A kind of uv-pu dual curing 3D printing resin and its preparation method and application

A dual-curing, resin-based technology used in 3D printing materials to address issues such as increased viscosity, restricted usage, and high shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

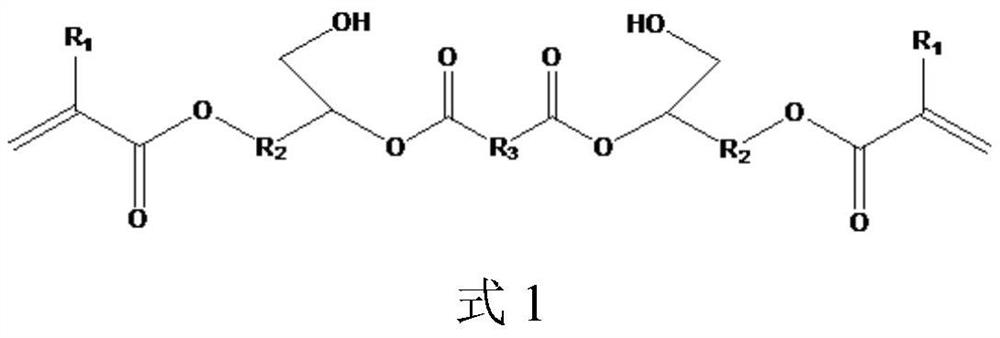

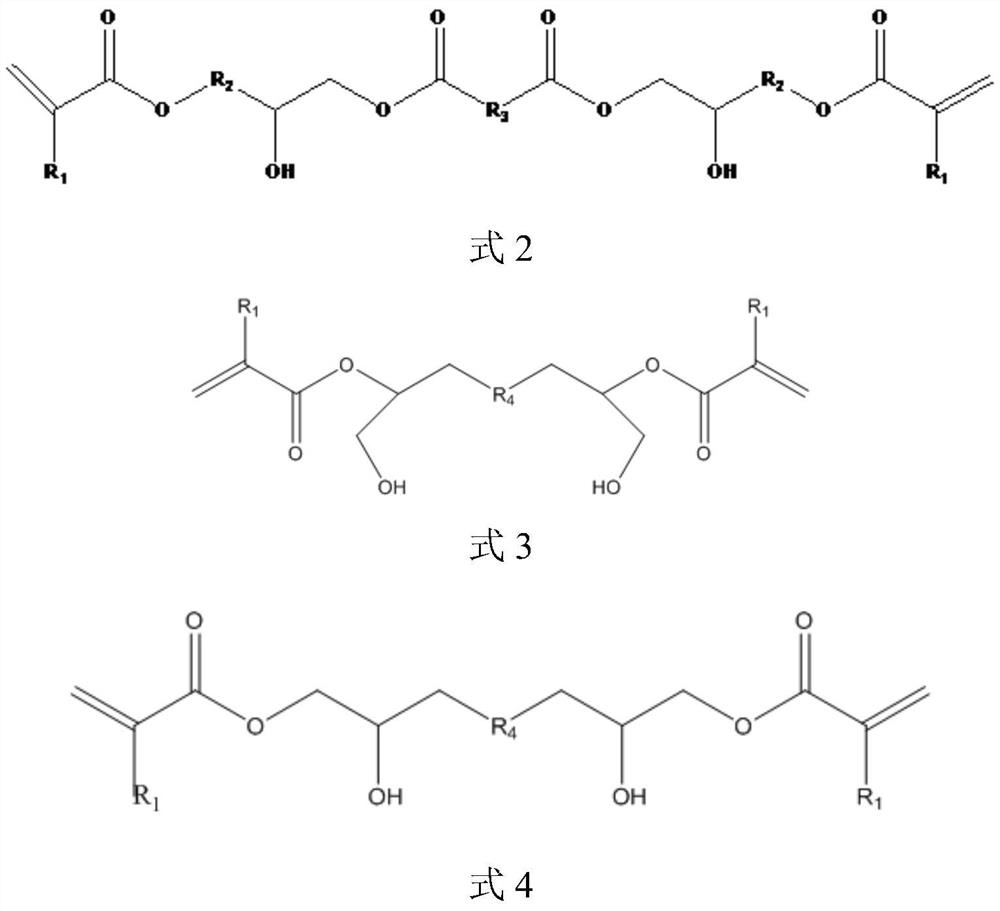

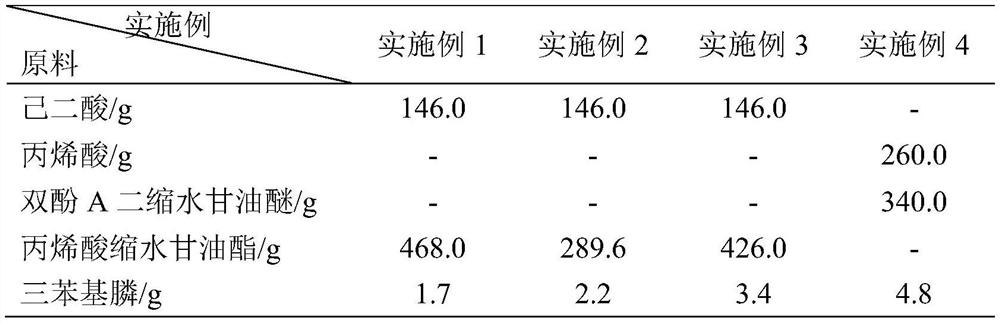

[0021]1, in a four-port flask with 500 ml of the condensed electric thermal and condensed tube, an organic acid, an epoxy monomer, a catalyst, and a polymerization agent is added in Table 1. Heat stirring, the constant temperature of 80 ° C is transparent, warmed to 100 ° C, and continued to react to a acid value below 20-10 mgkOH / g. The prepolymer is at least one of the formulas of formulas.

[0022]2, according to Table 2, the above prepolymer is added to the beaker, and photoinitiators, diluents, and curing agents are added to another beaker, and the light is mixed until the photoinitiator is completely dissolved, poured into the prepolymer, avoiding The light agitated to a transparent uniform state, resulting in resin spare.

[0023]3, use laser stereo printing (SLA) 3D printer, print the standard stretch test spline according to ISO 527 standard. The spline is placed in an oven for 2 h.

[0024]The tensile strength and elongation elongation in this experimental data is based on the IS...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com