Method for producing partially defibrated fiber bundle, and method for producing fiber-reinforced resin molding material

A fiber reinforced resin and manufacturing method technology, which is applied in the direction of conveying filamentous materials, thin material processing, filament generation, etc. beams and other issues, to achieve the effect of reducing material costs, reliability balance, and manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

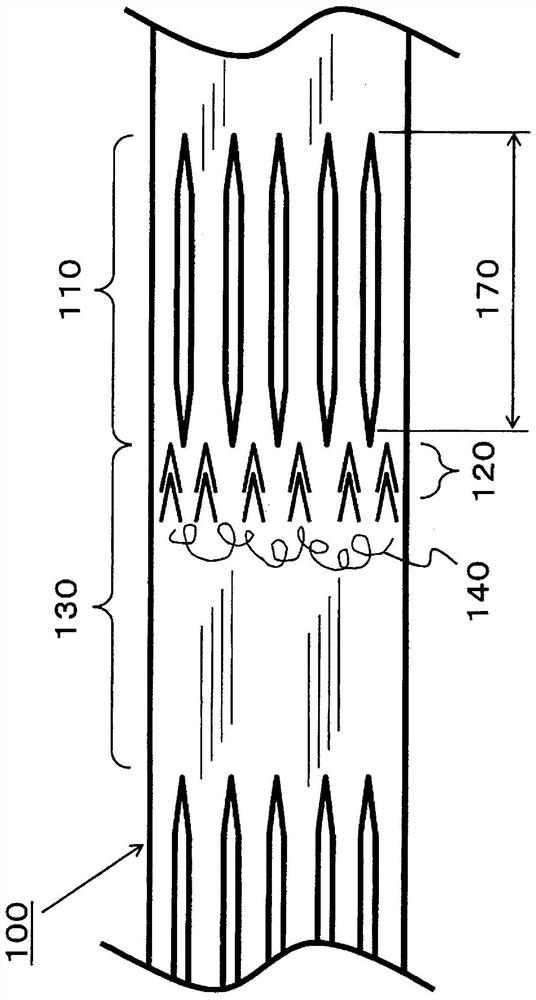

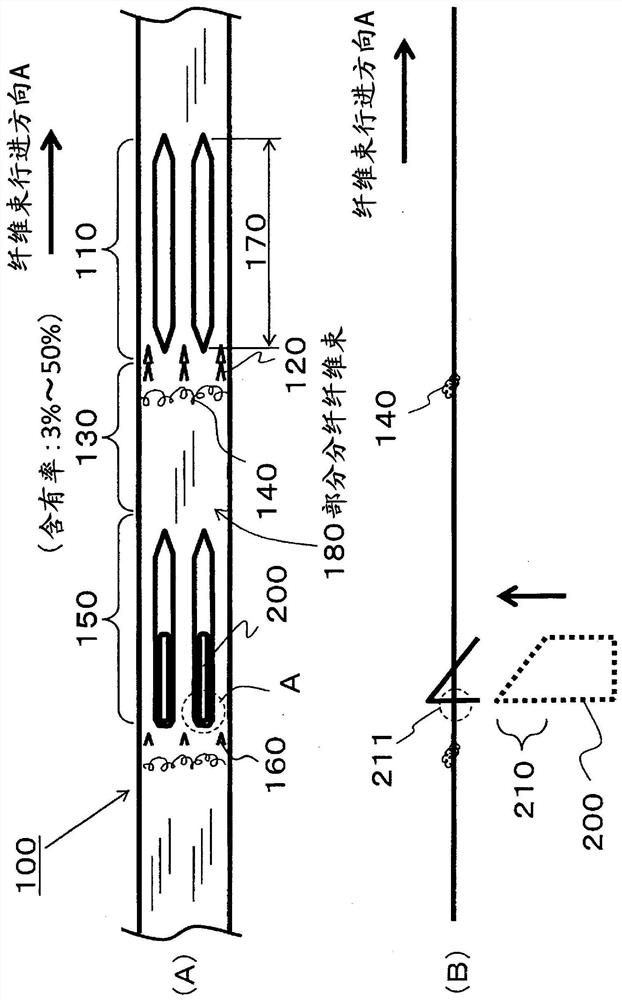

[0153] Using a winder, the fiber bundle [A-1] is rewinded at a constant speed of 10 m / min, and the vibration broadens the roller is passed from the axial vibration of 5 Hz, and then the widening process is performed from 20 mm wide width control roller. This is thus widened to broaden the fiber bundle of 20 mm. For the resulting broadening fiber bundle, the fiber treatment mechanism obtained in the following manner is prepared: the iron plate having a thickness of 0.2 mm, a width of 3 mm, a height of 20 mm, is a width direction of the reinforcing fiber bundle. The equivalent interval is set in parallel with a 5 mm equal interval. The framing mechanism is intermitted relative to the broadening fiber bundle, and wounds to the wound barrel, thereby obtaining a portion of the fiber bundle.

