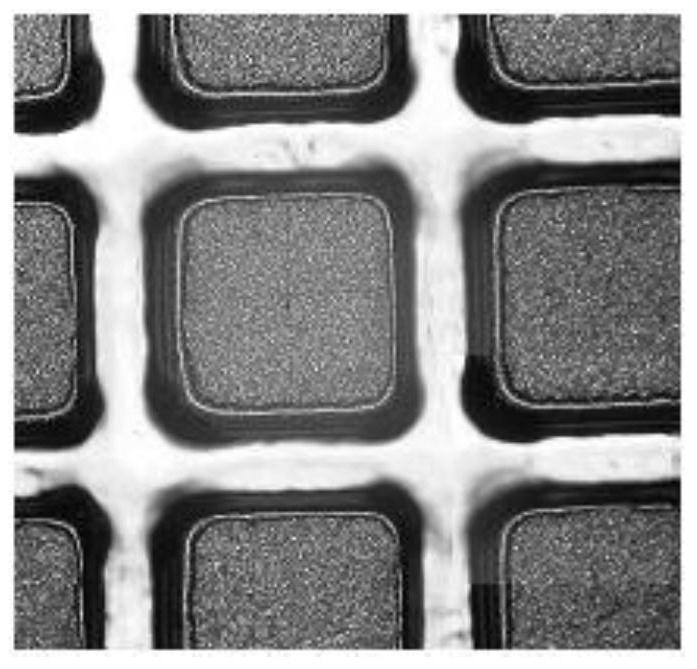

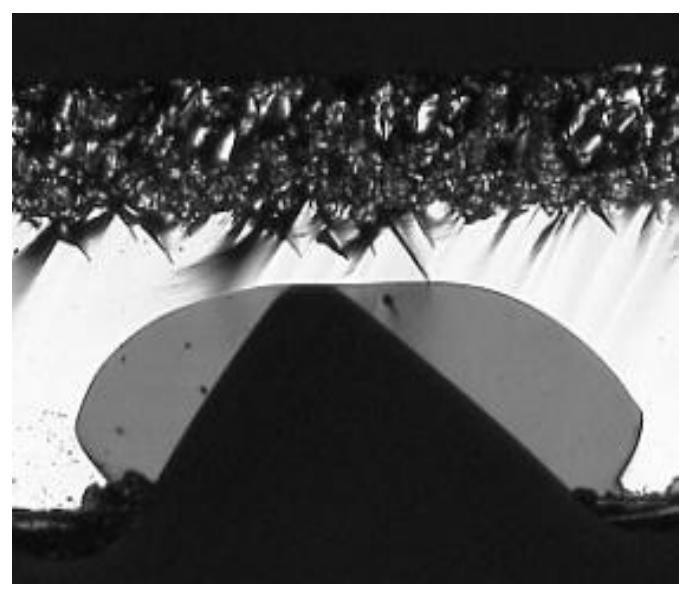

[0021] A two-stage electrophoresis process, the steps include: S1, using an electrophoretic solution with a low glass powder concentration to perform electrophoresis on a silicon wafer; S2, adding glass powder and an additive solution to the electrophoretic solution used in S1; S3, converting the silicon wafer through S1 The silicon wafer after electrophoresis is placed in the electrophoresis solution obtained in S2 for electrophoresis.

[0022] In step S1, that is, the first stage, the electrophoretic solution with low glass frit concentration, specifically, adding 60g-120g of glass frit and 2ml-7ml of additive solution to every 8L-9L of solvent. The solven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com