Flange for an electrical machine

A flange and chamber technology, applied in the field of motors, can solve problems such as the difficulty of effectively cooling the winding head, and achieve the effects of ensuring battery life, ensuring sealing, and increasing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

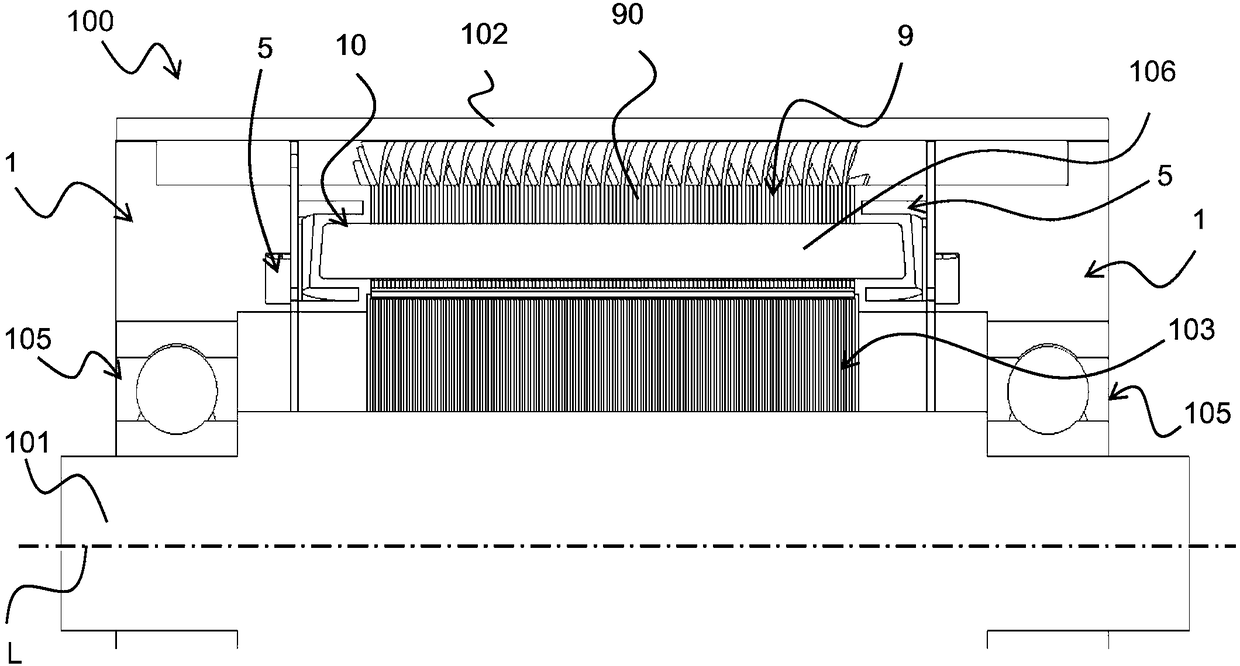

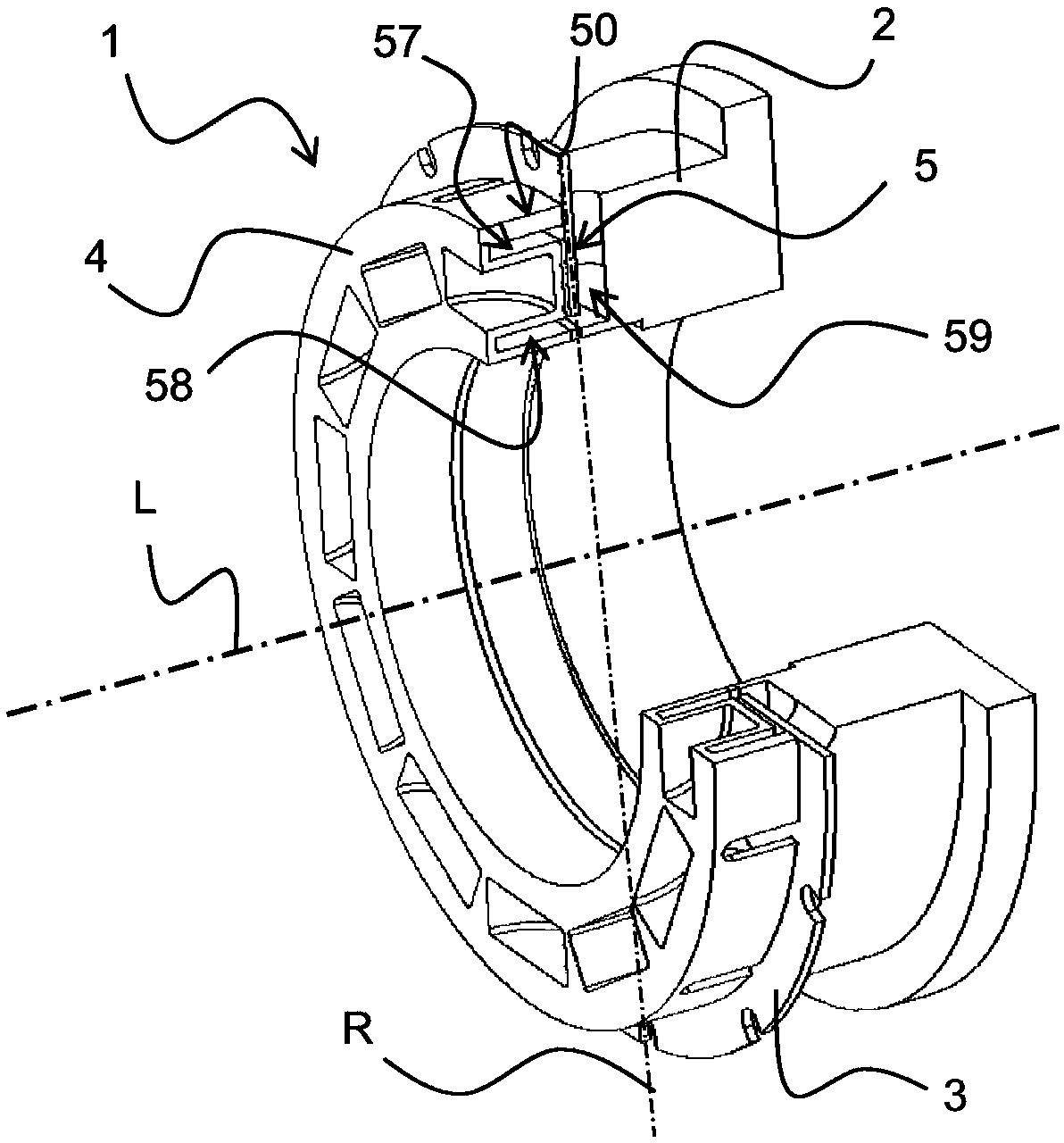

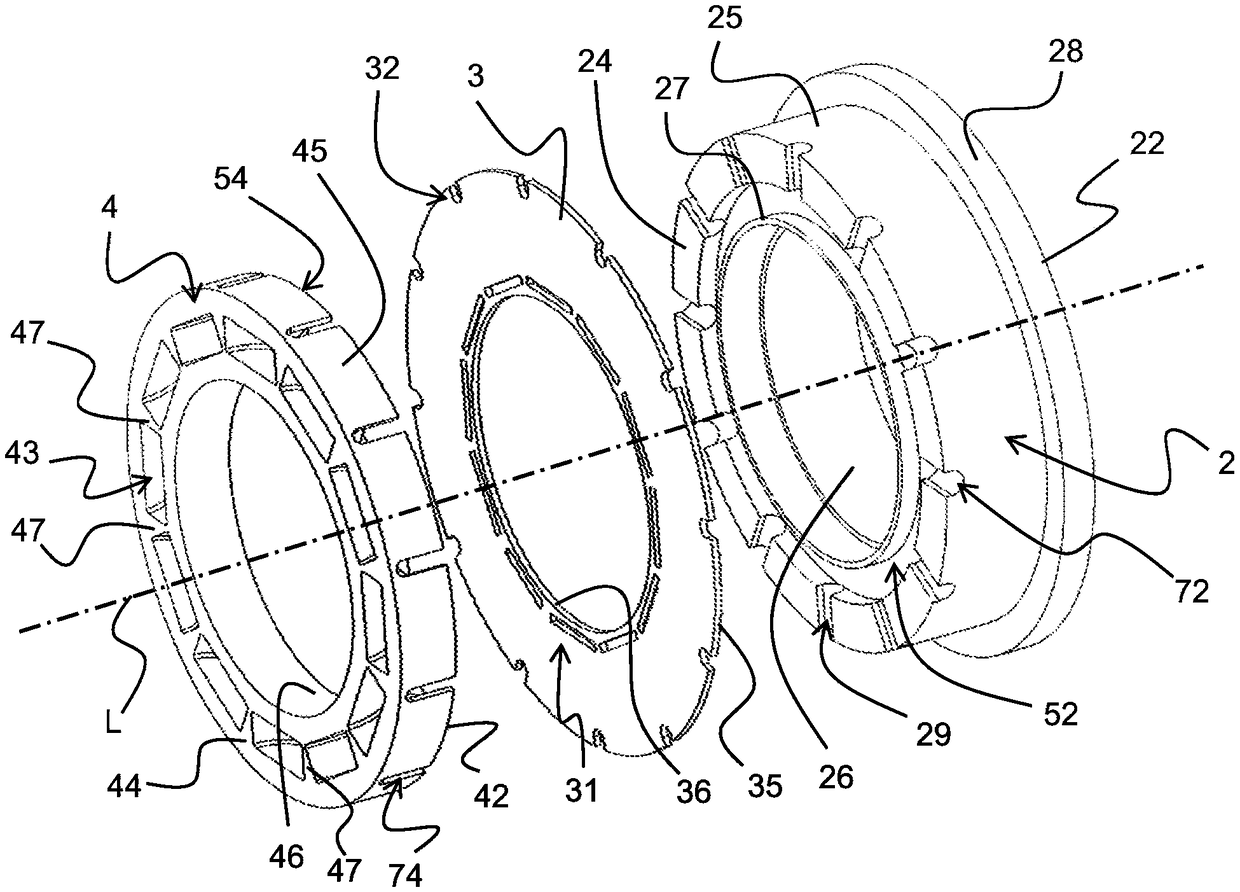

[0058] At the outset it is noted that the accompanying drawings show the invention in detail in order to realize it, said drawings can of course be used to better define the invention if necessary. Reference numerals remain the same from one figure to another.

[0059] In the following description, relative terms (eg "inner" or "outer") are defined relative to the flange and / or the longitudinal axis L of the motor. The term "inner" along this longitudinal axis means that the considered element is located inside or directed towards the inside of the machine, while the term "external" along the longitudinal axis means that the considered element is located outside or directed towards the outside of the machine. Relative terms (e.g. "inner", "outer") are defined relative to the radius R of the flange and / or motor, the "inner" concept is close to the center of the flange and / or motor, and the "outer" concept is away from the center, the center May for example be defined by a long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com