Board cutting-off machine

A cutting machine and wood board technology, which is applied to sawing components, sawing equipment, wood processing appliances, etc., can solve the problems of cutting machines without protective devices, machines without fixed distance devices, and harsh working environments, so as to ensure life and health. , The effect of preventing splashing everywhere and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

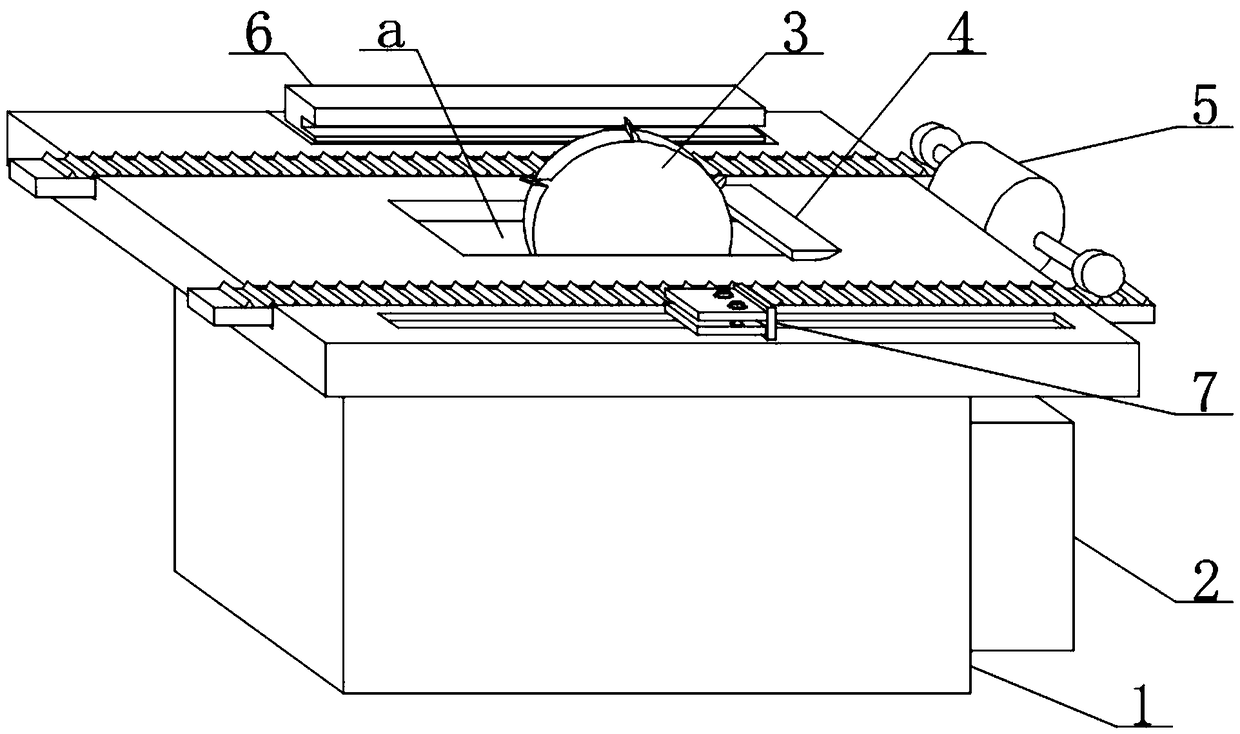

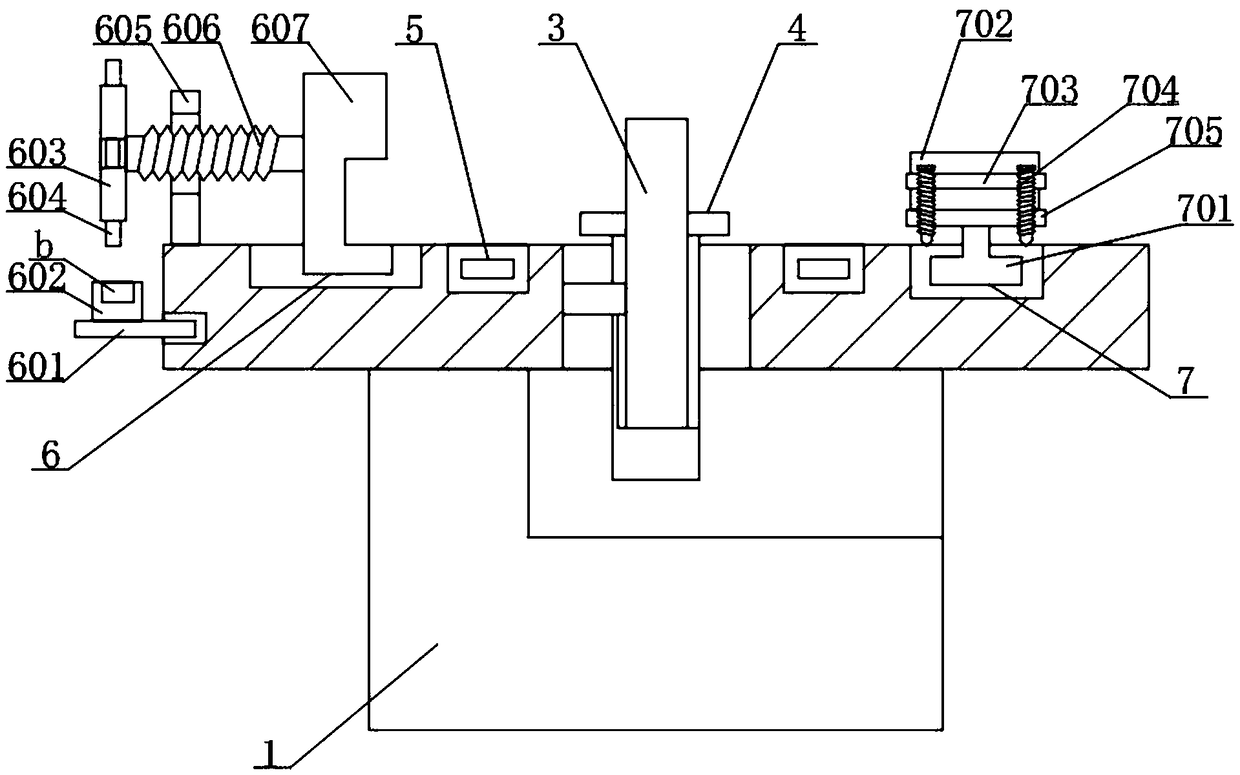

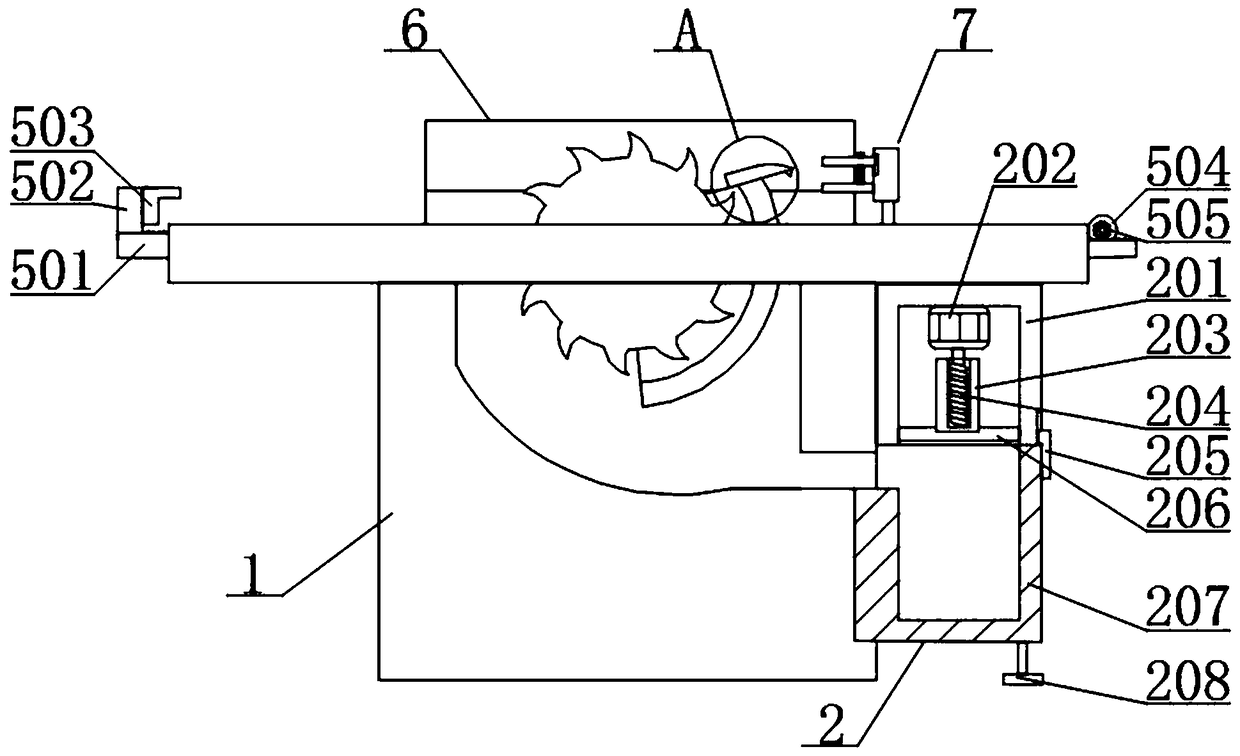

[0027] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , the present invention provides a technical solution:

[0028]A wood cutting machine, comprising a wood cutting machine 1, a collecting device 2, a saw blade 3 and a protective device 4, the right end of the wood cutting machine 1 is fixedly connected with a collecting device 2, and the collecting device 2 includes a protective shell 201, a three-phase motor 202, The push rod 203 and the first threaded rod 204, the left end surface of the protective case 201 is fixedly connected with the wood cutting machine 1, the upper end surface of the protective case 201 is fixedly connected with the three-phase motor 202, and the end of the main shaft of the three-phase motor 202 is fixedly connected with the first threaded rod 204 The outer side of the first threaded rod 204 is spirally connected with a push rod 203, the lower end of the push rod 203 is fixedly connected with a compression plate 206, the outer sid...

Embodiment 2

[0032] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , the present invention provides a technical solution:

[0033] A wood cutting machine, comprising a wood cutting machine 1, a collecting device 2, a saw blade 3 and a protective device 4, the right end of the wood cutting machine 1 is fixedly connected with a collecting device 2, and the collecting device 2 includes a protective shell 201, a three-phase motor 202, The push rod 203 and the first threaded rod 204, the left end surface of the protective case 201 is fixedly connected with the wood cutting machine 1, the upper end surface of the protective case 201 is fixedly connected with the three-phase motor 202, and the end of the main shaft of the three-phase motor 202 is fixedly connected with the first threaded rod 204 The outer side of the first threaded rod 204 is spirally connected with a push rod 203, the lower end of the push rod 203 is fixedly connected with a compression plate 206, the outer si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com