A kind of tin/al-based material composite powder and its laser 3D printing forming method

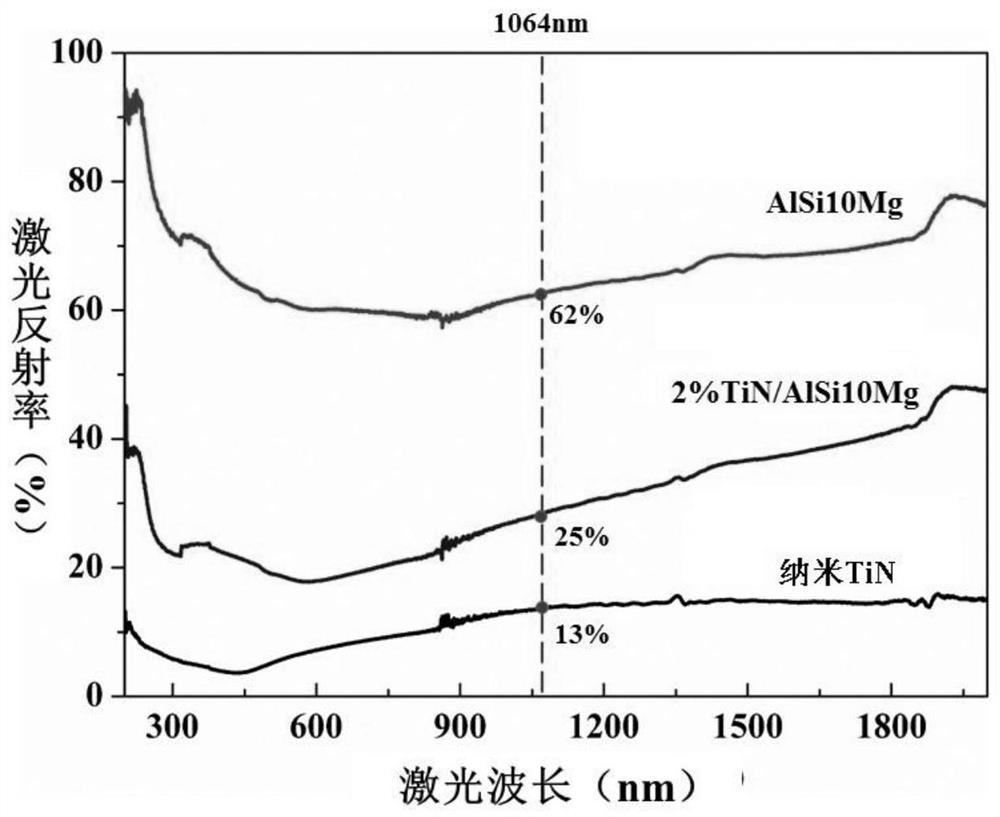

A composite powder and 3D printing technology, applied in the field of aluminum matrix composite materials, can solve the problems of cumbersome preparation process and destroy the shape of powder, and achieve the effects of simple preparation process, improved absorption capacity, and improved printing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