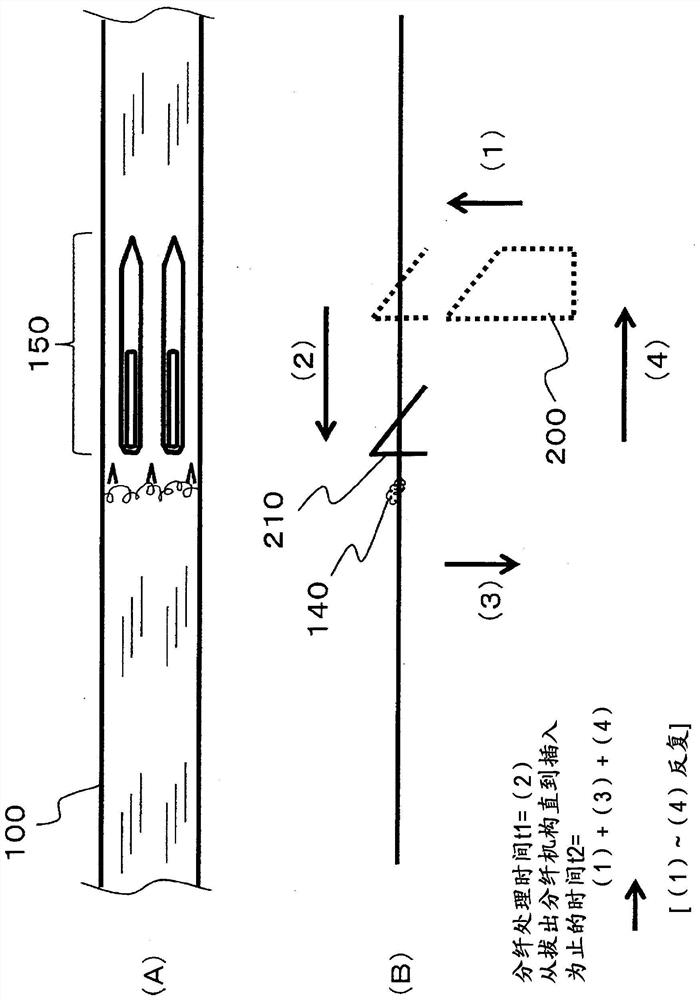

[0154] At this time, the framing process mechanism repeatedly performs the following operation with respect to the open-wide fiber bundle of 10 m / min to repeatedly perform the following operat...

Embodiment 2

[0160] Using a winder, the fiber bundle [A-2] is unfolded at a constant speed of 10 m / min, and the widening process is performed from the vibration broadening roller along the axial vibration of 10 Hz, and then the roller is passed from a width of 60 mm. This is thus widened to broaden the fiber bundle of 60 mm. For the resulting broadening fiber bundle, a framed treatment mechanism obtained by means of an equal interval of 3.5 mm in the width direction of the reinforcing fiber bundle in the width direction of the reinforcing fiber bundle is used in the width direction of the reinforcing shape. In addition to this, the bundle is operated in the same manner as in Example 1.

[0161] At this time, for the obtained portion of the fiber bundle, the fiber bundle is divided into 17 parts in the width direction in the width direction, and at least one end portion of the at least one fiber treatment section has monofilament. The complex accumulation portion accumulated in the complex po...

Embodiment 3

[0163] Anti-fiber bundle of fiber bundle [A-2] is used in accordance with the constant speed of 10 m / min, which is repeated, i.e., insertion of the fiber treatment mechanism for 1 second, generating a framed processing section, divided in 1 second. The fiber treatment mechanism is unplugged, inserted again, in addition to, in the same manner as in Example 2, evaluated. A series of evaluations obtained are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com