Impregnating device for preparation of mercury-free catalyst for acetylene hydrochlorination

A technology of acetylene hydrochlorination and impregnator, applied in the direction of physical/chemical process catalysts, catalyst activation/preparation, chemical instruments and methods, etc., can solve the problems of material loss, easy to cause accidents, uneven heating of materials, etc., and achieve improvement Anti-corrosion ability, prolong service life, good impregnation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

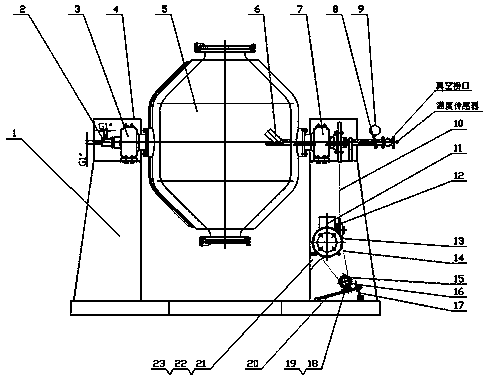

[0019] Double-cone cylinder (5) The inner shell of the cylinder is coated with a glass-lined layer, which can prevent the material from corroding the cylinder, and the inner wall of the cylinder is smooth, so that the material can be easily discharged. When working, put the material into the double-cone cylinder (5), close the hole cover of the feed port, turn on the vacuum pump, make the vacuum degree in the double-cone cylinder ≤0.1, press the work button, the motor (15) starts to work, and the The power is transmitted to the reducer (11) by the triangular tape (14), and the chain (10) is transmitted to the vacuum shaft, thereby driving the double-cone cylinder to start rotating. After the impregnator starts to rotate, the valve is opened to allow steam to enter the impregnation cylinder In the heating layer between the jacket and the jacket, the heat is contacted by the inner wall of the double-cone cylinder and the wet material, and the steam generated during the impregnati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com