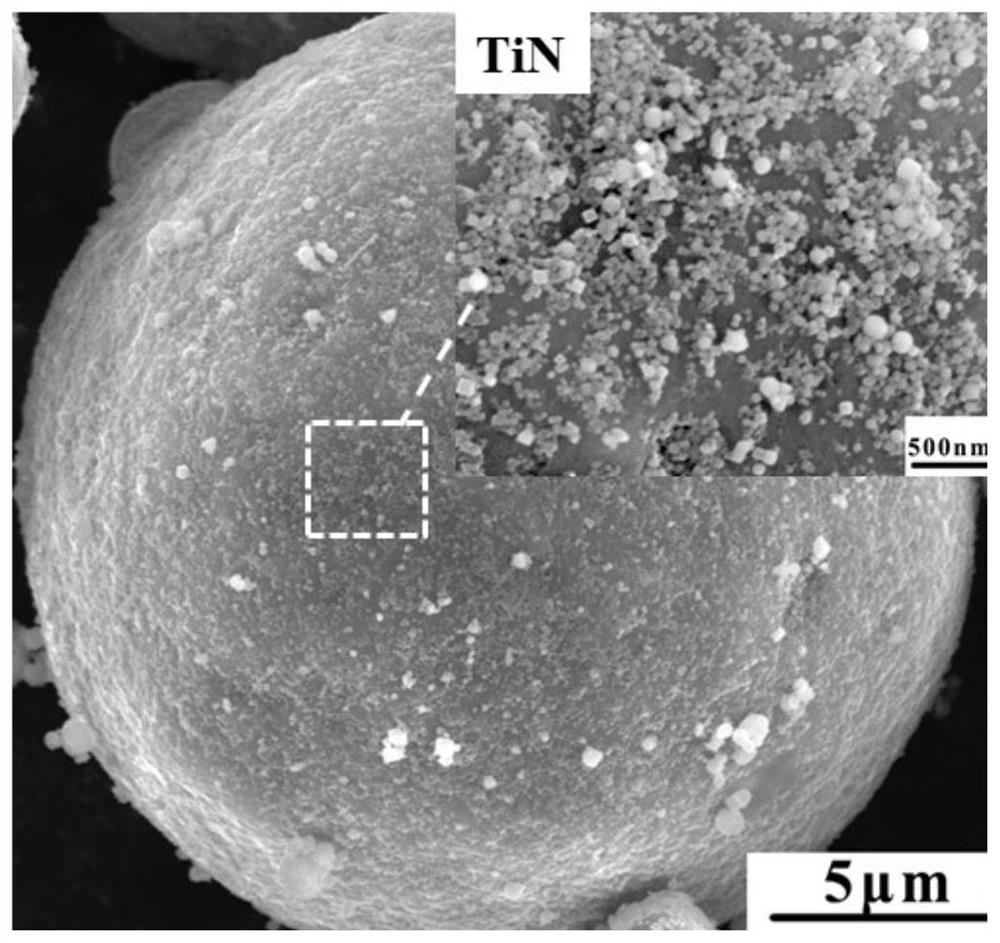

[0036] (1) The matrix of the composite material is selected as nearly spherical AlSi10Mg powder with a purity of 99.9%, and the particle size of the powder is 15-50 μm. The reinforcing phase is nano-spherical TiN powder with a purity of 99.9%, and its particle size is 10-100nm. The percentages of the two powder mass fractions are: AlSi10Mg 99%, TiN 1%.

[0037] (2) Add the above powders in sequence according to the method of equal increments, that is, first put 1wt% TiN and 1wt% AlSi10Mg powders into an ultrasonic vibrator and vibrate and disperse for 3min, the vibration frequency is 20KHz, and the mode is continuous. Add deoxidizer and desiccant at the same time. Then continue to add 2% AlSi10Mg and mix and disperse with the powder added for the first time, and the time length is 3mim. And so on, until all the powders of the required quality are initially mixed.

[0038] (3) Put the preliminarily mixed composite powder into a V-type mixer and mix for 12 hours.

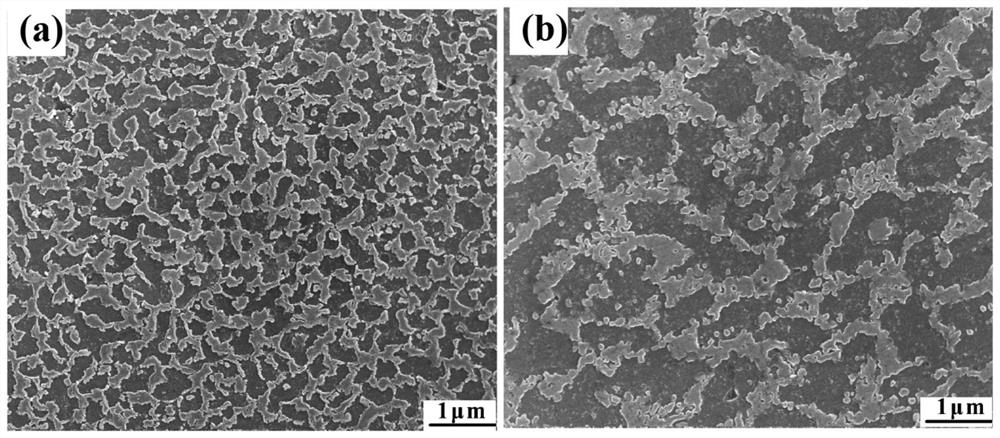

[0039](4)...

Embodiment 2

[0043] (1) The matrix of the composite material is selected as nearly spherical AlSi10Mg powder with a purity of 99.9%, and the particle size of the powder is 15-50 μm. The reinforcing phase is nano-spherical TiN powder with a purity of 99.9%, and its particle size is 10-100nm. Wherein the percentage of powder mass fraction is: AlSi10Mg 98%, TiN 2%.

[0044] (2) Add the above powders in sequence according to the method of equal increments, that is, first put 2wt% TiN and 2wt% AlSi10Mg powders into an ultrasonic vibrator to vibrate and disperse for 5min, the vibration frequency is 30KHz, and the mode is continuous. Add deoxidizer and desiccant at the same time. Then continue to add 4% AlSi10Mg and mix with the powder added for the first time, and the time length is 5mim. And so on, until all the powders of the required quality are initially mixed.

[0045] (3) Put the preliminarily mixed composite powder into a V-type mixer and mix for 10 hours.

[0046] (4) Take out the mi...

Embodiment 3

[0054] (1) The matrix of the composite material is selected as nearly spherical AlSi10Mg powder with a purity of 99.9%, and the particle size of the powder is 15-50 μm. The reinforcing phase is nano-spherical TiN powder with a purity of 99.9%, and its particle size is 10-100nm. The percentage of powder mass fraction is: AlSi10Mg 90% TiN 10%.

[0055] (2) Add the above powders in sequence according to the method of equal increments, that is, first put 10wt% TiN and 10wt% AlSi10Mg powders into an ultrasonic vibrator to vibrate and disperse for 5min, the vibration frequency is 25KHz, and the mode is pulse. Add deoxidizer and desiccant at the same time. Then continue to add 20% AlSi10Mg and mix with the powder added for the first time, and the time length is 5mim. And so on, until all the powders of the required quality are initially mixed.

[0056] (3) Put the preliminarily mixed composite powder into a V-type mixer and mix for 15 hours.

[0057] (4) Take out the mixed compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com